A method and device for improving the performance of mg2ni type hydrogen storage alloy

A hydrogen storage alloy and alloy technology, applied in the field of rapid solidification treatment to prepare Mg2Ni type hydrogen storage alloys, can solve the problems of reduced alloy capacity and kinetic properties, inability to mass-produce, poor cycle performance, etc., to achieve improved electrochemical discharge Capacity and kinetic performance, increase in electrochemical capacity and cycle life, and the effect of improving kinetic performance at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

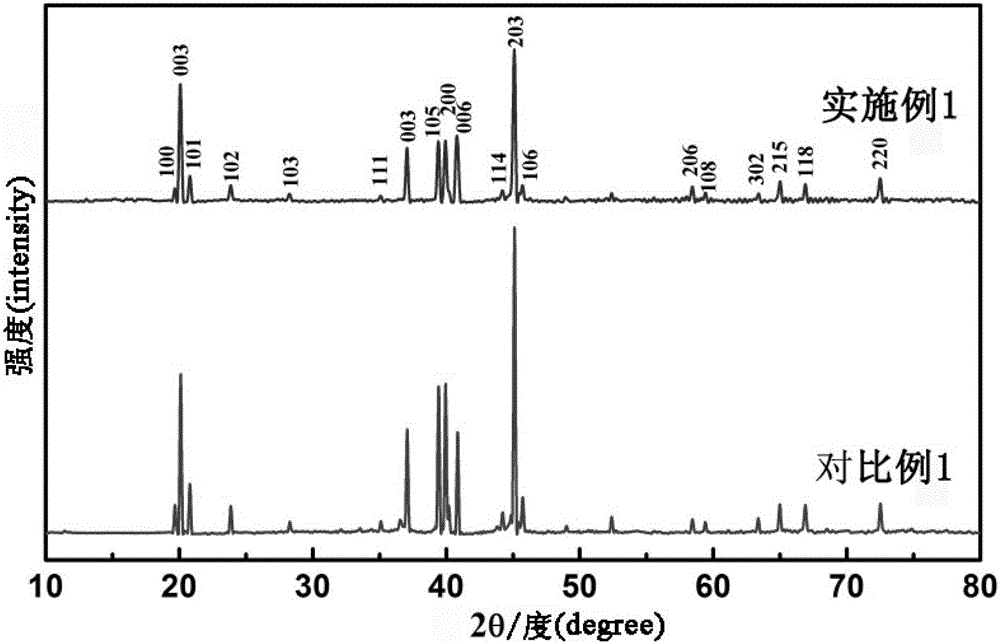

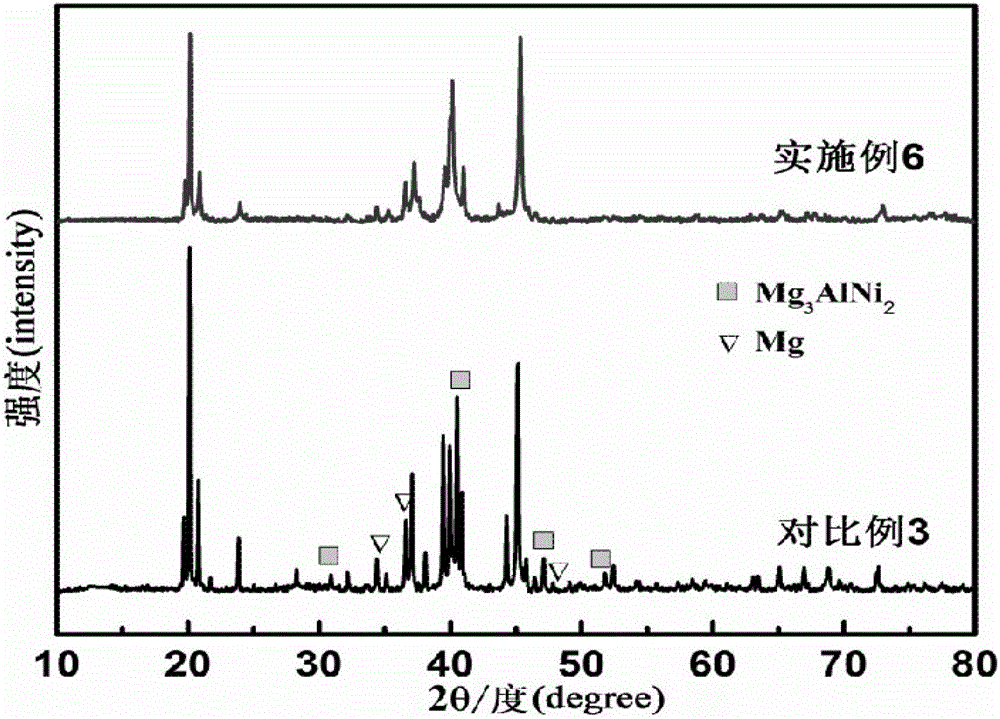

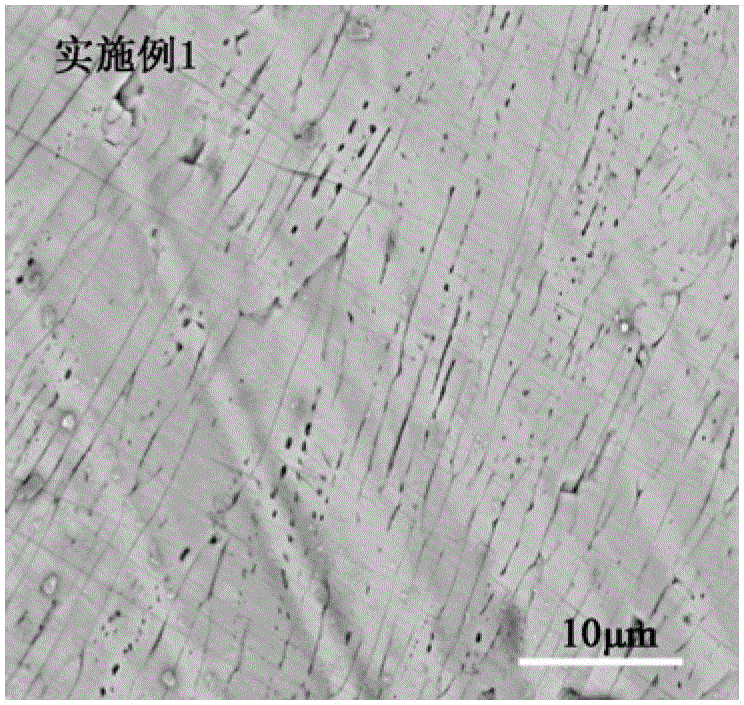

Embodiment 1

[0036] The alloy composition used is Mg 2 Ni. Grind the hydrogen storage alloy to remove the surface oxide film and impurities, and knock the alloy into small pieces and place it in a quartz tube with a hole diameter of 1mm at the lower end, and put it into the above device. The distance between the lower end of the quartz tube and the surface of the copper roller is 1mm. When preparing samples, vacuumize the melting chamber to 20-30Pa and then fill it with high-purity argon gas with a purity of 99.999%. After repeating 3 times, fill it with argon gas until the pressure gauge in the main cavity shows -0.04MPa. After the master alloy is completely melted by induction heating, the alloy melt is sprayed under the pressure of 0.08MPa onto the surface of a copper roller rotating at a line speed of 10m / s to quickly solidify, and a thin strip of Mg 2 Ni hydrogen storage alloy. Afterwards, the prepared hydrogen storage alloy strips were ground and sieved under argon protection in a ...

Embodiment 2

