Novel 3D (three-dimensional) optical diaphragm and preparation method

A three-dimensional film, optical technology, applied in chemical instruments and methods, optics, optical components, etc., can solve the problems of large ghosting, light output, halving of brightness, small viewpoint width, etc., to reduce ghosting, water oxygen, etc. Good barrier properties and the effect of increasing transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

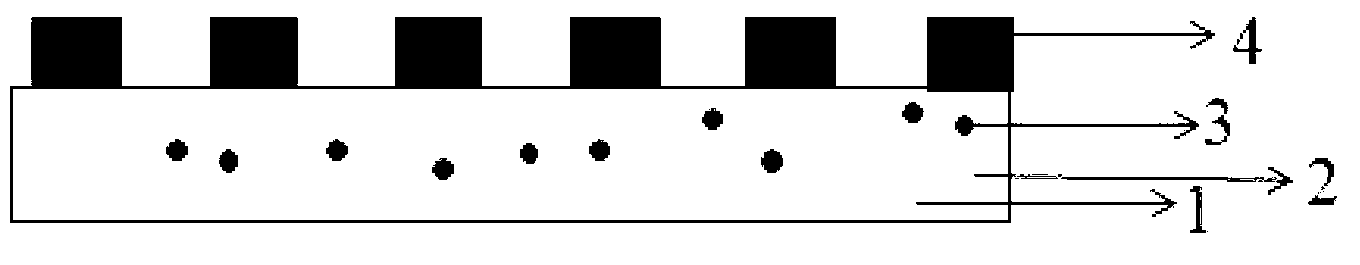

[0029] Such as figure 1 As shown, the zinc oxide nanoparticles 2 were first prepared by the sol-gel method, and the size of the zinc oxide nanoparticles was 20 nm. Secondly, zinc oxide nanoparticles are mixed in the proportion of 4% and 1,8-diiodooctane additive in the proportion of 0.1% by weight in the polyethylene terephthalate (PET) material, which is used in co-extrusion casting The PET transparent film layer 1 was prepared by co-extrusion molding on an extruder, and then cut into finished products after 72 hours of resting. The thickness of the transparent film layer was 0.01 mm. Finally, the slit grating layer 3 is prepared on the PET film material layer by using an inkjet printing method and using electronic ink. The width of the slit grating is Wherein, i is the interpupillary distance of the human eye; a is the pixel width of the display device, and the width between the grid bars is the same as the grid bar width.

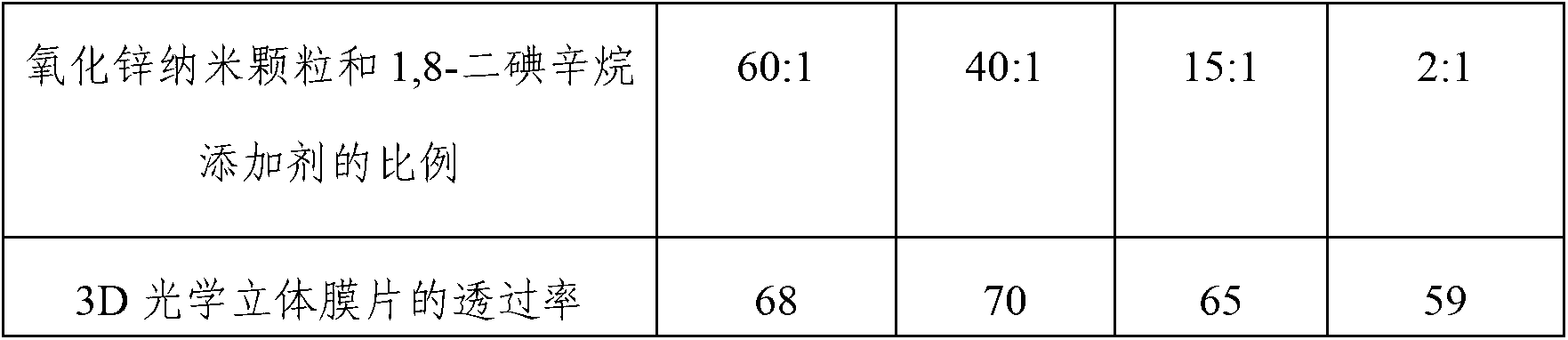

[0030] Table 1

[0031] Transmittanc...

Embodiment 2

[0040] Such as figure 1As shown, zinc oxide nanoparticles 2 were first prepared by the alkoxide hydrolysis method, and the size of the zinc oxide nanoparticles was 100 nm. Secondly, the zinc oxide nanoparticles are mixed in the polyethylene (PE) material according to the weight ratio of 6.2% and the 1,8-diiodooctane additive according to the weight ratio of 3%, and co-extruded on the co-extrusion casting extruder Molding method The transparent film material layer 1 of PE is prepared, and then cut into finished products after 72 hours of stilling. The thickness of the transparent film material layer is 2 mm. Finally, the inkjet printing method is used to prepare the slit grating layer 3 on the PE film material layer using electronic ink. The width of the slit grating is Wherein, i is the interpupillary distance of the human eye; a is the pixel width of the display device, and the width between the grid bars is the same as the grid bar width.

Embodiment 3

[0042] Such as figure 1 As shown, first, zinc oxide nanoparticles 2 were prepared by a hydrothermal method, and the size of the zinc oxide nanoparticles was 1 nm. Secondly, the zinc oxide nanoparticles are mixed in the proportion of 4.5% by weight, and the 1,8-diiodooctane additive is mixed in the polyethylene naphthalate (PEN) material in the proportion of 2%. The transparent film layer 1 of PEN was prepared by co-extrusion on an extruder, and then cut into finished products after 72 hours of stilling. The thickness of the transparent film layer was 5mm. Finally, an inkjet printing method is used to prepare a slit grating layer 3 on the PEN film material layer using electronic ink. The width of the slit grating is Wherein, i is the interpupillary distance of the human eye; a is the pixel width of the display device, and the width between the grid bars is the same as the grid bar width.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com