Interlayer film for laminated glass, and laminated glass

A technology of laminated glass and interlayer film, applied in glass/slag layered products, layered products, transportation and packaging, etc., can solve problems such as ghosting of measurement and test information, and achieve the effect of improving breakdown resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0133] Preparation of first and second surface layers:

[0134] Add 40 parts by weight of triethylene glycol di-2-ethylhexanoate (3GO) as a plasticizer to 100 parts by weight of polyvinyl butyral resin (PVB resin, 30 mol% of hydroxyl content), and mix The rollers were fully kneaded to prepare composition 1 for making the first and second surface layers.

[0135] The production of the middle layer:

[0136] Add 60 parts by weight of triethylene glycol di-2-ethylhexanoate (3GO) as a plasticizer to 100 parts by weight of polyvinyl butyral resin (PVB resin, hydroxyl content 25 mol%), use a mixing The rollers were sufficiently kneaded to prepare a composition 2 for producing an intermediate layer.

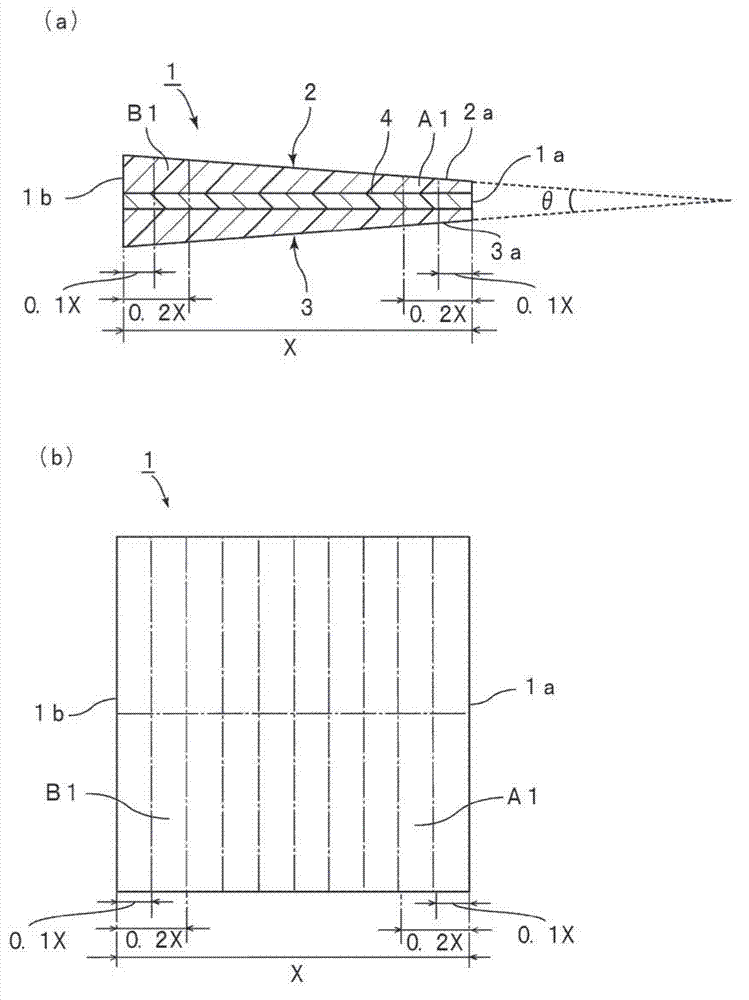

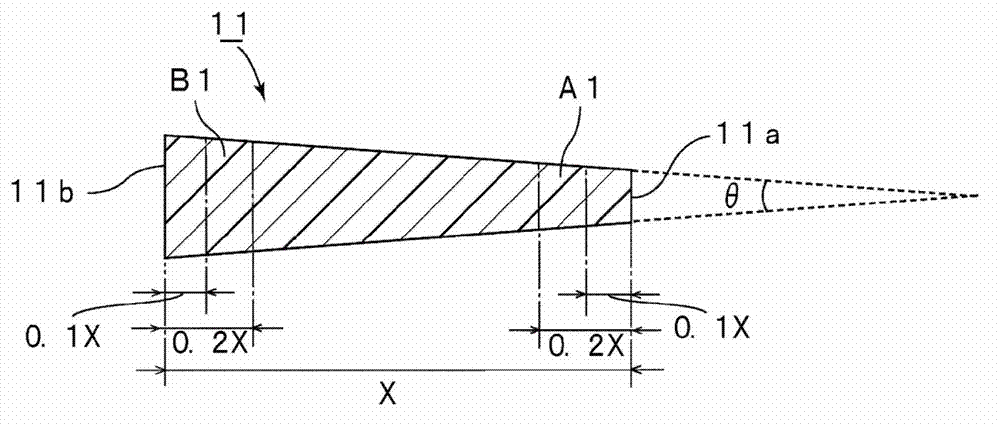

[0137] Production of multilayer interlayer film:

[0138] The obtained compositions 1 and 2 were coextruded using an extruder to obtain a laminate in which an intermediate layer was laminated between the first and second surface layers. Next, the obtained laminate was stored in a hi...

Embodiment 2~11

[0142] The amount of hydroxyl groups of the PVB resin, the type and content of the plasticizer, the cross-sectional shape in the thickness direction, the maximum thickness and the minimum thickness, and the wedge angle θ are set as shown in Table 1 below. Similarly, a multilayer interlayer film and laminated glass were obtained.

Embodiment 12

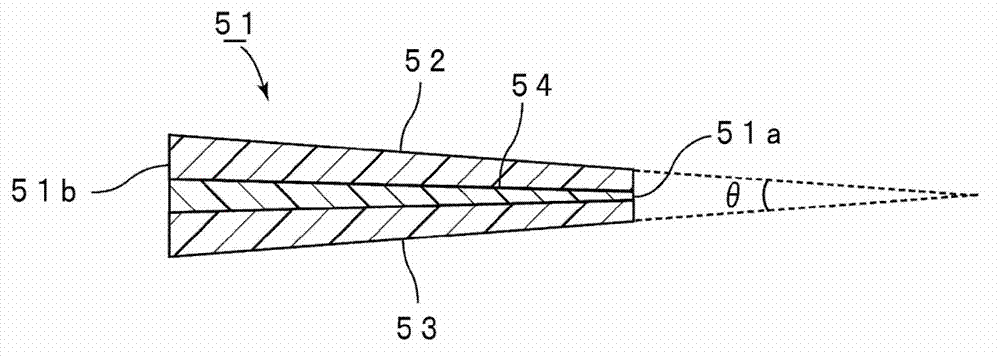

[0144] Production of single-layer interlayer film:

[0145]Add 40 parts by weight of triethylene glycol di-2-ethylhexanoate (3GO) as a plasticizer to 100 parts by weight of polyvinyl butyral resin (PVB resin, 30 mol% of hydroxyl content), and mix After sufficient kneading by the rollers, extrusion molding is performed using an extruder to produce a molded body. A single-layer interlayer film (length 1000mm) was prepared by storing the obtained molded article in an environment with high temperature and high humidity or with local differences in temperature and humidity in an environment with high temperature and low humidity to locally change the moisture content. × horizontal 350mm). For this single-layer interlayer film, the thickness of one end in the longitudinal direction is thinner than the thickness of the other end opposite to the one end, and the thickness in the transverse direction is uniform, and the maximum thickness and minimum thickness of the interlayer film ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com