Method of probe and lead foot automatic aiming and probe station testing system thereof

A technology of probes and pins, which is applied in the field of testing equipment, can solve problems that cannot be ruled out, insufficient bonding, and low efficiency of manual alignment, and achieve the effect of enhancing bonding force and reducing contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

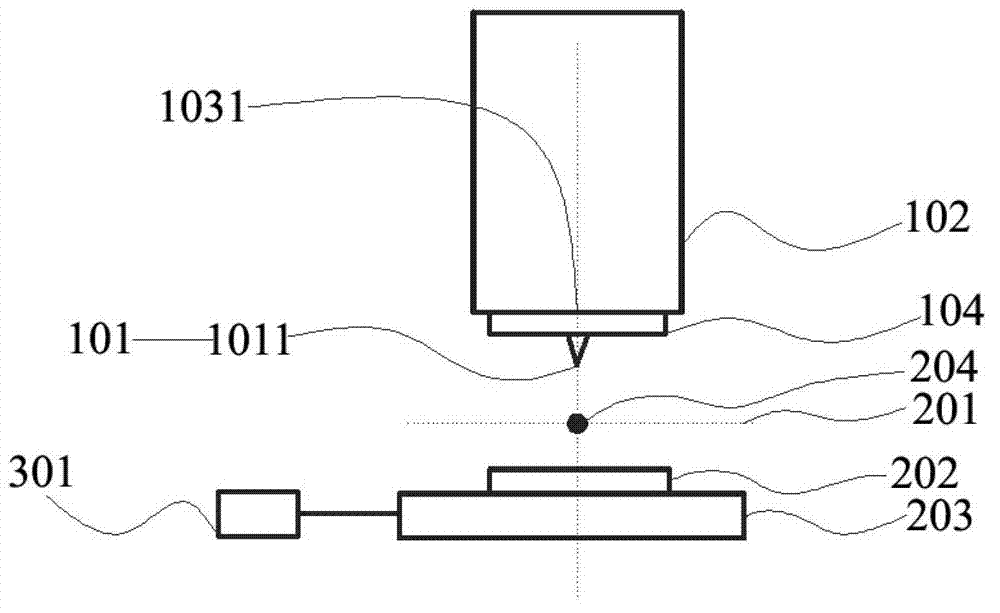

[0060] A probe station test system for automatic alignment of probes and pins:

[0061] Such as figure 1 As shown, a probe station testing system for automatic alignment of probes and pins includes: a probe 101 , a probe displacement device 102 , a probe frame 104 , a fixture 202 , a sample displacement device 203 , and a controller 301 .

[0062] Wherein, the probe 101 is used for contacting with the pin of the device under test, including a positioning test probe 1011, and the positioning test probe 1011 is a metal probe, a composite material probe, a one-dimensional material probe and / or a biological probe, fixed on the probe holder 104. The probe frame 104 is a support structure capable of fixing the probes, and is connected to the probe displacement device 102. The probe frame 104 is detachable, and the probes 101 can be replaced according to the relative positions of the pins of the device under test.

[0063] The probe displacement device 102 includes a driver, a powe...

