Filament used for microcurrent electronic gun

An electron gun and micro-current technology, applied in the filament field, can solve problems such as unstable emission current and achieve low emission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

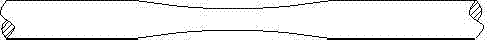

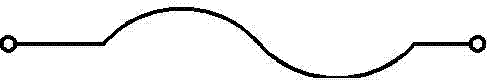

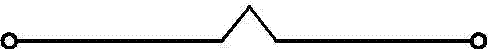

[0018] Such as figure 1 As shown, a filament for a micro-current electron gun, the material of the filament is tungsten, and the diameter of the middle part is gradually reduced by grinding, the diameter of the two ends of the filament is 0.15mm-0.2mm, and the diameter of the thinnest part of the middle part is 0.12mm-0.16mm, reducing the length of the filament to less than half of the original, because the emission efficiency of tungsten is low, which is beneficial to the control of the electron beam current; by reducing the surface area of the filament, the electron emission can be reduced by two orders of magnitude ; By grinding the middle of the filament, a larger temperature gradient between the middle and the edge is formed, thereby gradually expanding the electron emission area with the increase of the filament terminal voltage, which is beneficial to control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com