Centrifugal composite high-nickel-niobium wear-resisting cast iron roll and casting method thereof

A technology of centrifugal compounding and wear-resistant cast iron, which is applied in the casting field of cast iron rolls, which can solve the problems of graphite spalling, segregation of tissue components, and low rolling volume of rolls in millimetres, and achieve the effect of reducing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

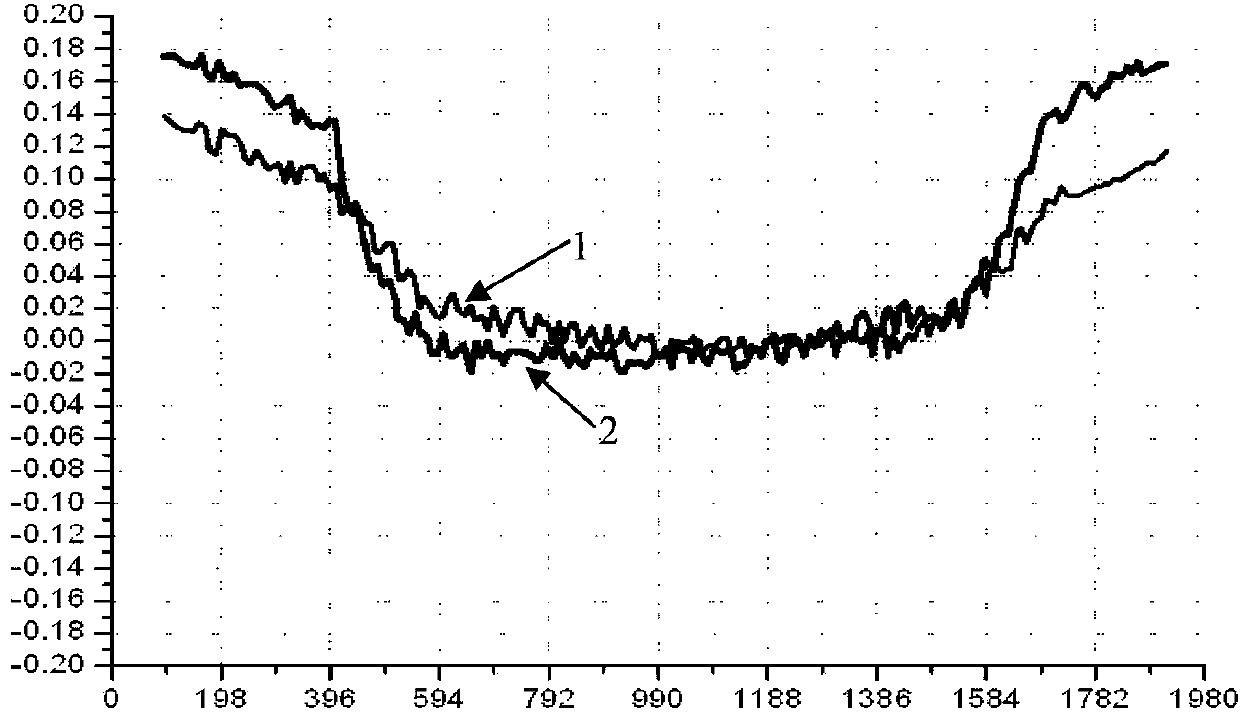

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0030] The casting method of a centrifugal compound high-nickel-niobium wear-resistant cast iron roll of the present invention adopts centrifugal compound casting, including tooling preparation, molten iron smelting, molten iron treatment, molten iron pouring, cooling and unpacking, heat treatment, and processing inspection and other processes, wherein:

[0031] 1. Tooling preparation:

[0032] ① Crash the sand molds of the riser box and the base box, control the thickness of the sand at about 50-150mm, and the drying time> 8h;

[0033] ② Fit the pouring funnel above the riser box;

[0034] ③Fix the base box horizontally in the ditch;

[0035] ④ Crash the sand mold of the end cover box and assemble it at both ends of the cold mold;

[0036] ⑤ Place the cold type on the centrifuge, and hang the cold type paint, and the thickness of the paint is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com