Suspension extrusion fiber filter

A fiber filter and filter technology, which is applied in the directions of gravity filter, loose filter material filter, filtration and separation, etc., can solve the problems of cumbersome operation, high use cost, poor adsorption effect, etc., and achieve strong adsorption and interception ability. , The effect of high water output precision and strong adsorption force

Inactive Publication Date: 2013-05-08

扬州绿都环境工程设备有限公司

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, industrial production often produces a large amount of sewage, which cannot be discharged directly, otherwise it will pollute the environment. However, most of the existing sewage treatment devices have complex structures, cumbersome operations, high use costs, poor adsorption effects, and uneven adsorption of pollutants. The accuracy of the water outlet is poor, which cannot meet the production needs of the enterprise

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

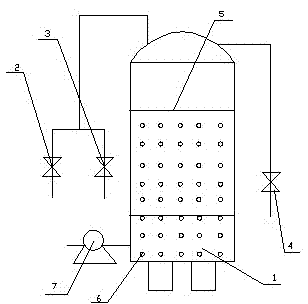

[0008] A suspended extruded fiber filter, comprising a filter tank body 1, a water inlet valve 2, a backwash water inlet valve 3 and a backwash water outlet valve 4, the filter tank body 1 is provided with two layers of filter layers 5 The filter medium is evenly distributed in the filter tank body 1, and the filter medium is a fiber filament 6, and a hydraulic transmission device 7 is connected outside the filter tank body 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a suspension extrusion fiber filter, which comprises a filter tank body, a water inlet valve, a backwashing water inlet valve and a backwashing water outlet valve, wherein two filtration layers are arranged inside the filter tank body, a filtration medium is uniformly distributed in the filter tank body and is fibers, and a hydraulic transmission device is connected outside the filter tank body. The suspension extrusion fiber filter has advantages of simple structure, easy use, corrosion resistance, abrasion resistance, temperature resistance, long service life, strong adsorption and the like, wherein the fibers are uniformly distributed in the filter tank body, and the required work filtration layer is achieved through lifting by using the hydraulic transmission device, such that operation is convenient, targeted decontamination can be achieved, absorption and sewage interception capability is strong, and effluent precision is high.

Description

technical field [0001] The invention relates to a sewage filter, in particular to a suspended extruded fiber filter. Background technique [0002] At present, industrial production often produces a large amount of sewage, which cannot be discharged directly, otherwise it will pollute the environment. However, most of the existing sewage treatment devices have complex structures, cumbersome operations, high use costs, poor adsorption effects, and uneven adsorption of pollutants. The accuracy of the water outlet is poor, which cannot meet the production needs of the enterprise. Contents of the invention [0003] In order to solve the above problems, the present invention provides a hanging extruded fiber filter with simple structure, good adsorption effect and high water outlet precision. [0004] The technical solution of the present invention is: comprising a filter tank body, a water inlet valve, a backwash water inlet valve and a backwash water outlet valve, the filter ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D24/10

Inventor 张有庆任连锁

Owner 扬州绿都环境工程设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com