Color simulation method for digital proofing

A technology of digital proofing and simulation method, applied in the direction of image communication, electrical components, etc., can solve difficult, troublesome and complex problems, and achieve the effect of easy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

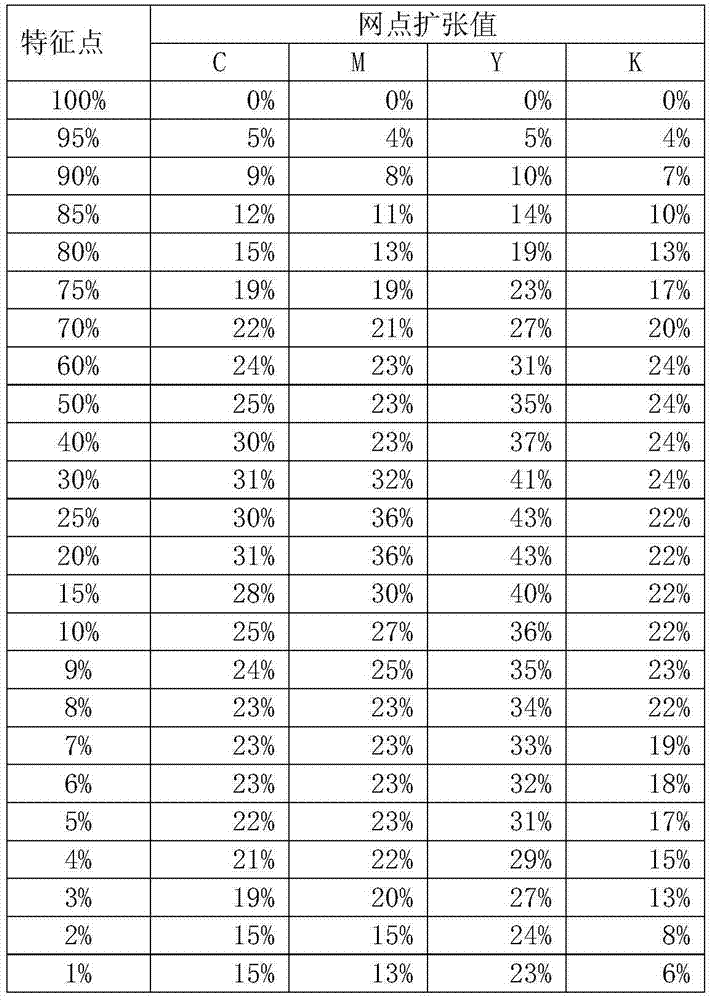

Embodiment 1

[0021] The color simulation method of digital proofing of the present invention, its concrete steps are as follows:

[0022] 1. The selected printing process type is satellite wide-format flexographic printing, and determine its specific printing process conditions:

[0023] Use comexi brand FPLUS 2510 flexographic printing machine, Flint FAH114D printing plate, sinwa company for laser plate making, printing plate 110 L / inch square dots, screen angle C: 67.5°, M: 37.5°, Y: 82.5°, K: 7.5°, the thickness of the tesa company is 0.5mm neutral hardness double-sided adhesive plate, using the FLX series alcohol-soluble ink of Hanghua Ink, the ink diluent uses ethanol: propylene glycol ether = 4: 1, printing viscosity 22s, printing The speed is 300m / min, the substrate is milky white PE-LD film, cyan (C) uses apex 315 (l / cm) anilox roll, magenta (M) uses apex 275 (l / cm) anilox roll, yellow (Y) use apex 200 (l / cm) anilox roll, black (K) use apex 400 (l / cm) anilox roll;

[0024] In add...

