Brown stain resistant, preservative and fresh-keeping technology of fresh wet noodles

An anti-browning, fresh and wet noodle technology, applied in food preservation, dough processing, food science and other directions, can solve problems such as spoilage and deterioration, affecting the factory production and commercial sales of fresh and wet noodles, and noodle spoilage and so on. , to overcome the easy browning and mildew deterioration, change the effect of poor preservation, and improve the shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

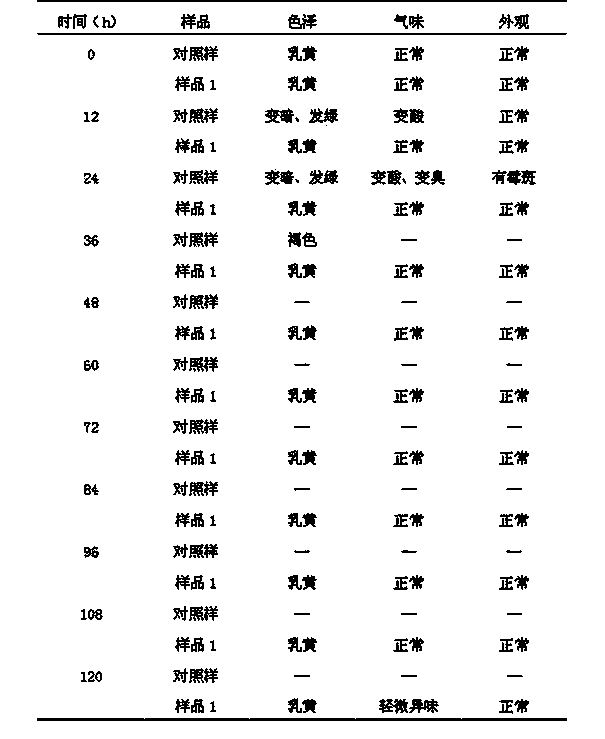

Embodiment 1

[0018] Production of sample 1: Add 3g of kojic acid, 3g of EDTA, 0.1g of polylysine, and 40g of ethanol to 300g of water to dissolve, then add it to 1000g of flour, knead fast for 4 minutes, slow knead for 1 minute, and stop kneading. Finally, let the flour wadding stand for 20 minutes to mature. After curing, it will be rolled by a noodle press, and then cut into strips after 7 steps of calendering. Put the noodles into a plastic tray, put a bag of deoxidizer with an oxygen absorption capacity of 1800ml / bag at the bottom of the tray, and use an oxygen permeability rate of 10ml / (m 2 ·24h·0.1MPa), 25°C (hereinafter referred to as the oxygen permeability rate of 10), composite material packaging and sealing bag, the length and width of the bag are 30cm*20cm. Pack into 300g of noodles to form the final product.

[0019] Production of the control sample: add 300g of water to 1000g of flour, knead quickly in the dough mixer for 4 minutes, slow knead for 1 minute, stop kneading and...

Embodiment 2

[0025] Production of sample 2: Add 6 g of kojic acid, 1 g of EDTA, 0.4 g of polylysine, and 10 g of ethanol to 300 g of water to dissolve completely, then add it to 1000 g of flour, knead fast for 4 min in the dough mixer, knead slowly for 1 min, stop mixing After making noodles, let the flour wadding stand and mature for 20 minutes. After curing, it will be rolled by a noodle press, and then cut into strips after 7 steps of rolling. Put the noodles into a plastic tray, put a bag of deoxidizer with an oxygen absorption capacity of 600ml / bag at the bottom of the tray, and use a composite material packaging bag with an oxygen permeability rate of 100. The length and width of the bag are 30cm*20cm. Pack into 300g of noodles to form the final product.

[0026] Sample 2 and the control sample were stored at 30°C, and the color, smell and appearance of the noodles were regularly observed and recorded. The results are shown in Table 2.

[0027] Table 2

[0028]

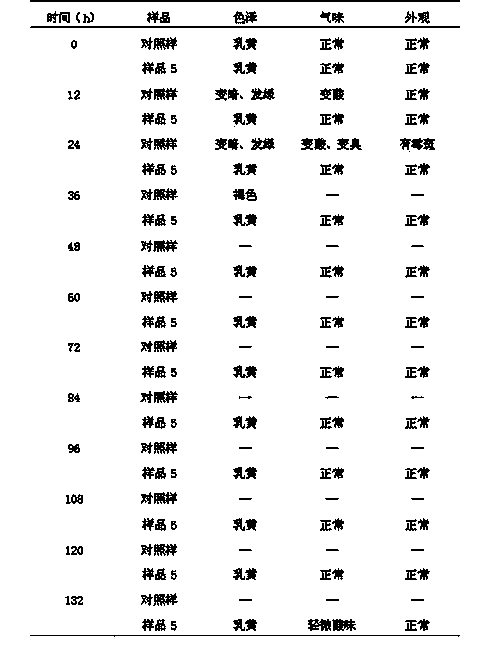

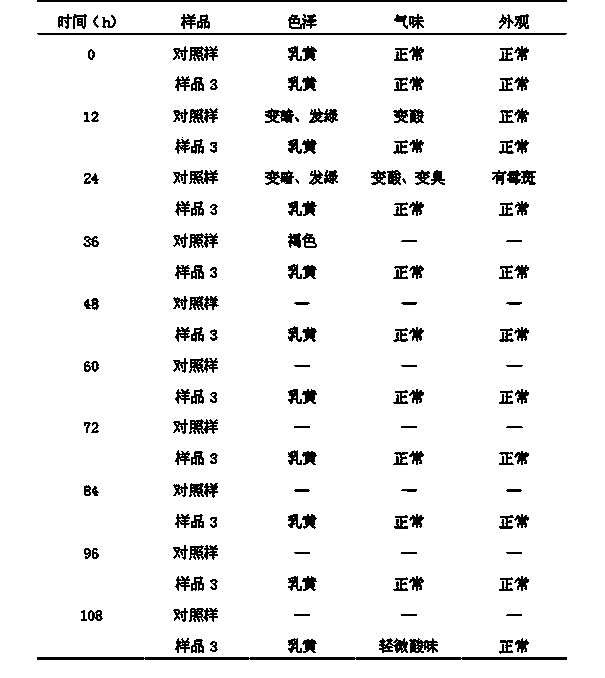

Embodiment 3

[0030] Sample 3: Dissolve 4g of kojic acid, 2g of EDTA, 0.25g of polylysine, and 20g of ethanol in 300g of water, then add it to 1000g of flour, knead fast for 4 minutes and slow for 1 minute, then stop kneading Finally, let the flour wadding stand for 20 minutes to mature. After curing, it will be rolled by a noodle press, and then cut into strips after 7 steps of calendering. Put the noodles into a plastic tray, put a bag of deoxidizer with an oxygen absorption capacity of 600ml / bag at the bottom of the tray, and use a composite material packaging bag with an oxygen permeability rate of 50. The length and width of the bag are 30cm*20cm. Pack into 300g of noodles to form the final product.

[0031] Sample 3 and the control sample were stored at 30°C, and the color, smell and appearance of the noodles were regularly observed and recorded. The results are shown in Table 3.

[0032] table 3

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com