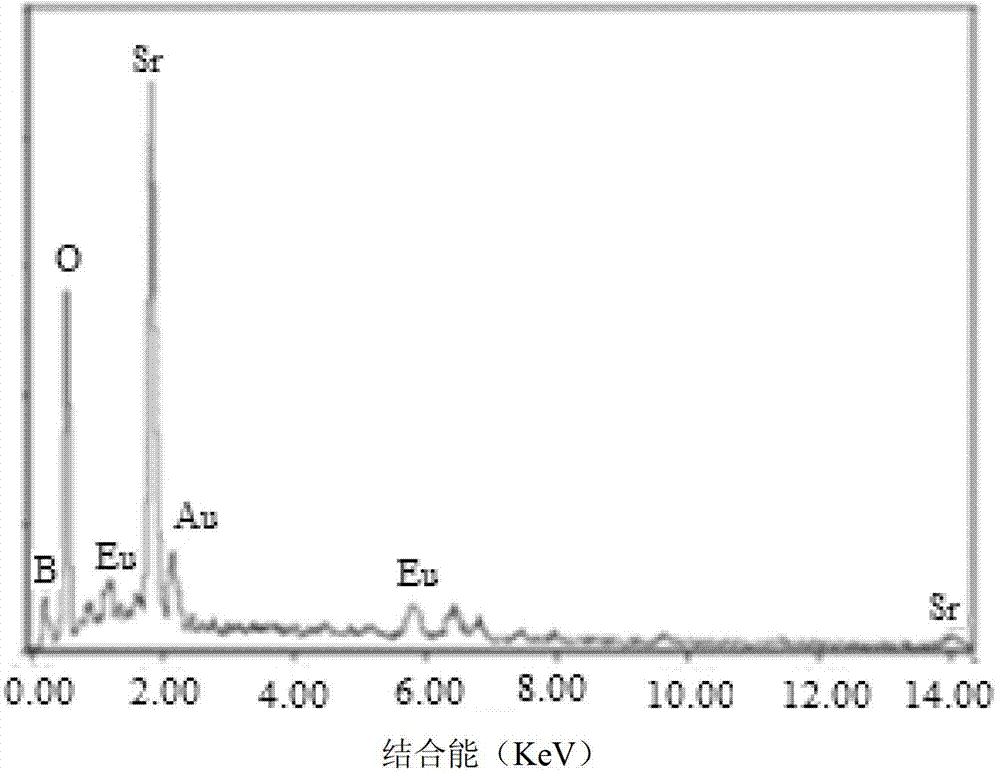

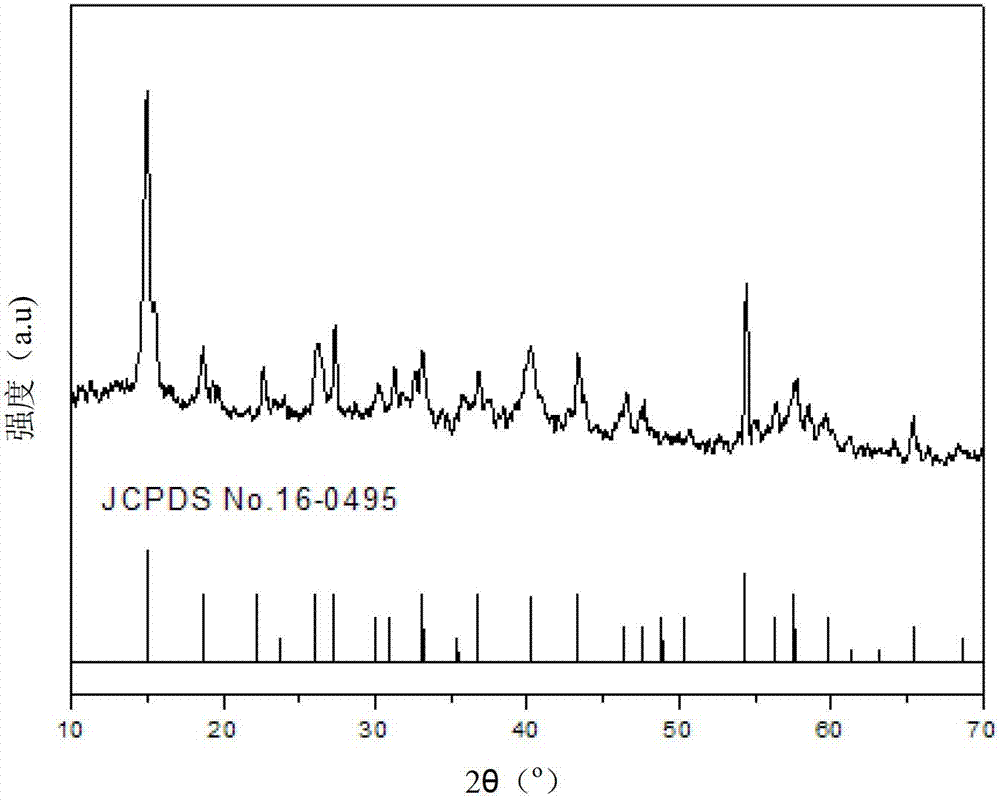

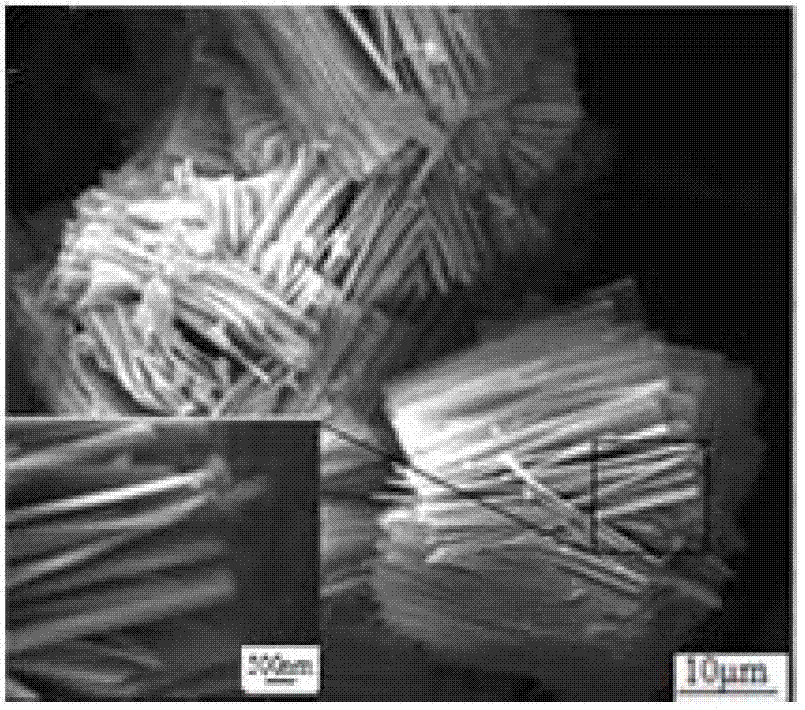

Preparation method for SrB6O10/5H2O:Eu<3> luminous material

A srb6o10·5h2o, luminescent material technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of affecting color purity and luminous intensity, affecting luminescent performance, reducing luminous intensity, etc., to achieve high rare earth ion quenching concentration, The effect of easy availability of raw materials and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] With raw material Sr(OH) 2 ·8H 2 O5.3g is example, preparation SrB 6 o 10 ·5H 2 O: Eu 3+ The method for the luminescent material consists of the following steps:

[0045] (1) Weigh 5.3g Sr(OH) 2 ·8H 2 O with 0.45g Eu(NO 3 ) 3 ·6H 2 O placed in 180mL deionized water, Sr(OH) 2 ·8H 2 O, Eu(NO 3 ) 3 ·6H 2 The molar ratio of O to deionized water is 1:0.05:500, heated at 80°C for 30 minutes;

[0046] (2) Weigh 15g H 3 BO 3 and 2.0 g Na 2 B 4 o 7 10H 2 Dissolve O in 200mL of deionized water until completely dissolved, add it to the heated mixture in step (1), add 1.45g of cetyltrimethylammonium bromide (CTAB), Sr(OH) 2 ·8H 2 O, H 3 BO 3 、Na 2 B 4 o 7 10H 2 The molar ratio of O and cetyltrimethylammonium bromide (CTAB) was 1:12:0.25:0.2, heated at 60 °C for 30 min, ultrasonicated at 60 °C for 1 h at 60 Hz, and transferred to a closed reactor React at 80°C for 12 hours;

[0047] (3) The reaction product of step (2) was separated by suction filtratio...

Embodiment 2

[0049] With raw material Sr(OH) 2 ·8H 2 O5.3g is example, preparation SrB 6 o 10 ·5H 2 O: Eu 3+ The method for the luminescent material consists of the following steps:

