Producing method of snap spring

A production method and circlip technology, applied in the field of construction machinery, can solve the problems of high investment in personnel and equipment, complex production process of circlips, unsuitable for mass production, etc., to avoid manual operation, easy quality control, and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

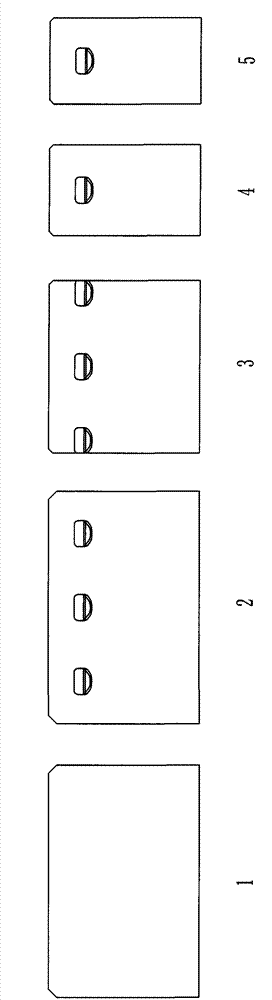

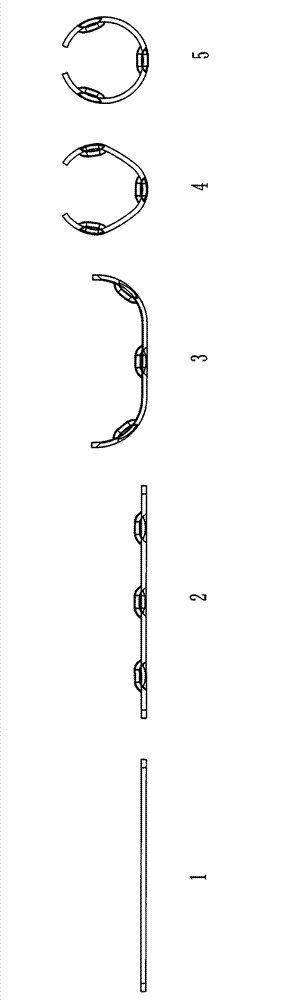

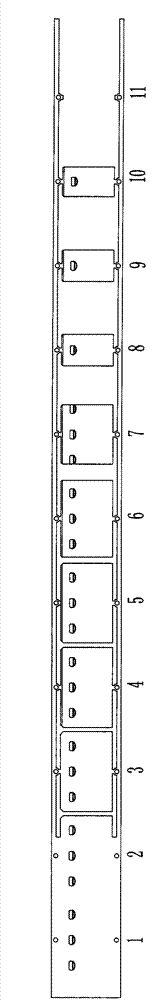

[0028] The following further describes the embodiments of the present invention with reference to the accompanying drawings:

[0029] The present invention is a method for producing a circlip, which includes the following steps:

[0030] a. Cutting: Cut the steel coil of the required thickness into steel strips according to the required width. The width of the steel strip is larger than the width of the circlip, so that the width of the steel strip is larger than the width of the circlip, which can be convenient in one-time Automatic continuous operation of the forming process;

[0031] b. Feeding: Load the steel plate into the automatic feeder, and send one end of the steel belt into the progressive die installed on the hydraulic punch through the feeder; the feeding frequency of the feeder is the same as the punching frequency of the hydraulic punch and the feeding length The length of the station is the same as that of the progressive die. When the feeder feeds the steel belt int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com