Method for determining content of water in Salvianolic acid for injection through near-infrared diffuse reflection spectrometry

A salvianolic acid and near-infrared technology, which is applied in color/spectral characteristic measurement, measuring devices, and material analysis through optical means, can solve the problems of large differences in detection results, low accuracy and sensitivity, and complicated operations. To achieve the effect of rapid quantitative analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

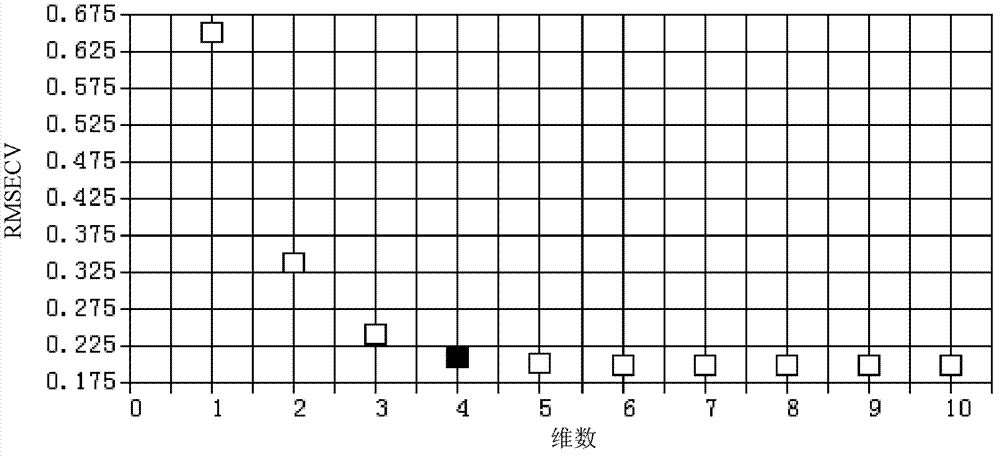

[0052] Step 1, establish a near-infrared quantitative calibration model:

[0053] a Take 30 samples of salvianolic acid for injection as a calibration set, and wipe the bottom of the vial with a cloth;

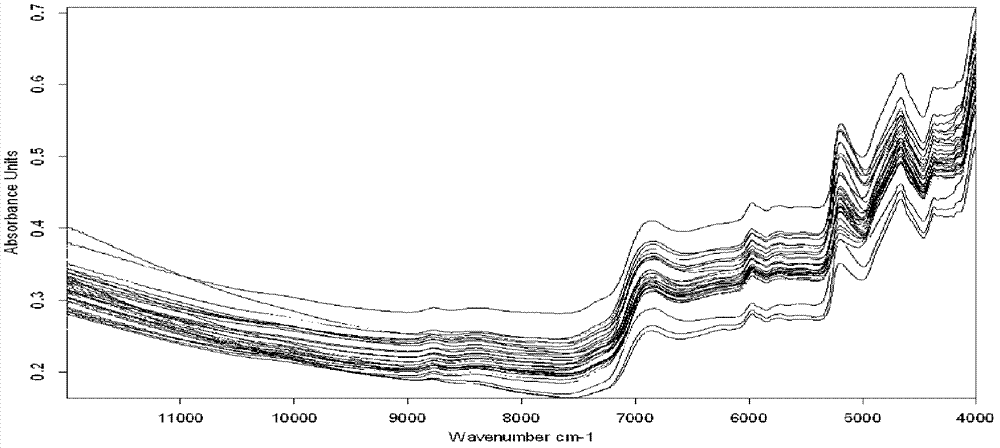

[0054] b After turning on the spectrometer and preheating the spectrometer for 1 hour, the scanning parameters are: measurement temperature: 21-25°C, humidity: 51-58%, diffuse reflection detection, and the scanning wavelength range is 4000-12000cm -1 , resolution 8cm -1 , using air as a blank control to scan the background, and then scan from the bottom of the vial with a near-infrared diffuse reflectance spectrometer. Each sample is scanned 3 times, and the average spectrum is taken to obtain the calibration set sample spectrum.

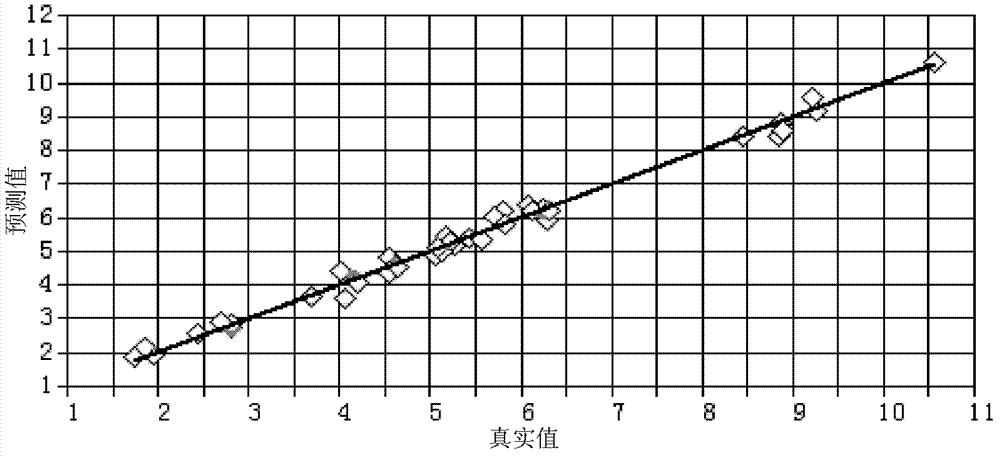

[0055] c With 30 parts of salvianolic acid correction set samples for injection in step a, obtain the moisture content in each sample according to the first method (drying method) of appendix IX H of the 2010 edition " Chinese Pharmacopoeia ", see ...

Embodiment 2

[0064] Step 1, establishing a near-infrared quantitative calibration model: the same as in Example 1;

[0065] Step 2, measure the moisture content in the sample:

[0066] a Take 3 samples of salvianolic acid for injection with batch number 20100302, and wipe the bottom of the vial with a cloth;

[0067] b using the same method in step 1b to obtain the spectrogram of the sample to be tested;

[0068] c According to the near-infrared quantitative calibration model established in step 1, the moisture content of the sample to be tested is measured, which are 4.662%, 4.544% and 4.044%, respectively. In order to further verify this test, the actual moisture content in the sample measured by the drying method in the Pharmacopoeia is 4.790%, 4.644% and 4.282%, respectively, and the errors of the two are within the allowable range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com