Thermal insulation and heat preservation slurry composition and thermal insulation and heat preservation plate containing the same

A technology of heat insulation and composition, applied in the direction of heat preservation, building structure, building components, etc., can solve the problems of easy pulverization, unstable shape, broken files, etc., and achieve the effect of excellent heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

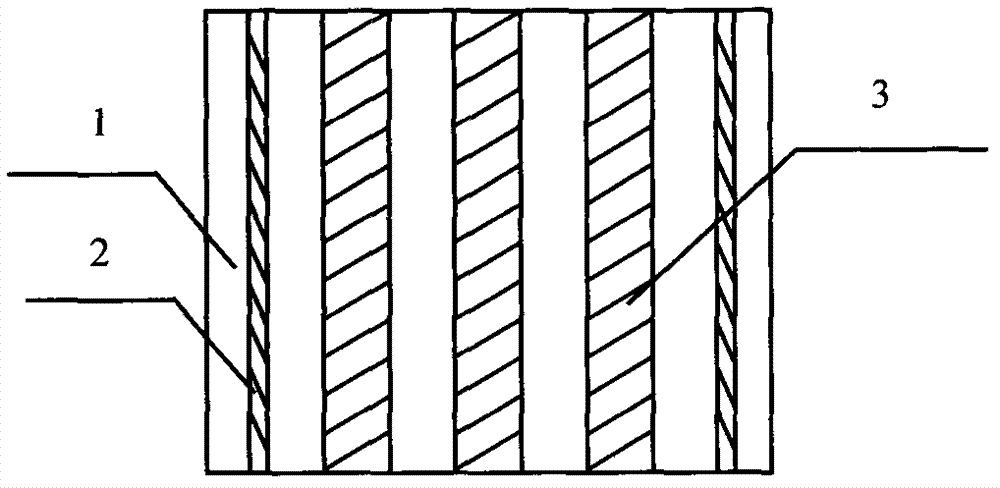

[0032] The thermal insulation composite board provided by the present invention is usually formed by applying a layer of thermal insulation slurry layer on the two outer surfaces of one or more layers of thermal insulation material layers stacked together; In the embodiment, it is also possible to apply a layer of thermal insulation slurry between these layers of thermal insulation material layers stacked together to improve the strength and / or flame retardancy of the board; in a better implementation In the scheme, it is even more possible to place glass fiber mesh cloth in the heat insulation slurry layer applied on the two outer sides of the heat insulation material layer to increase the strength of the board, as shown in the attached figure 1 As shown: the thermal insulation board adopts a multi-layer (three-layer) thermal insulation sheet 3 stacking method, and these layers of thermal insulation sheets 3 are filled with a thermal insulation slurry layer 1, and at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com