Embodiment 2

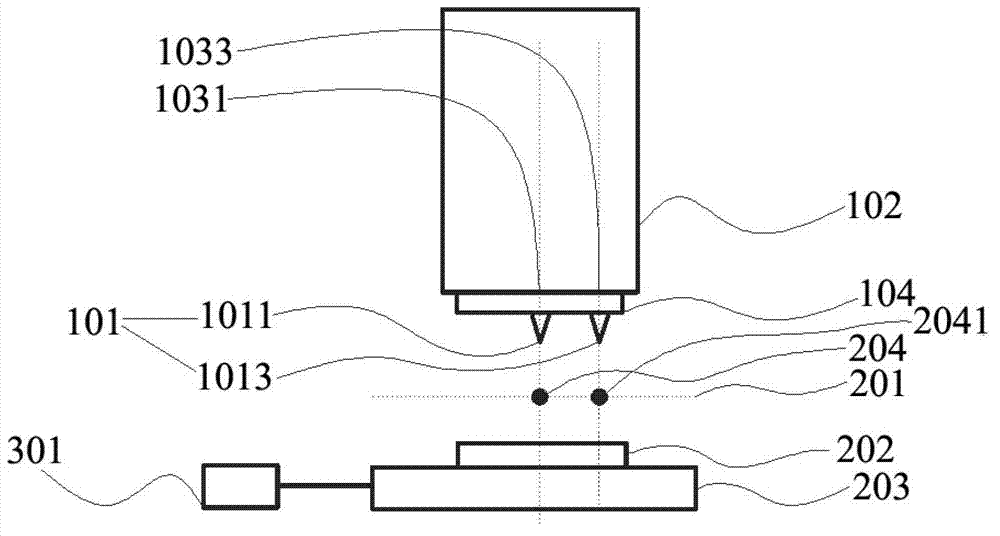

[0077] A probe station test system for automatic alignment of probes and pins:

[0078] Such as figure 2 As shown, a probe station testing system for automatic alignment of probes and pins includes: a probe 101 , a probe displacement device 102 , a probe frame 104 , a fixture 202 , a sample displacement device 203 , and a controller 301 .

[0079] Wherein, the probe 101 is used to contact the pins of the device under test, including a positioning test probe 1011 and an auxiliary positioning test probe 1013, the positioning test probe 1011 and the auxiliary positioning testing probe 1013 are metal probes, composite material probes The needles, one-dimensional material probes and / or biological probes are all fixed on the probe frame 104 . The probe frame 104 is a support structure capable of fixing the probes, and is connected to the probe displacement device 102. The probe frame 104 is detachable, and the probes 101 can be replaced according to the relative positions of the p...

Embodiment 3

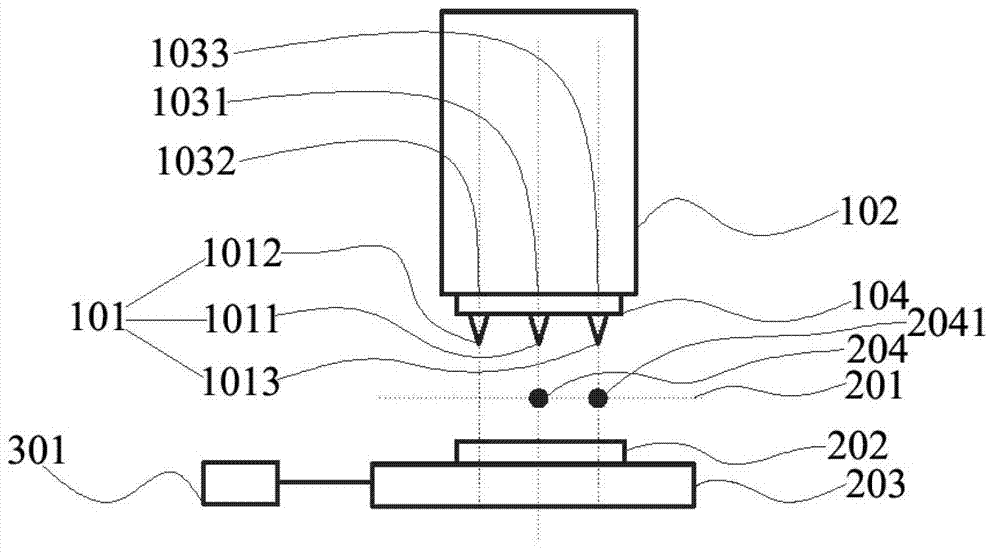

[0099] A probe station test system for automatic alignment of probes and pins:

[0100] Such as image 3 As shown, a probe station testing system for automatic alignment of probes and pins includes: a probe 101 , a probe displacement device 102 , a probe frame 104 , a fixture 202 , a sample displacement device 203 , and a controller 301 .

[0101] Wherein, the probes 101 are used to contact the pins of the device under test, including positioning test probes 1011 , auxiliary positioning testing probes 1013 and one or more non-positioning testing probes 1012 . Positioning test probes 1011, auxiliary positioning test probes 1013 and non-positioning test probes 1012 are all metal probes, composite material probes, one-dimensional material probes and / or biological probes, all of which are fixed on the probe frame 104 . The probe frame 104 is a support structure capable of fixing the probes, and is connected to the probe displacement device 102. The probe frame 104 is detachable,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Minimum spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com