Reaction chamber air inlet device for metal organic chemical vapor deposition (MOCVD) equipment

A metal-organic chemistry, vapor deposition technology, applied in the direction of chemical reactive gas, gaseous chemical plating, chemical instruments and methods, etc., can solve the problem of dense distribution of uniform pores or slits, waste of impurities and sources, increase Reaction and other issues, to achieve the effect of improving flexibility and versatility, convenient automatic control, and avoiding pre-reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

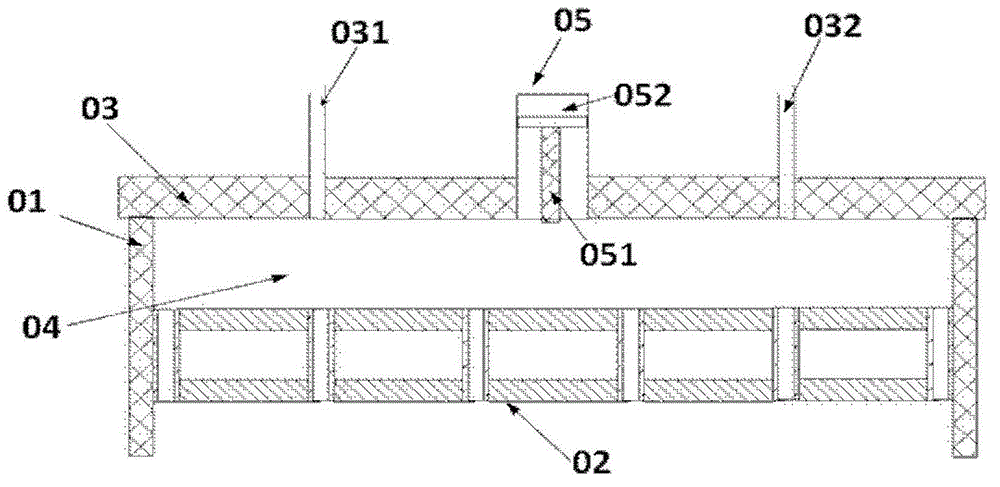

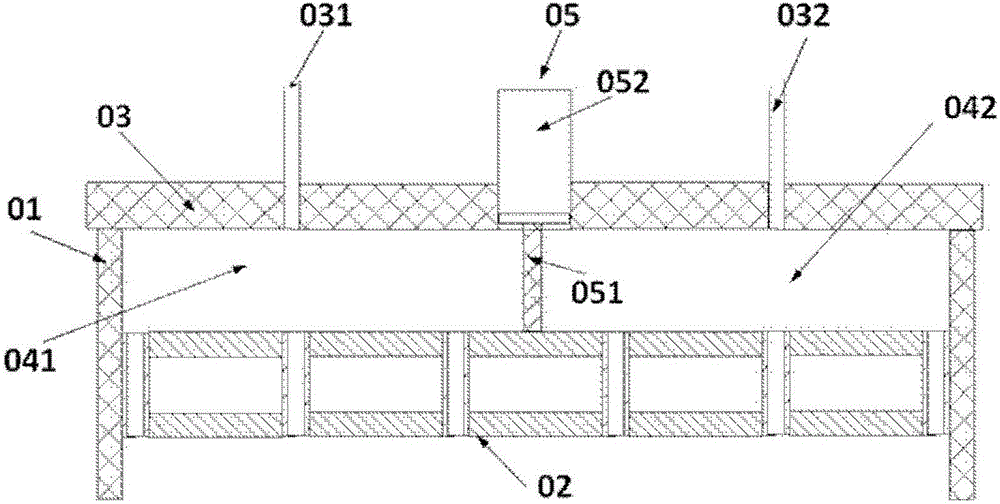

[0017] The present invention will be further described below in conjunction with the embodiments and with reference to the accompanying drawings. figure 1 , figure 2 It is a schematic diagram of a specific embodiment of the present invention, and it should be understood that the drawings of the present disclosure focus on the structural features according to an embodiment of the present invention, and these drawings are not intended to show every single component in the device. see figure 1 , figure 2 As shown, the present invention provides a reaction chamber intake device for metal organic chemical vapor deposition equipment, comprising:

[0018] A cylinder 01, which is used as the side wall of the top plate of the reaction chamber; a water-cooled gas uniform plate 02, which is made in the cylinder 01; an upper cover plate 03, which is fixed on the cylinder 01 Above, an air inlet chamber 04 is formed between the upper cover plate 03, the water-cooled gas uniform plate 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com