Waste wood dust isolating device used for sheet cutting device

A cutting device, isolation device technology, applied in wood processing appliances, bark area/debris/dust/waste removal, manufacturing tools, etc., can solve problems such as worker injury, worker working environment pollution, ejection, etc., to protect health , Prevent entering the human eye, prevent the effect of reversal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

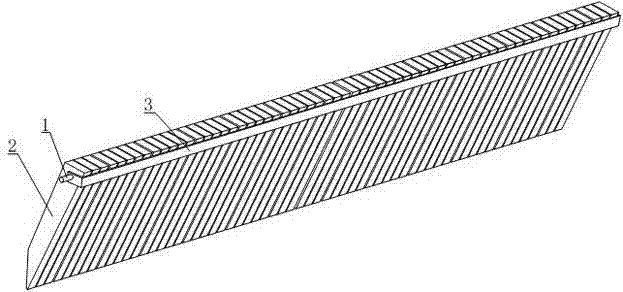

[0018] Such as figure 1 Therefore, the present invention is used in the waste debris isolation device of the plate cutting device. The hanging rod 1 is hung with a plurality of baffles 2, and the baffles 2 are in the shape of a sheet with a small bottom and a large top, and its thickness is very small, and , the area of the bottom of the baffle 2 is smaller than the area of the top of the baffle 2, and a plurality of gaskets are set on the hanging rod 1, and there is a gasket between any two baffles 2, and the aperture of the gasket is larger than the diameter of the hanging rod 1. The aperture on the sheet 2 is larger than the diameter of the hanging rod 1, and the anti-backward plate 3 is fixedly connected to the hanging rod 1. The axis of the anti-backward plate 3 is parallel to the axis of the hanging rod 1, and the distance between the anti-backward plate 3 and the hanging rod The distance is greater than the distance between the top of the blocking plate 2 and the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com