Method for preparing water soluble chitosan oligosaccharide

A technology of water-soluble chitosan and chitosan, which is applied in the preparation of sugar derivatives, chemical instruments and methods, amino sugars, etc., can solve the problems of incomplete degradation process, waste of raw materials, high risk, etc., and achieve microwave degradation The effect of complete degree, reduction of process cost, and shortening of radiation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

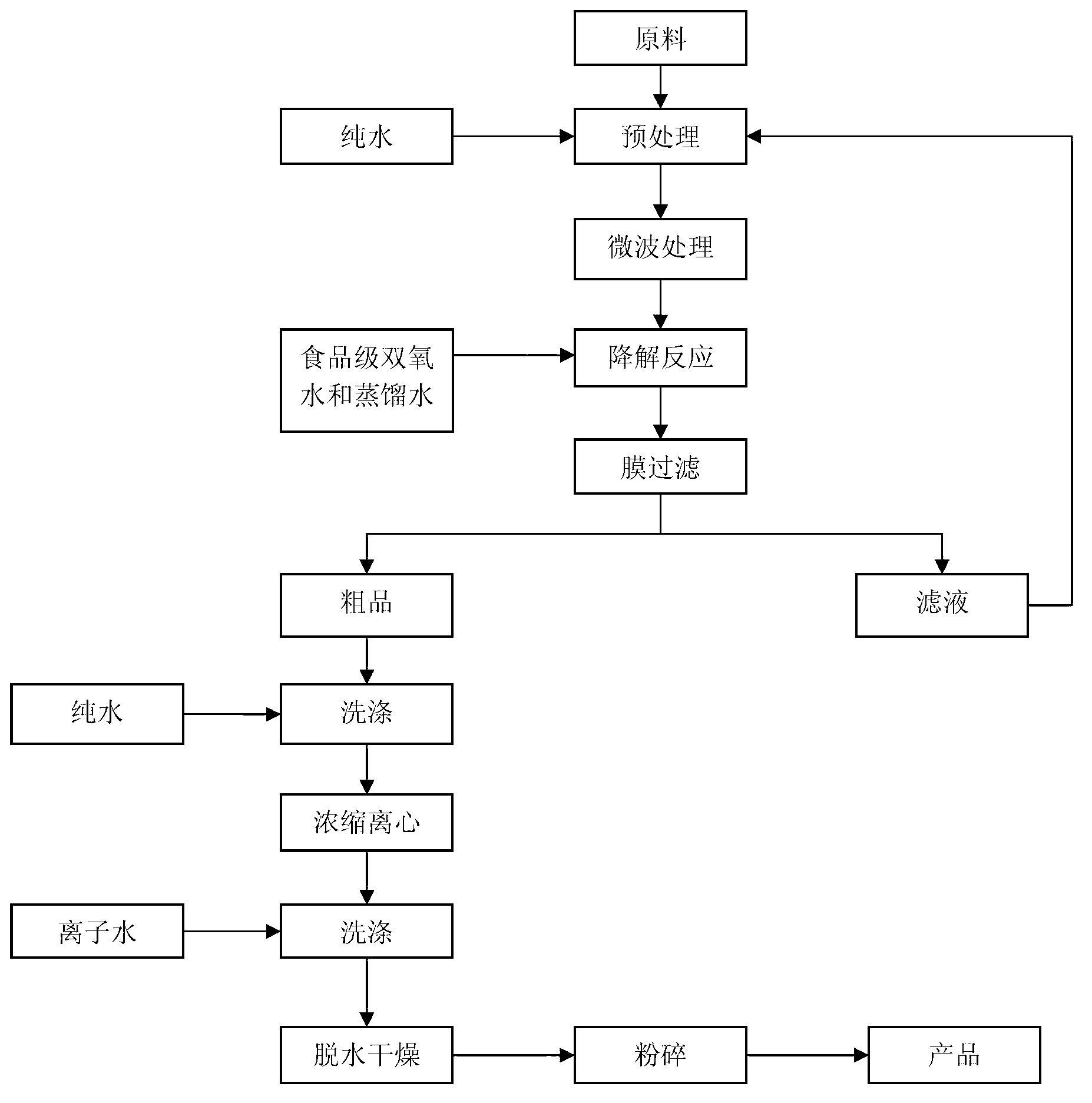

Image

Examples

Embodiment 1

[0014] Soak 1 kg of raw material polymer chitosan in pure water for 6 hours after preliminary treatment to form 1000 ml of chitosan and pure water mixture, and then place the soaked mixture on a microwave generator for tunnel-type continuous microwave Treatment can ensure that the soaked chitosan is subjected to uniform microwave radiation, wherein the time of microwave radiation is 5min, and the temperature of microwave radiation is 130°C; the solution obtained after microwave radiation is degraded with 3000ml of food-grade hydrogen peroxide. Distilled water is added during the degradation process of food-grade hydrogen peroxide. After the reaction is complete, nano-membrane filtration separates the crude chitosan oligosaccharide and the filtrate with low molecular weight. The obtained filtrate can be sent to the soaking process for reuse; the crude chitosan oligosaccharide is washed with pure water to remove impurities , high-speed centrifugation and concentration of the wash...

Embodiment 2

[0016] Soak 1 kg of raw material polymer chitosan in pure water for 8 hours after preliminary treatment to form 1000 ml of chitosan and pure water mixture, and then place the soaked mixture on a microwave generator for continuous tunneling. Microwave treatment can ensure that the soaked chitosan is subjected to uniform microwave radiation. The time of microwave radiation is 30 minutes, and the temperature of microwave radiation is 120°C; the solution obtained after microwave radiation is degraded with 2500ml of food-grade hydrogen peroxide. , Distilled water was added during the degradation process of food-grade hydrogen peroxide. After the reaction was complete, the crude chitosan oligosaccharide and the filtrate with low molecular weight were separated by nano-membrane filtration. The obtained filtrate could be sent to the soaking process for reuse; the crude chitosan oligosaccharide was removed by washing with pure water Impurities, high-speed centrifugation and concentratio...

Embodiment 3

[0018] Soak 1 kg of raw material polymer chitosan in pure water for 10 hours after preliminary treatment to form 1000 ml of chitosan and pure water mixture, and then place the soaked mixture on a microwave generator for continuous tunneling. Microwave treatment can ensure that the soaked chitosan is subjected to uniform microwave radiation. The time of microwave radiation is 60 minutes, and the temperature of microwave radiation is 100°C; the solution obtained after microwave radiation is degraded with 2000ml of food-grade hydrogen peroxide. , Distilled water is added during the degradation process of food-grade hydrogen peroxide. After the reaction is complete, the crude chitosan oligosaccharide with low molecular weight and the filtrate are separated by nano-membrane filtration. The obtained filtrate can be sent to the soaking process for reuse; the crude chitosan oligosaccharide is washed with pure water Remove impurities, centrifuge and concentrate the washed solution at hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com