Laser cladding method for roller

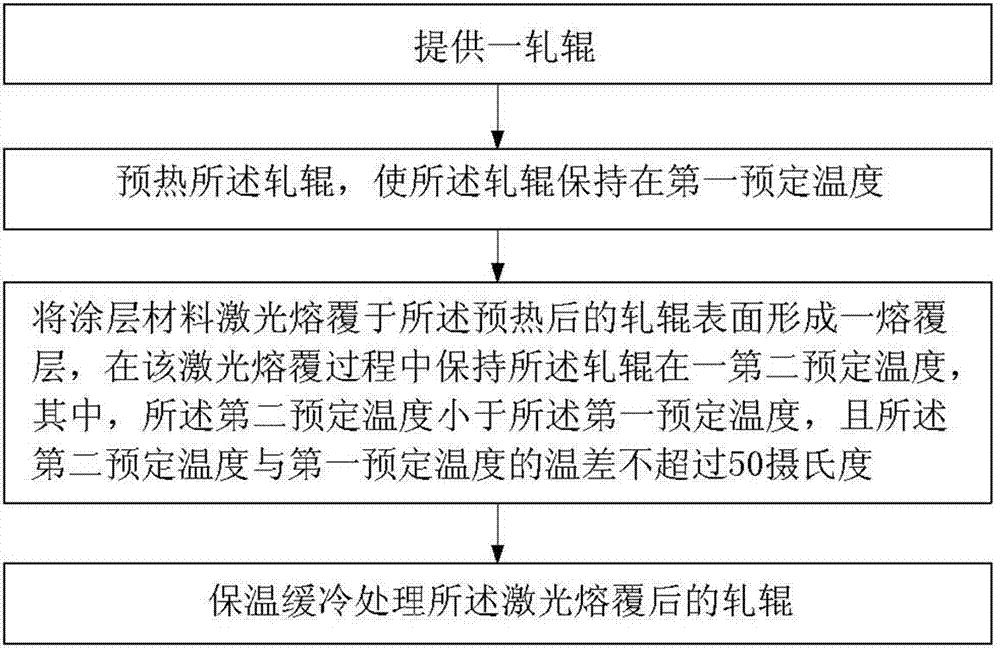

A laser cladding and rolling technology, which is applied in the coating process and coating of metal materials, can solve the problems of easy cracking and large thermal stress in the cladding layer, and achieve stable and reliable alloy composition and performance of the cladding layer. The effect of increasing the amount of steel and reducing the roll consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

