Method for removing sulfur components in petroleum coke through using sodium hydroxide/potassium carbonate melting process

A technology of potassium hydroxide and sodium hydroxide, which is applied in the field of sodium hydroxide/potassium fusion to remove sulfur components in petroleum coke and remove harmful elements, and can solve the problems of incomplete desulfurization of petroleum coke, high cost of comprehensive assembly, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

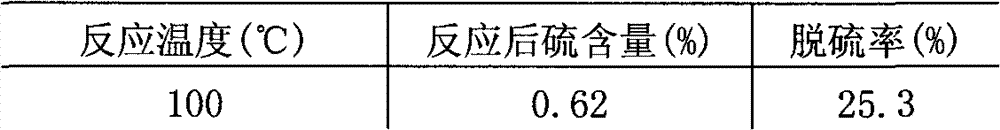

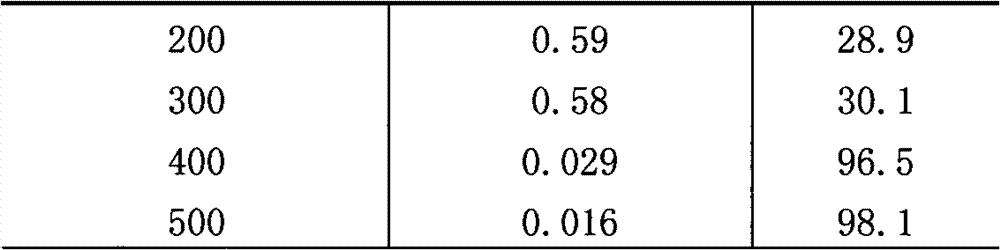

[0026] Take 10 grams of petroleum coke, add the amount of alkali according to the alkali / coke mass ratio of 1:12, and mix well. Calcined in a muffle furnace at 450°C for 2 hours, cooled, dissolved in water, filtered and washed, and dried to measure the sulfur content, the sulfur removal rate was 27.7%.

Embodiment 2

[0028] The mass ratio of alkali / coke is 1:6, the others are the same as [006], and the sulfur removal rate reaches 32.5%.

Embodiment 3

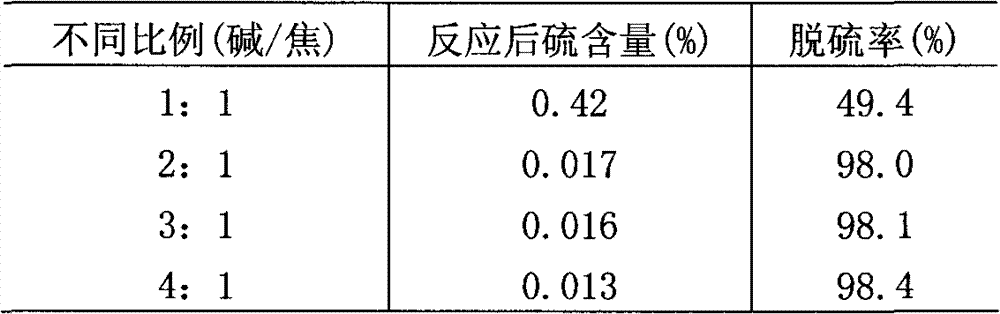

[0030] The mass ratio of alkali / coke is 2:1, and the others are the same as [006]. The sulfur removal rate reaches 98.4%, and the sulfur content in the product is less than 0.1%, which meets the standard of first-grade coke.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com