Supporting design specialist system for bolt-grouting of coal mine soft rock tunnel

An expert system and soft rock technology, applied in the field of expert systems for bolting and grouting support design of soft rock roadways in coal mines, can solve problems such as the inability to design reasonable, accurate and standardized bolting and grouting support schemes and parameters for soft rock roadways in coal mines, and achieve Ensure scientificity and rationality, reduce errors, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

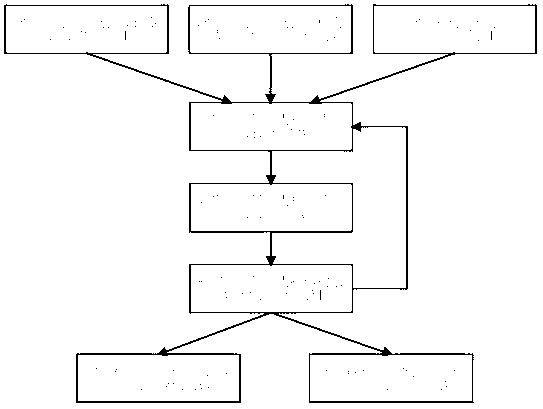

[0017] Example 1: In figure 1 Among them, the expert system includes: soft rock roadway anchoring and grouting support design expert knowledge base module Ⅰ, soft rock roadway anchoring and grouting support engineering practice successful case database module Ⅱ, new soft rock roadway engineering original data input module Ⅲ, soft rock roadway Anchoring support form reasoning design module IV, soft rock roadway anchoring support parameter reasoning design module V, soft rock roadway anchoring support structure bearing capacity module VI, soft rock roadway anchoring support design report automatic generation module VII and Module Ⅷ for graphic drawing of anchoring and grouting support construction layout in soft rock roadway. The above 8 modules are described in detail below in conjunction with the accompanying drawings:

[0018] Soft rock roadway anchoring and grouting support design expert knowledge base module Ⅰ: mainly used to obtain the design experience and knowledge of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com