Double-output composite boiler

A dual-output, furnace technology, applied in the direction of heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of wasting energy, inability to fully utilize boiler heat, and incomplete energy recovery of exhaust smoke, etc., to achieve multi-heat energy The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

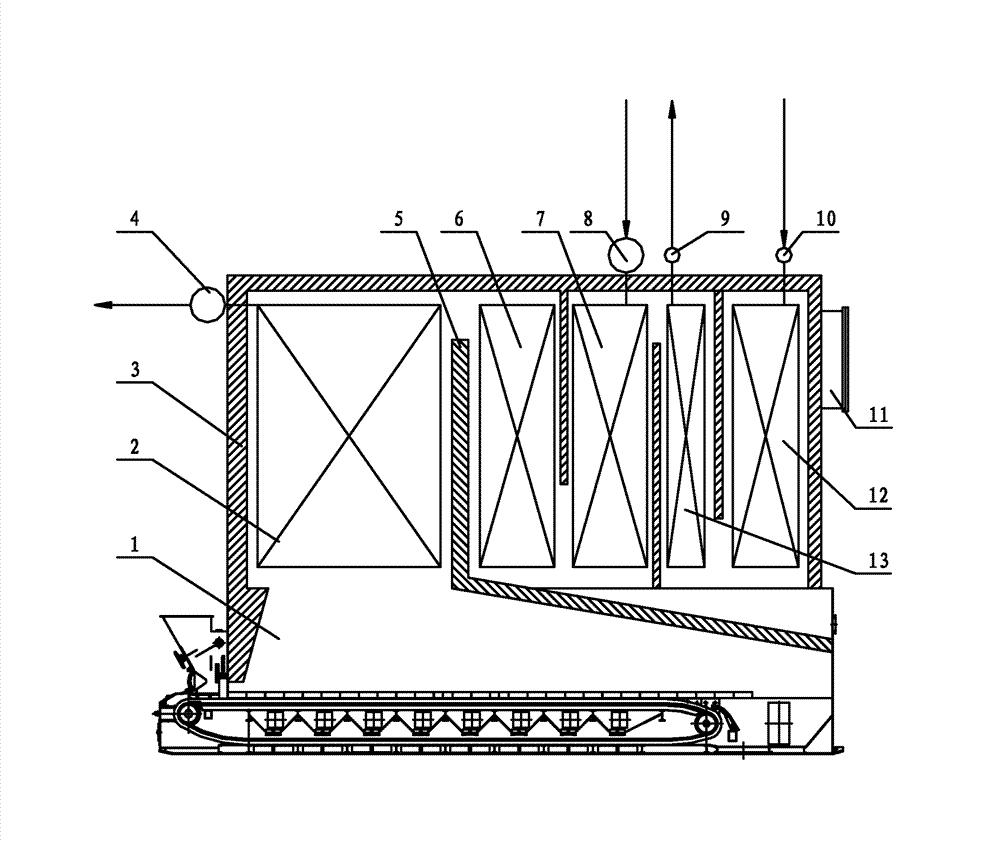

[0017] Such as figure 1 As shown, a kind of dual-output composite furnace of the present invention comprises a boiler body 3, a furnace 1 and a flue in the boiler body 3, a heat-conducting oil heat absorbing device 2 is arranged in the furnace, and a heat carrier is also arranged in the flue The heat absorbing device, the heat carrier heat absorbing device includes two heat carrier heat absorbing and convective sections 12 and 13 connected in series. The dual-output composite furnace of the present invention is provided with a heat-conducting oil device and a heat-carrier heat-absorbing device in sequence according to the flow direction of the flue gas, and the heat of the boiler is fully utilized to heat the heat-conducting oil and the heat carrier in turn, reduce the exhaust gas temperature, and realize environmental protection and energy saving; The carrier absorbs the waste heat of the flue gas at the rear of the flue, which can effectively avoid the acid dew corrosion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com