Environment-friendly waste road asphalt regenerating agent and preparation method thereof

A technology of waste asphalt and rejuvenating agent, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of low cost performance, high price, and unenvironmental protection of rejuvenating agent, and achieve the effect of high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Simultaneously, the present invention also provides a kind of preparation method of environment-friendly type road waste asphalt regeneration agent, described method comprises the steps:

[0037] A. Preheat the reactor and raise the temperature to 110-170°C, add 45-75 parts by weight of regeneration components into the reactor, and stir for 20-50 minutes;

[0038] B. After the stirring is completed, add 25 to 55 parts by weight of waste styrene-butadiene rubber powder, control the temperature at 160 to 200 ° C, and stir for 70 to 100 minutes;

[0039] C. After the stirring is completed, gradually lower the temperature to 80-120°C, add 1-5 parts by weight of plasticizer and 0.5-3 parts by weight of anti-waste agent in turn, stir for 25-45 minutes, then gradually cool to room temperature, and finally get the obtained Environmentally friendly road waste asphalt regenerant.

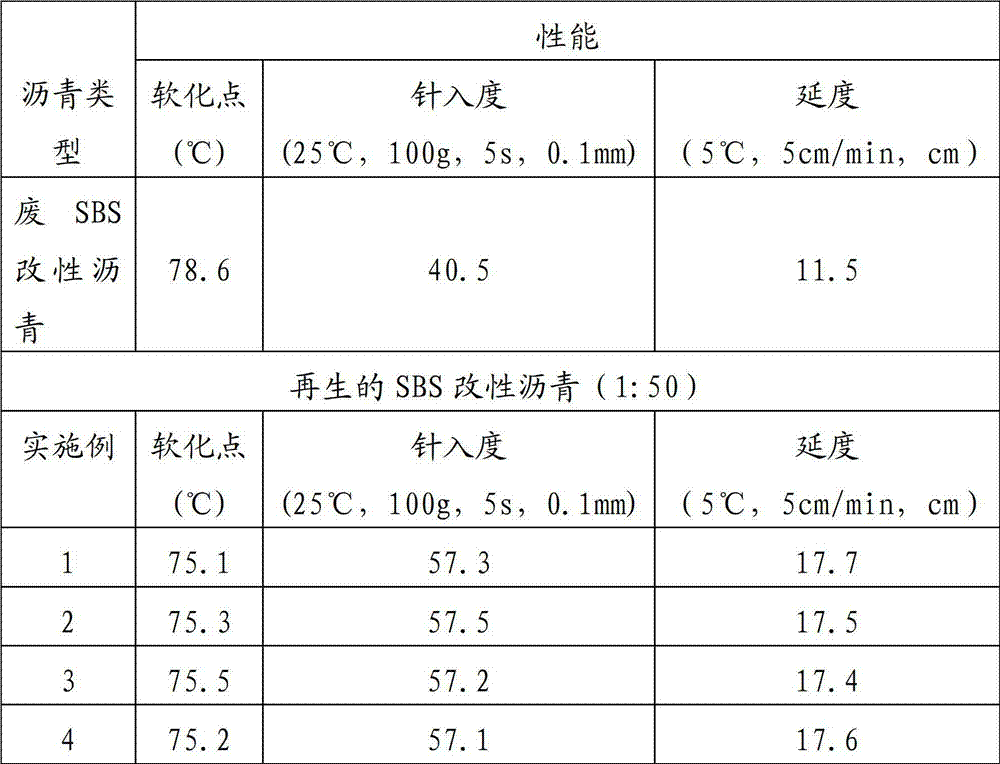

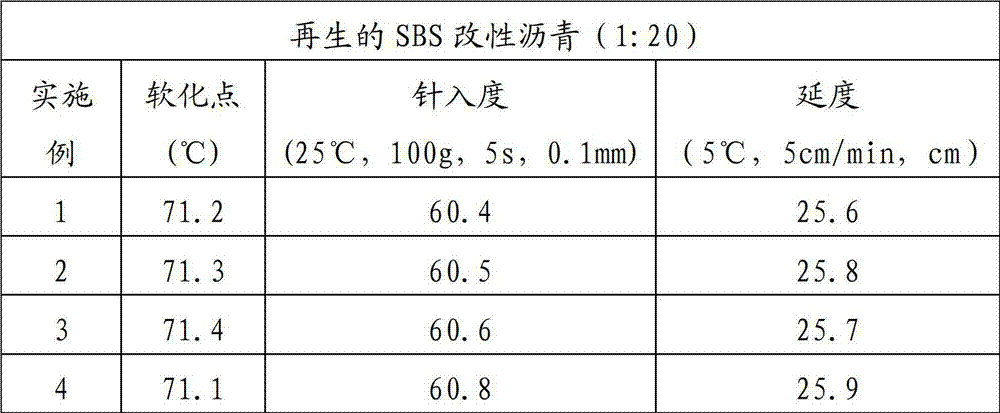

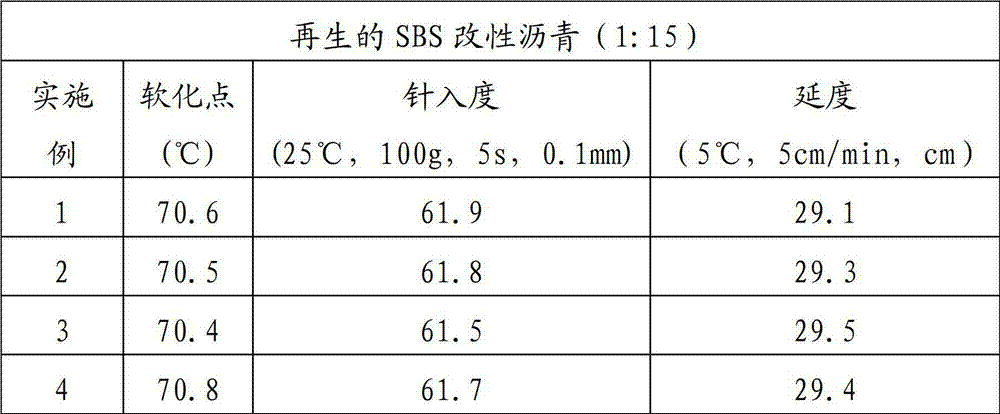

[0040]The present invention will be further described in conjunction with specific implementation ...

Embodiment 1

