Preparation method of aqueous-solution-method-modified starch rubber functional auxiliary agent

The technology of an aqueous solution method and a functional additive is applied in the field of preparation of an aqueous solution modified starch rubber functional additive, which can solve the problems of damage, high heat generation, low elasticity, etc., and achieves simple process, low dynamic temperature rise, and fatigue resistance. good effect

Inactive Publication Date: 2013-05-08

SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, because carbon black will cause serious damage to the surrounding environment during the production process, and at the same time, the vulcanized rubber obtained by carbon black as a rubber reinforcing agent has problems such as high heat generation and low elasticity. Therefore, people have been looking for a supplement Strong agent instead of carbon black

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings.

[0018] Application examples

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Login to View More

Abstract

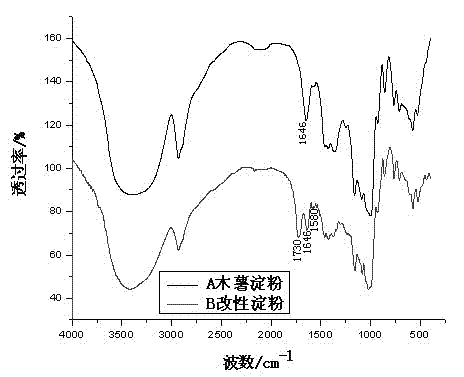

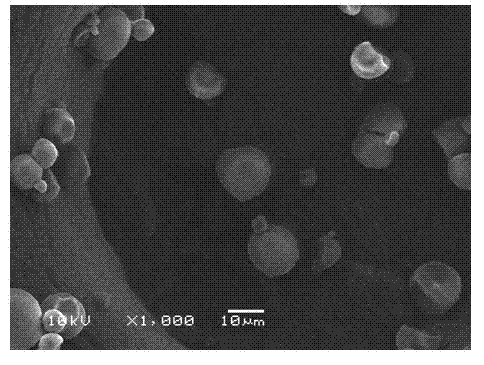

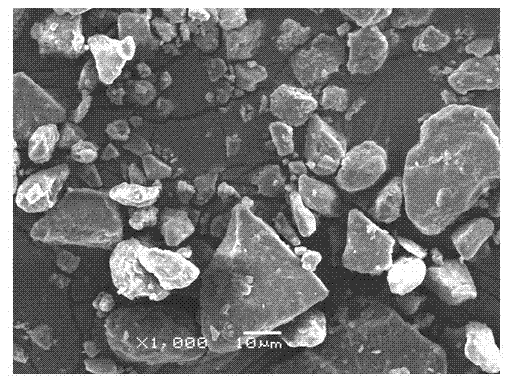

The invention relates to a preparation method of an aqueous-solution-method-modified starch rubber functional auxiliary agent, and relates to a preparation method of a rubber auxiliary agent. The method comprises the steps that: under a condition of mechanical stirring, corn starch or tapioca starch is gelatinized with added distilled water; a component A is added under a temperature of 70-100 DEG C, wherein the component A is one or a combination of proton acid or aluminum salt such as aluminum nitrate, aluminum phosphate, hydrochloric acid, sulfuric acid, nitric acid, and benzoic acid; a component B is simultaneously added, wherein the component B is alkenyl acid or anhydride containing c=c double bond, such as maleic anhydride or acrylic acid; a reaction is carried out for 0.5-4h; a reaction product is bake-dried, such that a starch derivative is prepared. The mass ratio of the component A to starch is 1:5-1:100, and the mass ratio of the component B to starch is 1:5-1:100. The filling material provided by the invention has the advantages of simple production process, low cost, and high environment-protection degree. The product is widely applied in various tires and other rubber products.

Description

technical field [0001] The invention relates to a preparation method of a rubber auxiliary agent, in particular to a preparation method of an aqueous solution method modified starch rubber functional auxiliary agent. Background technique [0002] In the rubber industry, traditional rubber reinforcing agents are mainly based on carbon black fillers. However, because carbon black will cause serious damage to the surrounding environment during the production process, and at the same time, the vulcanized rubber obtained by carbon black as a rubber reinforcing agent has problems such as high heat generation and low elasticity. Therefore, people have been looking for a supplement Strong agent instead of carbon black. In recent years, with the implementation of EU labeling regulations, strict requirements have been imposed on the rolling resistance of tires and additive pollution, and newer development topics for functionalized rubber additives need to be proposed. Starch is a ki...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08B31/04C08L9/00C08L9/06C08L3/06

Inventor 方庆红刘文

Owner SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com