Preparation method of whole egg powder with high gelation and high gel stability

A high-gelling, whole egg powder technology, applied in the field of food chemical processing, can solve the problem that the nutritional comprehensiveness of whole egg powder cannot be fully utilized and exerted, and there is no improvement in the gelation of whole egg liquid, which affects the application of whole egg powder range and other issues, to achieve the effect of shortening the modification reaction time, good solubility and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

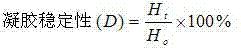

Image

Examples

Embodiment 1

[0031] A preparation method of whole egg powder with high gel property and high gel stability, characterized in that it is prepared according to the following steps:

[0032] (1) Select fresh eggs, remove the shells to obtain whole egg liquid, stir the whole egg liquid at a speed of 15-20rpm slowly and evenly, filter to obtain uniform whole egg liquid, and set aside;

[0033] (2) Take monosaccharides and polysaccharides at a mass ratio of 3:1, mix them with water at 50°C to obtain a complex sugar solution with a mass percentage concentration of 0.8%, and combine the complex sugar solution with a mass percentage concentration of 0.8% with step (1) The obtained whole egg liquid is uniformly mixed according to a mass ratio of 1:1, and the pH value is adjusted to 6.2 to obtain a mixed solution;

[0034] (3) Put the mixed solution in a storage tank, first react at a temperature of 53°C for 30 minutes, then react at a temperature of 78°C for 30 minutes, and control the relative humi...

Embodiment 2

[0039] A preparation method of whole egg powder with high gel property and high gel stability, characterized in that it is prepared according to the following steps:

[0040] (1) Select fresh eggs, remove the shells to obtain whole egg liquid, stir the whole egg liquid at a speed of 15-20rpm slowly and evenly, filter to obtain uniform whole egg liquid, and set aside;

[0041] (2) Take monosaccharides and polysaccharides at a mass ratio of 3:1, mix them with water at 46°C to obtain a complex sugar solution with a mass percentage concentration of 0.2%, and combine the complex sugar solution with a mass percentage concentration of 0.2% with step (1) The obtained whole egg liquid is uniformly mixed according to a mass ratio of 1:1, and the pH value is adjusted to 6.2 to obtain a mixed solution;

[0042] (3) Put the mixed solution in a storage tank, first react at a temperature of 52°C for 15 minutes, then react at a temperature of 76°C for 30 minutes, and control the relative humidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com