Deep decompression anatonosis type vacuum preloading foundation treatment method

A foundation treatment and vacuum technology, applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of uneven foundation bearing capacity, poor drainage treatment effect, low bearing capacity of the lower part, etc. The effect of shortening construction period and increasing drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

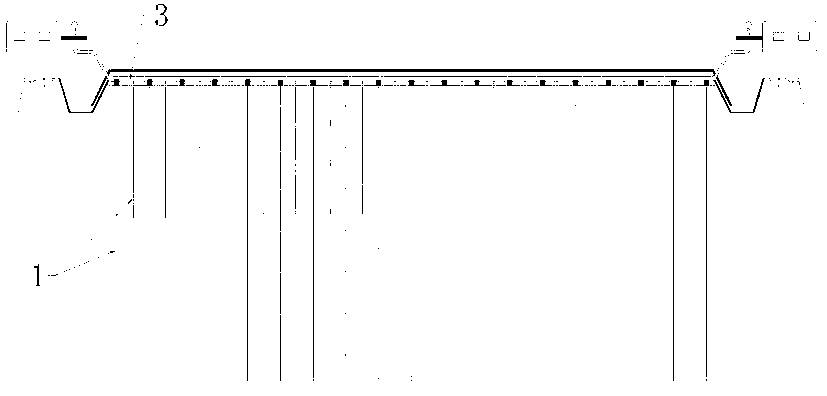

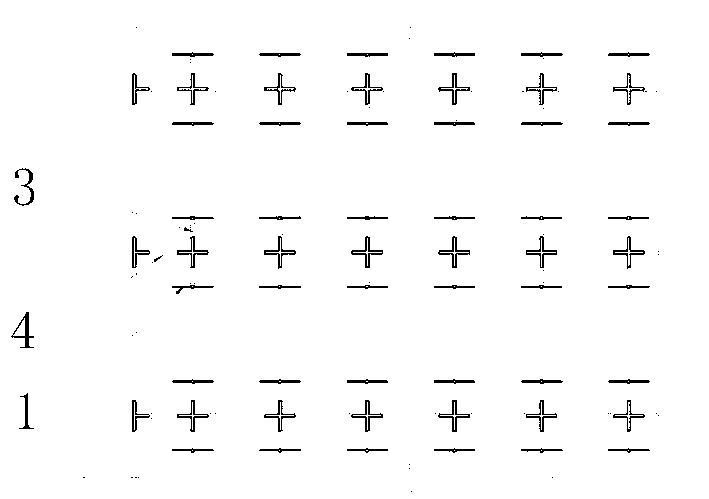

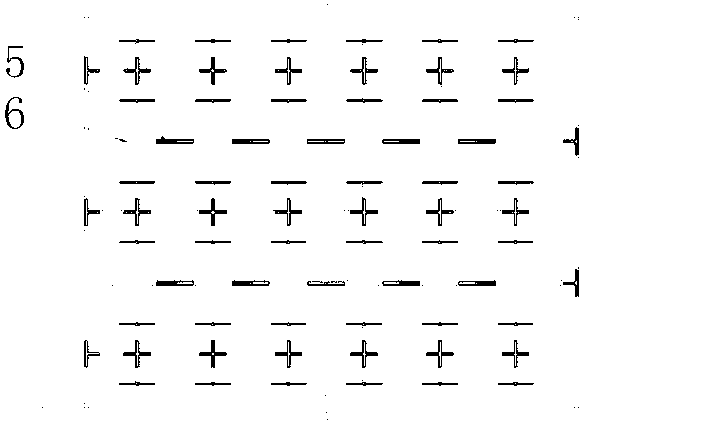

[0011] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the deep-layer decompression and infiltration-increasing vacuum preloading foundation treatment method provided by the present invention includes step a, after laying the first geotextile, setting the plastic drainage board 1 in the soil, and passing the plastic drainage board 1 in the soil The sealing joint is connected to the airtight sealing water pipe 3, and then each sealing water pipe 3 is connected to the airtight sealing main pipe 4 to form a vacuum system of the plastic drainage board in the soil; Injection pipe 5, the injection pipe 5 is connected to the injection branch pipe 6 under the first geotextile, all the injection branch pipes 6 are connected to the main injection pipe, and the main injection pipe is connected to the feeding device, which is generally a grouting machine ; c, adopt feeding device to drop dehydrating agent into material injection pipe, the dehydrating agent dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com