A kind of defect structure lifepo4 surface modification layer-spinel composite lithium-rich positive electrode material and its preparation method

A lithium-rich cathode material and surface modification technology, applied in structural parts, battery electrodes, electrical components, etc., can solve the problems of no electrochemical activity, reduced material discharge capacity, limited rate characteristics, etc., and achieve good reversibility. , high capacity, the effect of reducing irreversible capacity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

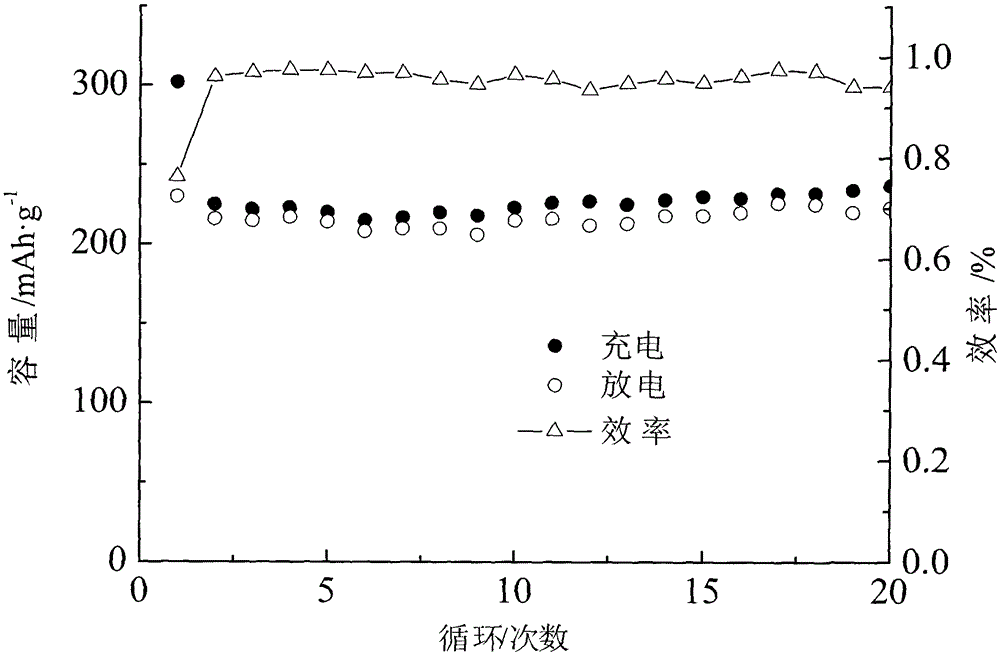

Embodiment 1

[0013] Example 1: LiNO 3 :Mn(CH 3 COO) 2 4H 2 O:Ni(CH 3 COO) 2 4H 2 The ratio of O=0.6: 0.75: 0.25 (molar ratio) is uniformly mixed, dissolved in deionized water, and the amount of the added substance is 1.2 times of the total amount of all metal ions. The tartaric acid is fully stirred until completely dissolved; the temperature of the system is raised to 70 °C Stirring was continued until 71% of the water evaporated, at which point the solution gradually became viscous and formed a jelly. The jelly-like substance was dried in an oven at 130° C. for 22 hours and then ground in a mortar for 10 minutes. The obtained powder was heated up to 500°C at a rate of 2°C / min in a tube furnace and calcined at this temperature for 3 hours. After cooling, the powder was taken out and continued to grind in a mortar for 10 minutes, and the powder was pressed with a pressure of 100MPa. After being formed into a sheet, the temperature was raised to 850° C. for 5 hours in a tube furnace ...

Embodiment 2

[0014] Example 2: LiNO 3 :Mn(CH 3 COO) 2 4H 2 O:Ni(CH 3 COO) 2 4H 2The ratio of O=1.0: 0.75: 0.25 (molar ratio) is evenly mixed, dissolved in deionized water, and the amount of the added substance is 1.6 times of the total amount of all metal ions, and the tartaric acid is fully stirred until completely dissolved; the temperature of the system is raised to 80 °C Stirring was continued until 75% of the water evaporated, at which point the solution gradually became viscous and formed a jelly. The jelly-like substance was dried in an oven at 150° C. for 40 hours and then ground in a mortar for 20 minutes. The obtained powder was heated up to 550°C at a rate of 5°C / min in a tube furnace and calcined at this temperature for 4 hours. After cooling, the powder was taken out and continued to grind in a mortar for 20 minutes, and the powder was pressed with a pressure of 200MPa. Form into a sheet, then heat up to 900° C. for 5 hours in a tube furnace at a rate of 5° C. / min and c...

Embodiment 3

[0015] Example 3: CH 3 COOLi:Mn(CH 3 COO) 2 4H 2 O:Ni(CH 3 COO) 2 4H 2 The ratio of O=0.7: 0.75: 0.25 (molar ratio) is uniformly mixed, dissolved in deionized water, and the amount of the added substance is tartaric acid 2.0 times of the total amount of all metal ions, fully stirred until completely dissolved; the temperature of the system is raised to 85 °C Stirring was continued until 83% of the water evaporated, at which point the solution gradually became viscous and formed a jelly. The jelly-like mass was dried in an oven at 200° C. for 48 hours and then ground in a mortar for 30 minutes. The obtained powder was heated up to 600°C at a rate of 10°C / min in a tube furnace and calcined at this temperature for 5 hours. After cooling, the powder was taken out and continued to grind in a mortar for 30 minutes, and the powder was pressed with a pressure of 300MPa. It was formed into a sheet, and then calcined in a tube furnace at a rate of 9°C / min to 950°C for 15 hours, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com