Method for cleaning green tealeaves

A technology for green tea leaves and tea leaves, applied in the field of cleaning green tea leaves, can solve the problems of inability to decompose pesticides, ozone is harmful to human body, pesticide residues in tea leaves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

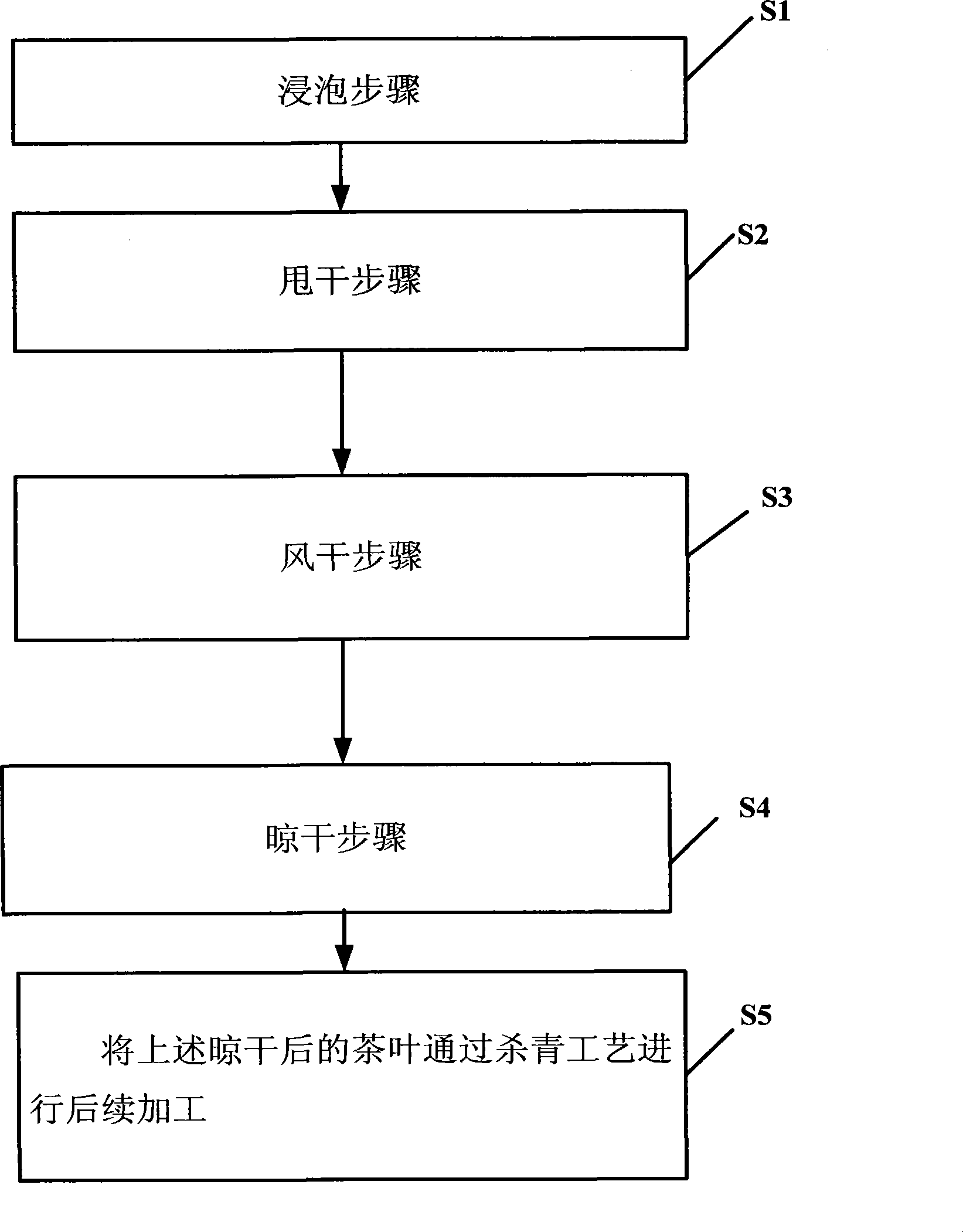

[0031] A method for cleaning green tea leaves, comprising steps:

[0032] 1) The soaking step is as follows: add 18 grams of Biazyme per 500 liters of water, pour 40 kilograms of tea leaves, soak for 0.5 hours, then clean the tea leaves, and then collect them in barrels;

[0033] 2) Drying step Put the tea leaves in the drying equipment and dry them;

[0034] 3) air-drying step utilizes high-speed air-drying equipment to carry out air-drying with the dried tea leaves;

[0035] 4) Drying step puts the air-dried tea leaves on the shelves and spreads them to dry;

[0036] 5) The above-mentioned dried tea leaves are subjected to subsequent processing through a greening process.

[0037] The cleaning of the tea leaves is done by spraying.

[0038] The rotational speed of the drying equipment is 1100r / min.

[0039] The drying step is to put the air-dried tea leaves on the shelves and spread them thinly, and blow them dry with a fan.

Embodiment 2

[0041] A method for cleaning green tea leaves, comprising steps:

[0042] 1) The soaking step is as follows: add 20 grams of Biazyme per 550 liters of water, pour 45 kilograms of tea leaves, soak for 1 hour, then clean the tea leaves, and then collect them in barrels;

[0043] 2) Drying step Put the tea leaves in the drying equipment and dry them;

[0044] 3) air-drying step utilizes high-speed air-drying equipment to carry out air-drying with the dried tea leaves;

[0045] 4) Drying step puts the air-dried tea leaves on the shelves and spreads them to dry;

[0046] 5) The above-mentioned dried tea leaves are subjected to subsequent processing through a greening process.

[0047] The cleaning of the tea leaves is done by spraying.

[0048] The rotational speed of the drying equipment is 1200r / min.

[0049] The drying step is to put the air-dried tea leaves on the shelves and spread them thinly, and blow them dry with a fan.

Embodiment 3

[0051] A method for cleaning green tea leaves, comprising steps:

[0052] 1) The soaking step is as follows: add 22 grams of Biazyme per 600 liters of water, pour 50 kilograms of tea leaves, soak for 1.5 hours, then clean the tea leaves, and then collect them in barrels;

[0053] 2) Drying step Put the tea leaves in the drying equipment and dry them;

[0054] 3) air-drying step utilizes high-speed air-drying equipment to carry out air-drying with the dried tea leaves;

[0055] 4) Drying step puts the air-dried tea leaves on the shelves and spreads them to dry;

[0056] 5) The above-mentioned dried tea leaves are subjected to subsequent processing through a greening process.

[0057] The cleaning of the tea leaves is done by spraying.

[0058] The rotational speed of the drying equipment is 1300r / min.

[0059] The drying step is to put the air-dried tea leaves on the shelves and spread them thinly, and blow them dry with a fan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com