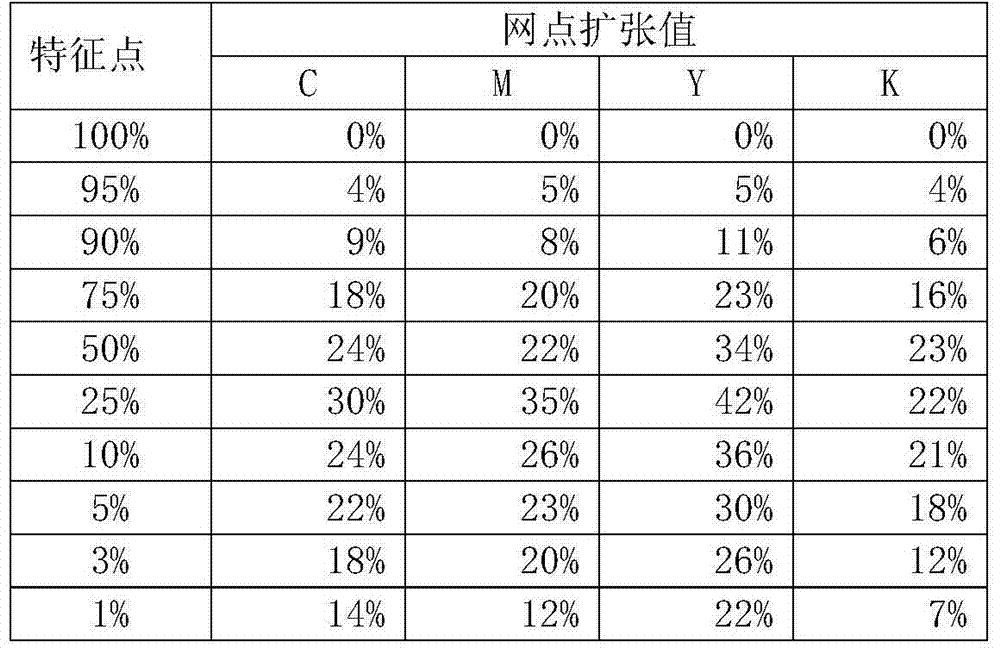

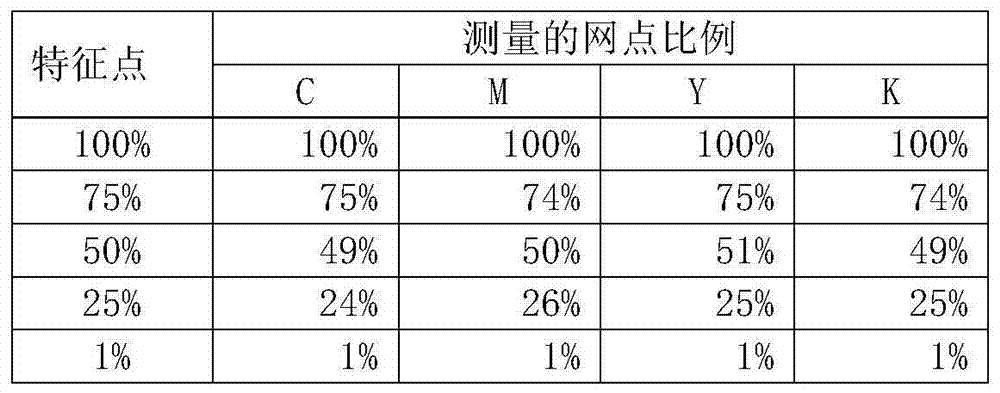

Embodiment 2

[0054] 1. The selected printing process type is satellite wide-format flexographic printing, and determine its specific printing process conditions:

[0055] Use the F10 gravure printing machine of FUJI brand, the circumference of the printing plate of Shanghai Yuncheng Plate is 510mm, the screening process is carried out according to Table 6, and the GC01 series ester-soluble ink of Letong Ink is used, and the ink diluent uses ethyl acetate: n-propyl acetate : Isopropanol=5:4:1, printing viscosity 15s, printing speed 180m / min, substrate is transparent PET shrink film.

[0056] Table 6, Screening process of various colors

[0057]

C

M

Y

K

special blue

Screening angle

30°

60°

45°

30°

30°

Screening lines

70L / cm

70L / cm

70L / cm

100L / cm

70L / cm

[0058] In addition, an Epson7910 digital printer was also selected and adjusted so that the printed products would not have dot expansion.

[0059...

Embodiment 3

[0087] The color simulation method implementation example 3 of digital proofing of the present invention, its concrete steps are as follows:

[0088] 1. Use the same printing conditions as in Embodiment 2.

[0089] 2. The same method as step 3 of the specific embodiment 2 is used to make an electronic file, which is composed of M+special green, the printing process of M is exactly the same as M in the specific embodiment 2, and the printing process of the special green is the same as that of the specific embodiment 2 special blue exactly the same;

[0090] 3. Known special green L * =46.27,a * =-74.66, b * =28.37, the color of M is exactly the same as the M of the specific embodiment 2, carry out the same steps 4, 5, 6 as the specific embodiment 2, and combine the CIE L of the two colors * ,a * ,b * Into step 6, you can get a satisfactory digital sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com