Ammonia complex composite capable of selectively reducing ammonia in smoke

An ammonia complex and composite material technology is applied in the field of ammonia complex composite materials that can selectively reduce ammonia in flue gas, can solve problems such as poor selectivity, and achieves low production cost, good selectivity effect, and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

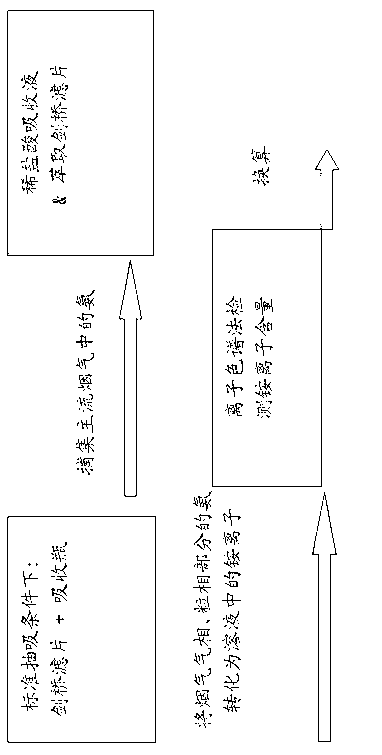

Problems solved by technology

Method used

Image

Examples

Embodiment 1

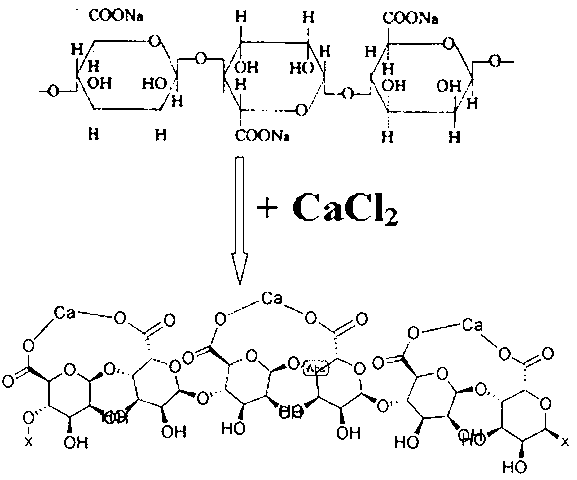

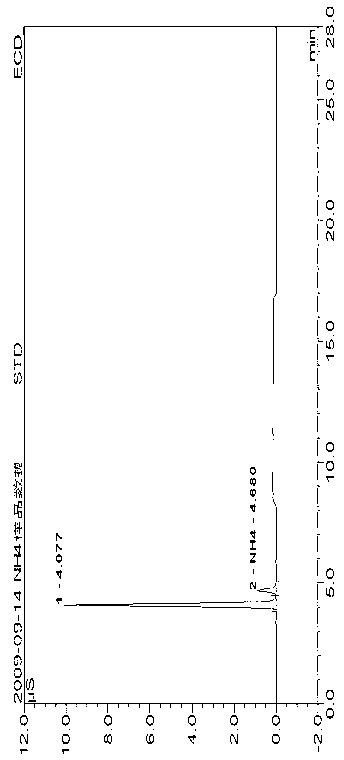

[0020] Weigh 10g of sodium alginate, add 100mL of water, stir thoroughly to make it gelatinous, add gelatinous sodium alginate to 10g CaCl 2 The aqueous solution is stirred rapidly and reacts rapidly to produce alginic acid complexes. The water is filtered off, dried in an oven at 80℃ for 5 hours, and then ground by a grinder to obtain CaCl 2 Composite materials.

Embodiment 2

[0022] Weigh 20g of sodium alginate, add 200mL of water, stir thoroughly to make it gelatinous, add the gelatinous sodium alginate to CaCl 2 25g of aqueous solution, stirred rapidly and reacted quickly to produce alginic acid complex, filtered off the water, dried in an oven at 60℃ for 6h, then grinded by a grinder to obtain CaCl 2 Composite materials.

[0023] Example 1, 2 Synthetic ammonia CaCl 2 There is no significant difference in the ammonia reduction effect of complex composite materials.

Embodiment 3

[0025] Weigh 10g of sodium alginate, add 150mL of water, stir well to make it gelatinous, add the gelatinous sodium alginate to CuCl 2 15g of aqueous solution, stirred rapidly and reacted rapidly to produce alginic acid complex, filtered off the water, dried in an oven at 70℃ for 7 hours, and then ground by a grinder to obtain CuCl 2 Composite materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com