Decorative plate with purple decorative thin film and preparation method of decorative plate

A decorative film and decorative board technology, applied in covering/lining, construction, building construction, etc., can solve the problems of narrowing the selection range of base materials and high temperature, and achieve the effect of low production cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

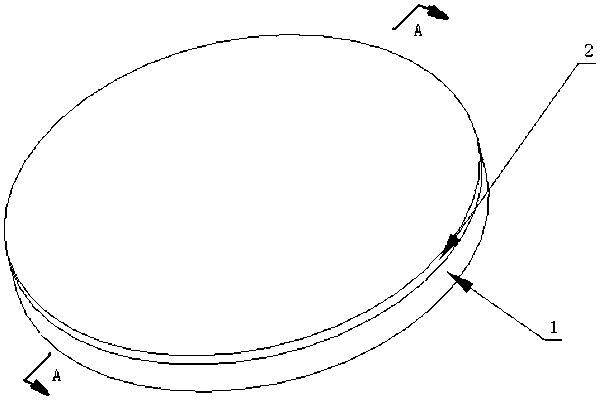

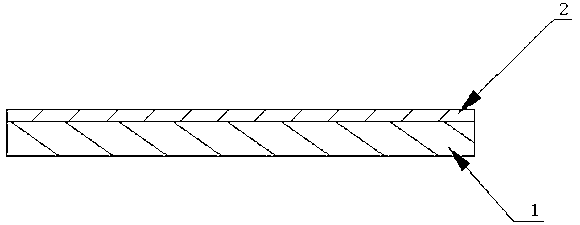

[0031] A decorative plate with a purple decorative film, which is a layered structure, and its structure schematic diagram is shown in figure 1 As shown, it includes a bottom substrate 1 and a purple decorative film 2 prepared on the bottom substrate 1 by a magnetron sputtering method, and the thickness of the purple decorative film 2 is a cerium oxide film of 30nm;

[0032] The bottom substrate is glass.

[0033] The above-mentioned preparation method of a decorative plate with a purple decorative film specifically includes the following steps:

[0034] (1) Cleaning of the bottom substrate glass substrate

[0035] Put the bottom substrate glass substrate into high-purity alcohol, clean it with ultrasonic for 5 minutes, then put it into acetone solution, clean it with ultrasonic for 5 minutes, then dry it, and put it into the vacuum chamber for 30 minutes immediately ion cleaning;

[0036] (2), preparation of cerium oxide film

[0037] Using JGP-450 multi-target magnetron ...

Embodiment 2

[0042] A decorative plate with a purple decorative film, which is a layered structure, includes a bottom substrate and a purple decorative film prepared on the bottom substrate by magnetron sputtering, and the thickness of the purple decorative film is 40nm cerium oxide film;

[0043] The base material is glass.

[0044] The above-mentioned preparation method of a decorative plate with a purple decorative film specifically includes the following steps:

[0045] (1), the cleaning of the bottom substrate glass substrate is the same as in Example 1;

[0046] (2) Preparation of cerium oxide film

[0047] Using JGP-450 multi-target magnetron sputtering apparatus, magnetron sputtering is carried out on the bottom substrate glass substrate cleaned in step (1) to prepare a purple decorative film, that is, a cerium oxide film, and finally a purple decorative film is obtained. Film decorative panels;

[0048] The above-mentioned magnetron sputtering uses metal cerium target (purity 99...

Embodiment 3

[0052] A decorative plate with a purple decorative film is a layered structure, including a bottom substrate and a purple decorative film prepared on the bottom substrate by magnetron sputtering, and the thickness of the purple decorative film is 50nm cerium oxide film;

[0053] The bottom substrate is glass.

[0054] The above-mentioned preparation method of a decorative plate with a purple decorative film specifically includes the following steps:

[0055] (1), the cleaning of the bottom substrate glass substrate is the same as in Example 1;

[0056] (2) Preparation of cerium oxide film

[0057] Using JGP-450 multi-target magnetron sputtering apparatus, magnetron sputtering is carried out on the bottom substrate glass substrate cleaned in step (1) to prepare a purple decorative film, that is, a cerium oxide film, and finally a purple decorative film is obtained. Film decorative panels;

[0058] The above-mentioned magnetron sputtering uses metal cerium target (purity 99....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com