[0042] First, preheat the reactor. After the temperature of the reactor is preheated to 165°C, weigh 60 parts of oil processed and refined from inferior poultry fat in parts by weight, put it into the reactor and stir it rapidly for 40 minutes; then weigh the waste butylbenzene in proportion 36 parts of rubber powder, the particle size of the waste styrene-butadiene rubber powder is 60-80 mesh, put into the reaction kettle, heat to 180°C, and stir rapidly for 85min; then gradually cool down to 110°C, add 3 parts of phthalic acid dicarboxylate in sequence Octyl ester and 1 part of tert-butyl hydroquinone, continue to stir rapidly for 30 minutes, and then gradually cool to room temperature to obtain an environmentally friendly road waste asphalt regenerant.

Embodiment 2

[0044] First, preheat the reaction kettle. After the temperature of the reaction kettle is preheated to 110°C, weigh 50 parts by weight of the oil processed and refined from the greasy floating matter in the sewer, put it into the reaction kettle and stir it quickly for 30 minutes; then weigh the waste in proportion. 45 parts of styrene-butadiene rubber powder, the particle size of the waste styrene-butadiene rubber powder is 70-90 mesh, put it into the reaction kettle, heat it to 190°C, and stir it rapidly for 90min; then gradually cool down to 120°C, add 4.5 parts of terephthalate Ethylene glycol formate and 0.5 parts of tert-butyl hydroquinone were stirred rapidly for 35 minutes, and then gradually cooled to room temperature to obtain an environmentally friendly road waste asphalt regenerant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com