Nano-cellulose modified low-conductivity olive insulating oil and preparation method thereof

A nano-cellulose, low-conductivity technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of easy aging of olive insulating oil, transformer insulation failure, insulation performance decline, etc., to facilitate popularization and industrial production, and reduce electrical conductivity The effect of low current and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Preparation of Nanocellulose Modified Low Conductivity Olive Insulating Oil

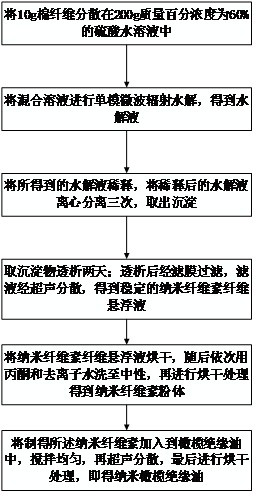

[0032] The preparation process of nanocellulose-modified low-conductivity olive insulating oil is as follows figure 1 shown, as follows:

[0033] S1. Preparation of nanocellulose particles:

[0034] S1.1. 10g cotton fibers are dispersed in 200g mass percent concentration of sulfuric acid aqueous solution of 60%;

[0035] S1.2. The mixed solution is hydrolyzed by single-mode microwave radiation to obtain a hydrolyzed solution; wherein the temperature of the hydrolysis process is 45°C, the single-mode microwave radiation power is 100 W, and the radiation time is 5 minutes.

[0036] S1.3. the obtained hydrolyzate is diluted to 10 times of the original hydrolyzate volume, and the diluted hydrolyzate is centrifuged three times under the condition of 10000rpm rotating speed, and the precipitation is taken out;

[0037] S1.4. Take the precipitate for dialysis for two days, filter throug...

Embodiment 2

[0042] S1. Preparation of nanocellulose particles:

[0043] S1.1. 9.5g cotton fibers are dispersed in 200g mass percent concentration of sulfuric acid aqueous solution of 60%;

[0044] S1.2. The mixed solution is subjected to single-mode microwave radiation hydrolysis to obtain a hydrolyzed solution; wherein the hydrolysis process temperature is 45°C, the single-mode microwave radiation power is 100 W, and the radiation time is 6 minutes.

[0045] S1.3. the obtained hydrolyzate is diluted to 10 times of the original hydrolyzate volume, and the diluted hydrolyzate is centrifuged three times under the condition of 10000rpm rotating speed, and the precipitation is taken out;

[0046] S1.4. Take the precipitate for dialysis for two days, filter through a filter membrane after dialysis, and disperse the filtrate by ultrasonic to obtain a stable nanocellulose fiber suspension; wherein the molecular weight cut-off of the dialysis membrane used is more than 8000, and the pore size of ...

Embodiment 3

[0051] S1. Preparation of nanocellulose particles:

[0052] S1.1. Disperse 10.5g cotton fiber in 210g mass percent concentration of sulfuric acid aqueous solution of 60%;

[0053]S1.2. The mixed solution is subjected to single-mode microwave radiation hydrolysis to obtain a hydrolyzed solution; wherein the hydrolysis process temperature is 47°C, the single-mode microwave radiation power is 100 W, and the radiation time is 5 minutes.

[0054] S1.3. the obtained hydrolyzate is diluted to 10 times of the original hydrolyzate volume, and the diluted hydrolyzate is centrifuged three times under the condition of 10000rpm rotating speed, and the precipitation is taken out;

[0055] S1.4. Take the precipitate for dialysis for two days, filter through a filter membrane after dialysis, and disperse the filtrate by ultrasonic to obtain a stable nanocellulose fiber suspension; wherein the molecular weight cut-off of the dialysis membrane used is more than 8000, and the pore size of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com