[0050] (1) Weigh 5.3g Sr(OH) 2 ·8H 2 O with 0.18g Eu(NO 3 ) 3 ·6H 2 O placed in 140mL deionized water, Sr(OH) 2 ·8H 2 O, Eu(NO 3 ) 3 ·6H 2 The molar ratio of O to deionized water is 1:0.02:400, heated at 80°C for 30 minutes;

[0051] (2) Weigh 12.5g H 3 BO 3 and 2.0 g Na 2 B 4 o 7 10H 2 Dissolve O in 200mL of deionized water until completely dissolved, add it to the heated mixture in step (1), add 1.45g of cetyltrimethylammonium bromide (CTAB), Sr(OH) 2 ·8H 2 O and H 3 BO 3 、Na 2 B 4 o 7 10H 2 O. The molar ratio of cetyltrimethylammonium bromide (CTAB) is 1:10:0.25:0.2, heated at 60°C for 30 minutes, ultrasonicated at 60°C for 1 hour, and the ultrasonic frequency is 60Hz, transferred to a closed reactor React at 80°C for 12 hours;

[0052] Other steps are identical with embodimen...

Embodiment 3

[0054] With raw material Sr(OH) 2 ·8H 2 O5.3g is example, preparation SrB 6 o 10 ·5H 2 O: Eu 3+ The method for the luminescent material consists of the following steps:

[0055] (1) Weigh 5.3g Sr(OH) 2 ·8H 2 O with 0.70g Eu(NO 3 ) 3 ·6H 2 O placed in 220mL deionized water, Sr(OH) 2 ·8H 2 O, Eu(NO 3 ) 3 ·6H 2 The molar ratio of O to deionized water is 1:0.08:600, heated at 80°C for 30 minutes;

[0056] (2) Weigh 16g H 3 BO 3 and 2.0 g Na 2 B 4 o 7 10H 2 Dissolve O in 200mL of deionized water until completely dissolved, add it to the heated mixture in step (1), add 1.45g of cetyltrimethylammonium bromide (CTAB), Sr(OH) 2 ·8H 2 O and H 3 BO 3 、Na 2 B 4 o 7 10H 2 O. The molar ratio of cetyltrimethylammonium bromide (CTAB) is 1:13:0.25:0.2, heated at 60°C for 30 minutes, ultrasonicated at 60°C for 1 hour, and the ultrasonic frequency is 60Hz, transferred to a closed reactor React at 80°C for 12 hours;

[0057] Other steps are identical with embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com