System and method for producing fuels from biomass/plastic mixtures

A biomass and mixture technology, which is applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, fuels, etc., can solve the problems of complexity and laborious system control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

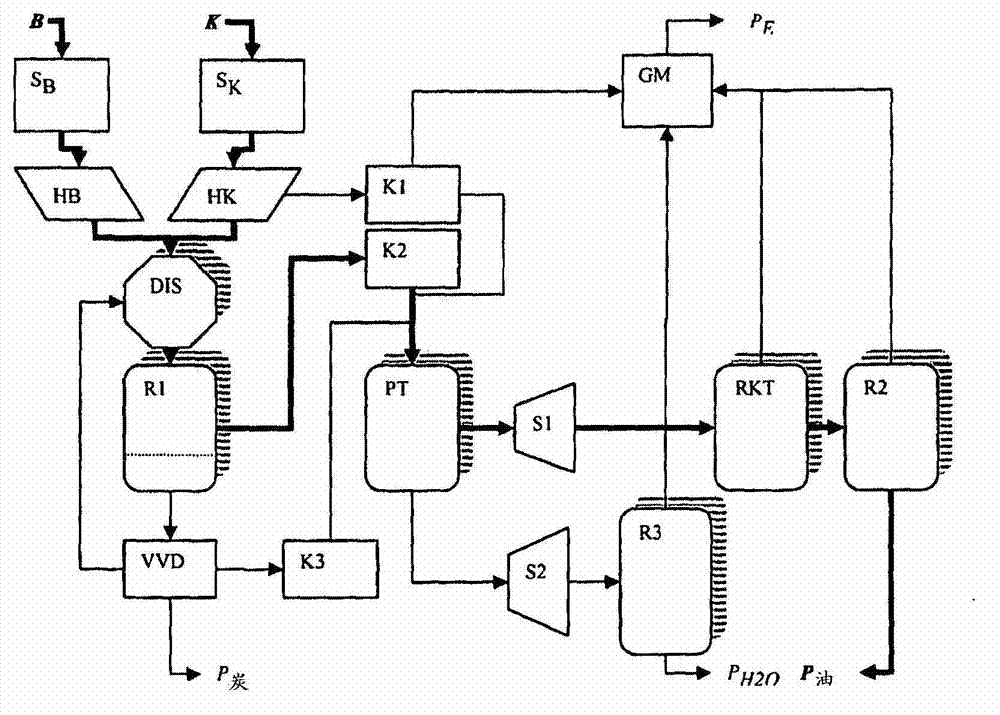

[0166] according to figure 1 , raw materials of biological origin and plastics are supplied continuously in two parallel paths via silos and heating screws to the disperser and from there directly to the reactor. No catalyst was added. Do not add carrier oil after system start-up.

[0167] From the tests carried out the following balance was obtained:

[0168] Mass balance: 800 kg of dry biomass + 200 kg of dry mixed plastic yields 300 kg of product oil, equivalent to 360 liters of product oil (17.5% yield of biosource, 80% yield of plastic, product oil density 0.833kg / L). There is no need to add additional carrier oil, because the oil production method of the present invention is balanced. The difference to 1000 kg consists of the effluent of gas, product water and char.

[0169] Energy balance: 800kg×5kWh / kg+200kg×12kWh / kg6400kWh input calorific value; 360L×10kWh / L=3600kWh output oil calorific value; 3600kWh / 6400kWh=56.3% energy yield. The energy difference compared to ...

Embodiment 2

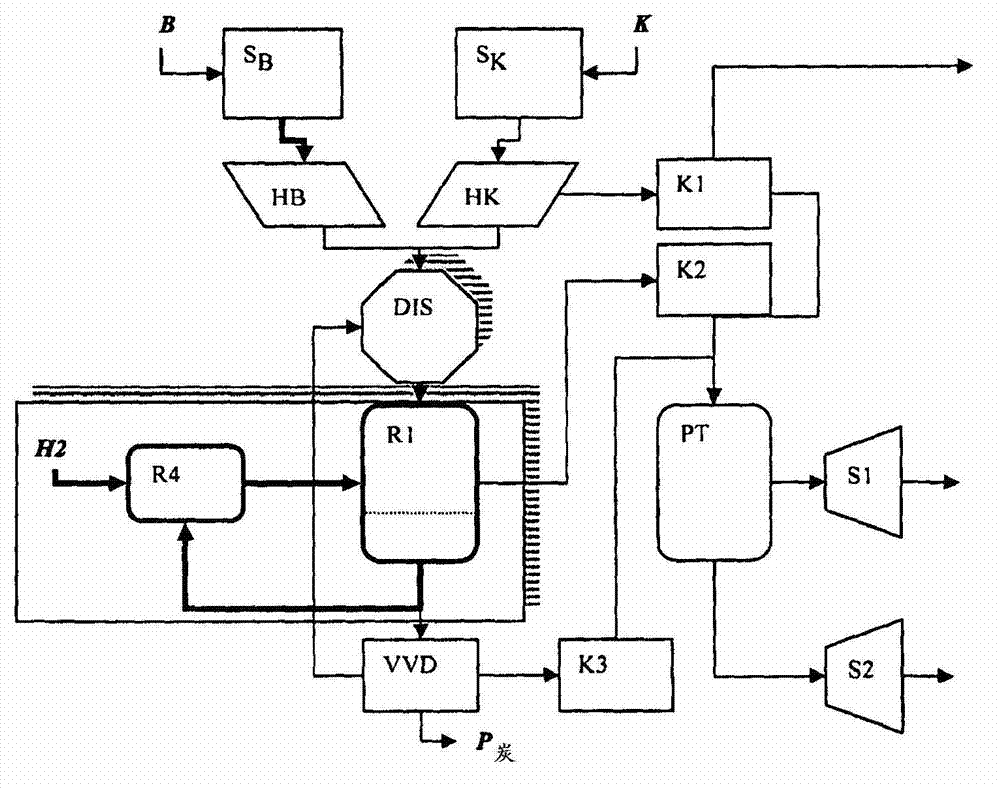

[0171] according to figure 2 , raw materials of biological origin and plastics are supplied continuously in two parallel paths via silos and heating screws to the disperser and from there directly to the reactor. No catalyst was added (neither in R1 nor R4). Do not continue to add carrier oil after system start-up.

[0172] The bottom phase is continuously withdrawn from R1 (100-1000 L / h; solid consistency: 5-20% by mass, temperature: 50-380 °C) and hydrogenated in R4 at a positive pressure of 0-10 bar (ultrasonic parameters: frequency: 18 -30kHz, power parameters: 300-3000W / L). The resulting reaction product is recycled to reactor R1.

[0173] According to the tests carried out, the formation of char was reduced compared to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com