[0038] The alloy composition used is Mg 2 Ni. Grind the hydrogen storage alloy to remove the surface oxide film and impurities, and knock the alloy into small pieces and place it in a quartz tube with a hole diameter of 1mm at the lower end, and put it into the above device. The distance between the lower end of the quartz tube and the surface of the copper roller is 1.5mm . When preparing samples, vacuumize the melting chamber to 20-30Pa and then fill it with high-purity argon gas with a purity of 99.999%. After repeating 3 times, fill it with argon gas until the pressure gauge in the main cavity shows -0.04MPa. After the master alloy is completely melted by induction heating, the alloy melt is sprayed under the pressure of 0.08MPa onto the surface of a copper roller rotating at a line speed of 20m / s to rapidly solidify, and the thin strip-shaped Mg 2 Ni hydrogen storage alloy. Afterwards, the prepared hydrogen storage alloy strips were ground and sieved under argon protec...

Embodiment 3

[0040] The alloy composition used is Mg 2 Ni 0.9 mn 0.1 . Grind the hydrogen storage alloy to remove the surface oxide film and impurities, and knock the alloy into small pieces and place it in a quartz tube with a hole diameter of 1mm at the lower end, and put it into the above device. The distance between the lower end of the quartz tube and the surface of the copper roller is 1.5mm . When preparing samples, vacuumize the melting chamber to 20-30Pa and then fill it with high-purity argon gas with a purity of 99.999%. After repeating 3 times, fill it with argon gas until the pressure gauge in the main cavity shows -0.04MPa. After the master alloy is completely melted by induction heating, the alloy melt is sprayed under the pressure of 0.08MPa onto the surface of a copper roller rotating at a line speed of 20m / s to rapidly solidify, and the thin strip-shaped Mg 2 Ni 0.9 mn 0.1 hydrogen storage alloy. Afterwards, the prepared hydrogen storage alloy strips were ground an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com