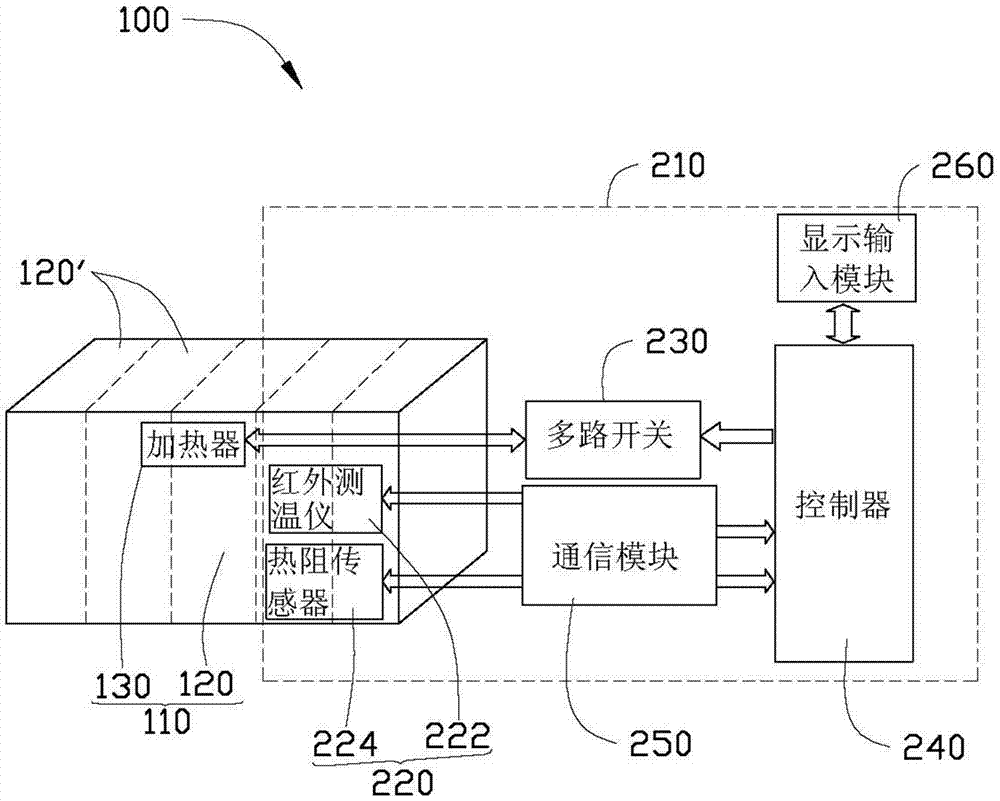

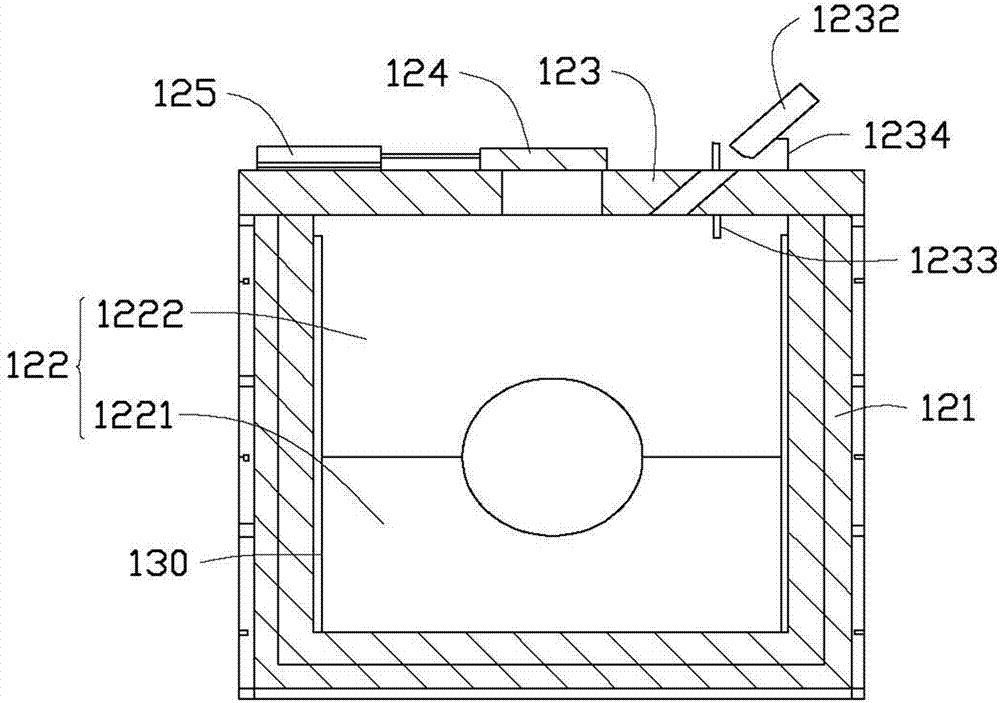

Method used

Image

Examples

Embodiment 1

[0091] The selected material of the roll is semi-steel. The size specification of the roll is Φ900mm×1550mm×2750mm. The dimension specification of the roll refers to the diameter of the roll, the length of the working surface and the total length of the roll. The cladding layer is arranged on the working surface of the roll. The above-mentioned method of the present invention is used to carry out laser cladding repair treatment on the roll. Among them, the process parameters of the laser cladding process are:

[0092] (1) Laser cladding process: laser power 10KW, scanning speed 720mm / min, spot diameter 15x1.5mm, lap rate 50%, single pass cladding thickness 3.5mm, powder feeding width 15mm, cladding material is iron-based alloy powder.

[0093] (2) Heat treatment process parameters: roll preheating temperature 550-580°C, heating rate 200°C / hour, heat preservation for 1.5 hours; heating and heat preservation temperature during cladding process 520±20°C; 380±20°C for 5 hours ...

Embodiment 2

[0100] The differences between this embodiment and Embodiment 1 are:

[0101] The material of the roll is 70Mn2, and the specification is φ650mm×1250mm×2050mm. Using the method of the present invention to carry out laser cladding repair on the working surface of the roller, the process is as follows:

[0102] (1) Laser cladding process: laser power 8KW, scanning speed 600mm / min, spot diameter 15x1.5mm, lap rate 40%, single cladding thickness 3.0mm, powder feeding width 15mm;

[0103] (2) Heat treatment process parameters: roll preheating temperature 480-520°C, heating rate 150°C / hour, heat preservation for 1 hour; heating and heat preservation temperature 450±20°C during cladding; 380±20°C for 4 hours immediately after processing Keep warm, then turn off the power and cool slowly to room temperature.

[0104] In this embodiment, after the roll is repaired by laser cladding, a good high-speed steel alloy cladding layer is obtained. The cladding layer has a hardness of HRC61-6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com