Vacuum diode with high current, small focal spot and long service life

A vacuum diode and long-life technology, applied in X-ray tubes with huge currents, X-ray tube electrodes, X-ray tube components, etc., can solve the problem of inability to meet the requirements of refined imaging, and the structure of cathode and anode components does not meet the pinch Conditions, unsuitable for pulse imaging and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

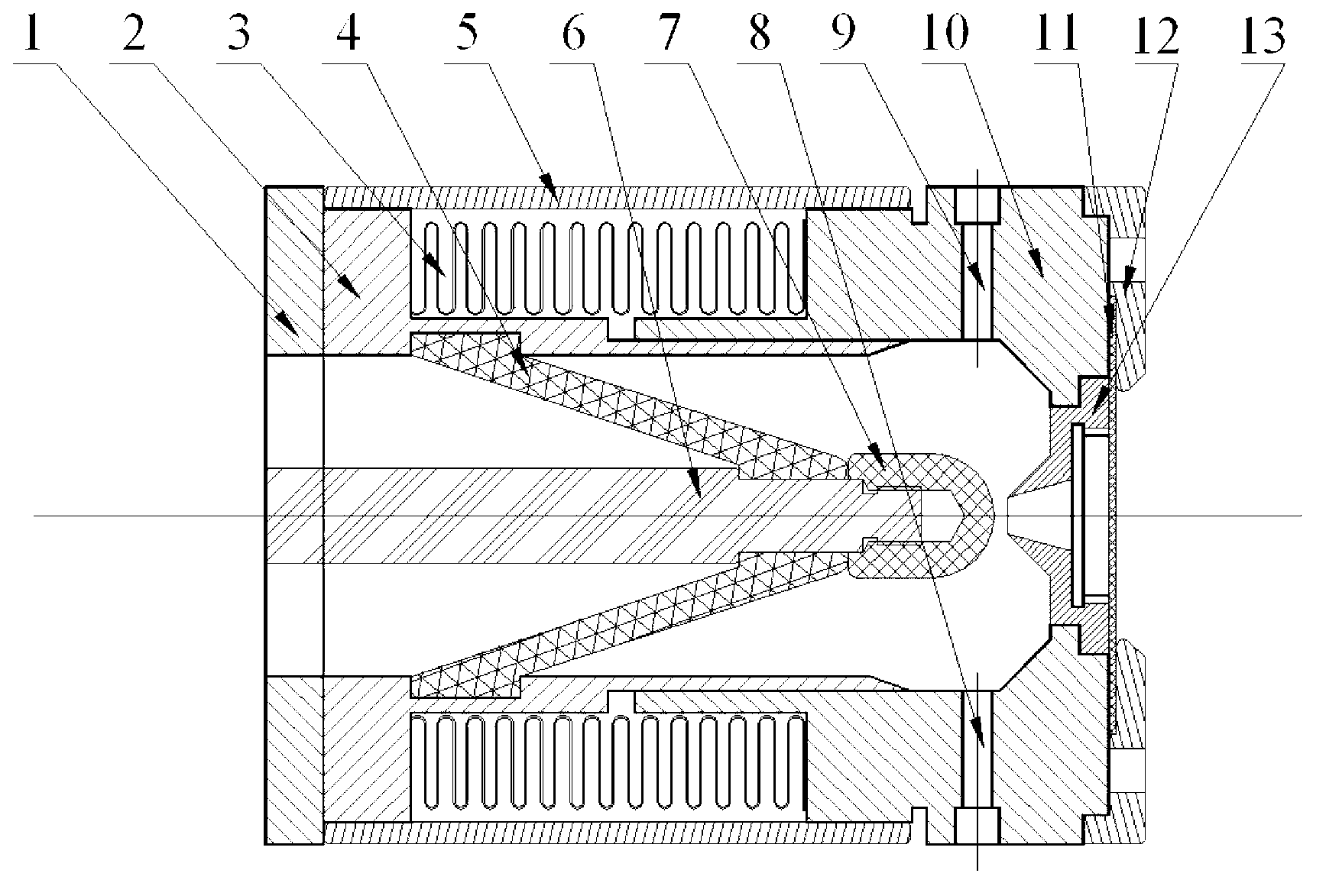

[0037] A high-current small focal spot long-life vacuum diode, comprising an outer cylinder 5, a flange 1 arranged at one end of the outer cylinder 5, a pressure ring 12 arranged at the other end of the outer cylinder 5, a sealing baffle 1, and an inner cylinder arranged at the outer cylinder 5 1. The cathode and anode components arranged in the inner cylinder; the inner cylinder includes a cylindrical fixed support 2, a cylindrical dynamic support 10, and a bellows 3; the fixed support 2 is arranged in the outer cylinder 5 and is fixedly connected with the flange 1, and the dynamic support 10 It is arranged in the outer cylinder 5 and is fixedly connected with the pressure ring 12. The bellows 3 is arranged in the cavity between the fixed support 2, the dynamic support 10 and the outer cylinder 5, and the two ends are respectively connected with the fixed support and the dynamic support. 2. The movable support 10, the bellows 3, and the cathode and anode components form a radi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com