Liquid polyisoprene, preparation method and application thereof

A technology of polyisoprene and isoprene, which is applied in the field of liquid polyisoprene and its preparation and application, can solve the problems of unfavorable health of operators, cumbersome operation, unfavorable environmental protection, etc., and achieve easy operation And environmental protection, narrow molecular weight distribution, and the effect of improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

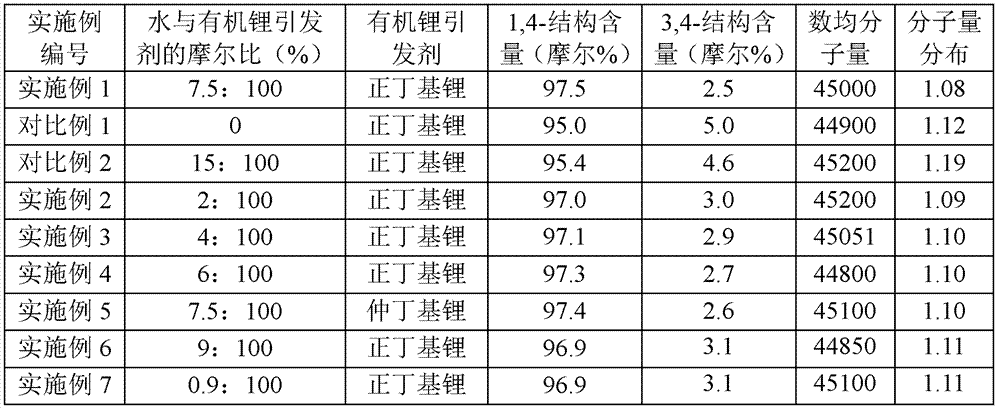

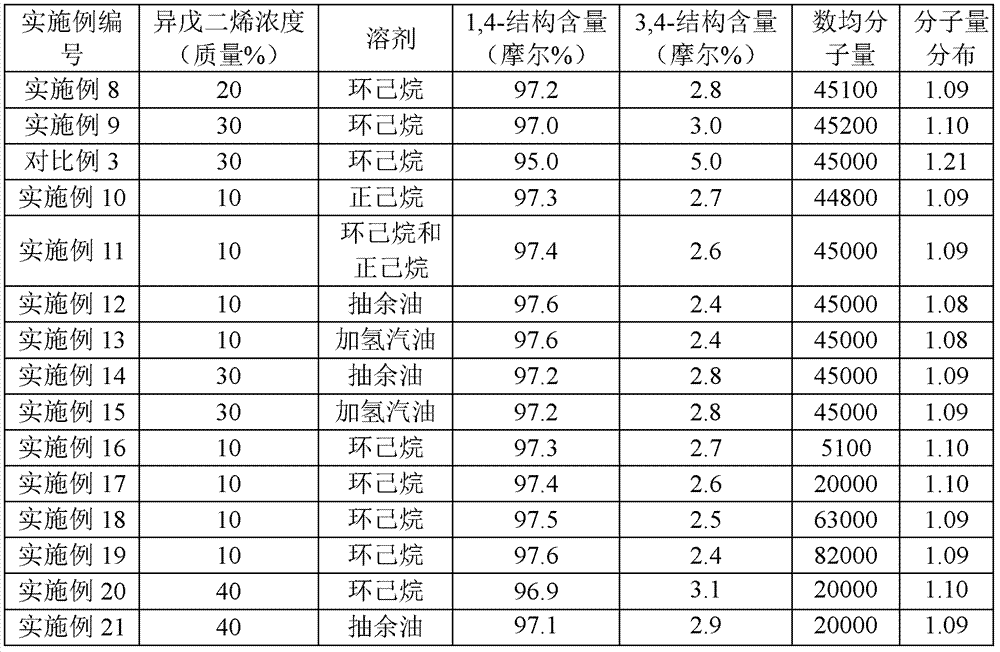

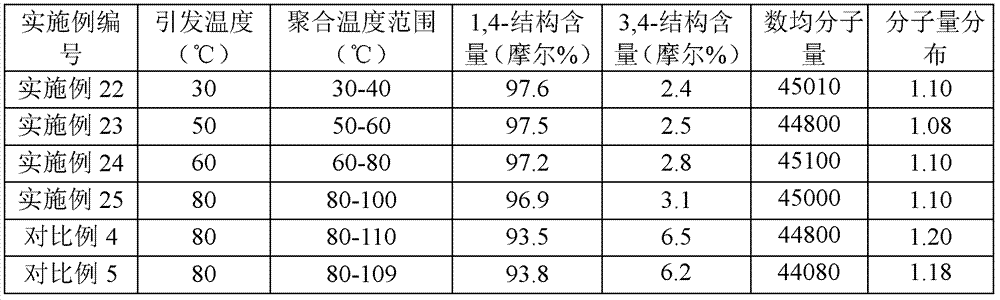

[0018] The invention provides a method for preparing liquid polyisoprene, the method comprising: under anionic polymerization conditions, contacting isoprene with an organolithium initiator and water in a solvent; wherein, water and the The molar ratio of the organic lithium initiator is 0.9-9:100.

[0019] According to the method of the present invention, the molar ratio of water to the organolithium initiator is 0.9-9:100. When the molar ratio of water to the organolithium initiator is within the above range, the molecular weight distribution of the finally obtained polyisoprene can reach below 1.10, and in the obtained polyisoprene, isoprene is The content of the structural unit formed by 1,4-polymerization is high, which can reach more than 96.9 mole % (under the preferred condition, it can reach more than 97 mole %). And, since the molar ratio of water to the organolithium initiator is only 0.9-9:100, therefore, in theory, based on 100 moles of the organolithium initiato...

Embodiment 1

[0051] This example is used to illustrate the liquid isoprene and its preparation method and application according to the present invention.

[0052] Polymerization was carried out in a 5L polymerization reactor. After the polymerization system is replaced by high-purity nitrogen, 200g of isoprene monomer and 1800g of dry cyclohexane are added to the polymerization reactor in sequence, and deionized water is added to the polymerization reactor under stirring, and the stirring is continued for about 10 minutes and heated to 40°C, and then add 15.8mL of n-butyllithium n-hexane solution with a concentration of 0.3M at this temperature to start the polymerization reaction. During the polymerization reaction, the temperature is controlled within the range of 40-50°C, and the polymerization reaction The pressure in the kettle was controlled to be 0.1-0.3 MPa (gauge pressure), and the polymerization was carried out for 120 minutes. Wherein, the molar percentage of deionized water an...

Embodiment 2

[0058] This example is used to illustrate the liquid isoprene and its preparation method and application according to the present invention.

[0059] The same method as in Example 1 was used to polymerize isoprene, except that the molar ratio of deionized water to organolithium initiator was 2:100. The conversion of isoprene was 100%, as determined by weighing method. The prepared liquid polyisoprene was characterized and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com