Waste printed circuit board non-metal powder/ABS rein composite material and its preparation method

A technology of ABS resin and printed circuit board, applied in the direction of coating, etc., to achieve the effects of reducing production costs, protecting the environment, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

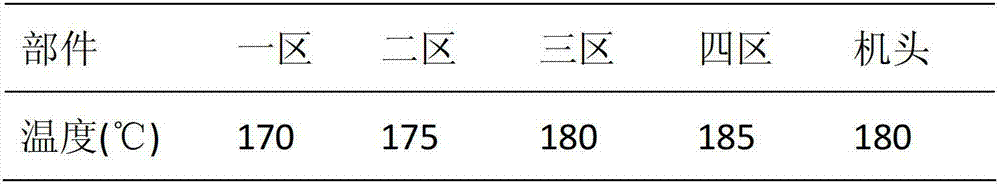

Embodiment 1

[0023] Waste printed circuit board non-metal powder / ABS resin composite material, including 200 mesh printed circuit board non-metal powder after the crushing and sorting of printed circuit boards, ABS resin, silane coupling agent KH-560 and composite processing aids, printed circuit boards The weight ratio of non-metal powder to ABS resin is 10:90, silane coupling agent KH-560 accounts for 0.8wt% of non-metal powder in printed circuit boards, mixed raw materials composed of composite processing aids, modified non-metal powder and ABS resin The mass ratio is 2.6:97.4;

[0024] The composite processing aid consists of 5wt% of sodium stearate, 15wt% of zinc stearate, 35wt% of liquid paraffin, 20wt% of antioxidant 1010, and 25wt% of antioxidant DLTP. composition.

[0025] The preparation method of waste printed circuit board non-metal powder / ABS resin composite material includes the following steps:

[0026] Step 1. Material pretreatment:

[0027] Mix the silane coupling agent KH-560 w...

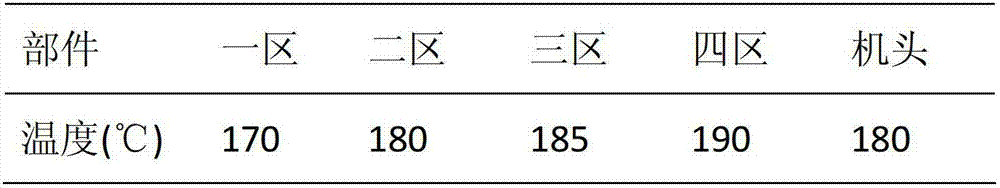

Embodiment 2

[0038] Waste printed circuit board non-metal powder / ABS resin composite material, including 200 mesh printed circuit board non-metal powder after the crushing and sorting of printed circuit boards, ABS resin, silane coupling agent KH-560 and composite processing aids, printed circuit boards The weight ratio of non-metal powder to ABS resin is 20:80, silane coupling agent KH-560 accounts for 1.0wt% of non-metal powder in printed circuit boards, and a mixed raw material composed of composite processing aids, modified non-metal powder and ABS resin The mass ratio is 2.6:97.4;

[0039] The composite processing aid is composed of 10wt% of sodium stearate, 15wt% of zinc stearate, 35wt% of liquid paraffin, 20wt% of antioxidant 1010, and 20wt% of antioxidant DLTP. composition.

[0040] The preparation method of waste printed circuit board non-metal powder / ABS resin composite material includes the following steps:

[0041] Step 1. Material pretreatment:

[0042] Mix silane coupling agent KH-...

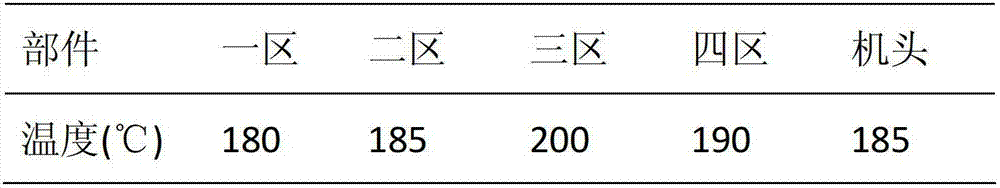

Embodiment 3

[0053] Waste printed circuit board non-metal powder / ABS resin composite material, including 200 mesh printed circuit board non-metal powder after the crushing and sorting of printed circuit boards, ABS resin, silane coupling agent KH-560 and composite processing aids, printed circuit boards The weight ratio of non-metal powder to ABS resin is 30:70, silane coupling agent KH-560 accounts for 1.2wt% of non-metal powder in printed circuit boards, mixed raw materials composed of composite processing aids, modified non-metal powder and ABS resin The mass ratio is 2.6:97.4;

[0054] The composite processing aid is composed of 15% by weight of sodium stearate, 15% by weight of zinc stearate, 20% by weight of liquid paraffin, 25% by weight of antioxidant 1010, and 25% by weight of antioxidant DLTP. composition.

[0055] The preparation method of waste printed circuit board non-metal powder / ABS resin composite material includes the following steps:

[0056] Step 1. Material pretreatment:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com