Ink box chip used for printer and ink box containing ink box chip

A technology of printers and ink cartridges, which is applied in printing and other directions, can solve the problem of small chip size, achieve the effect of small chip area, save space, and reduce the probability of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

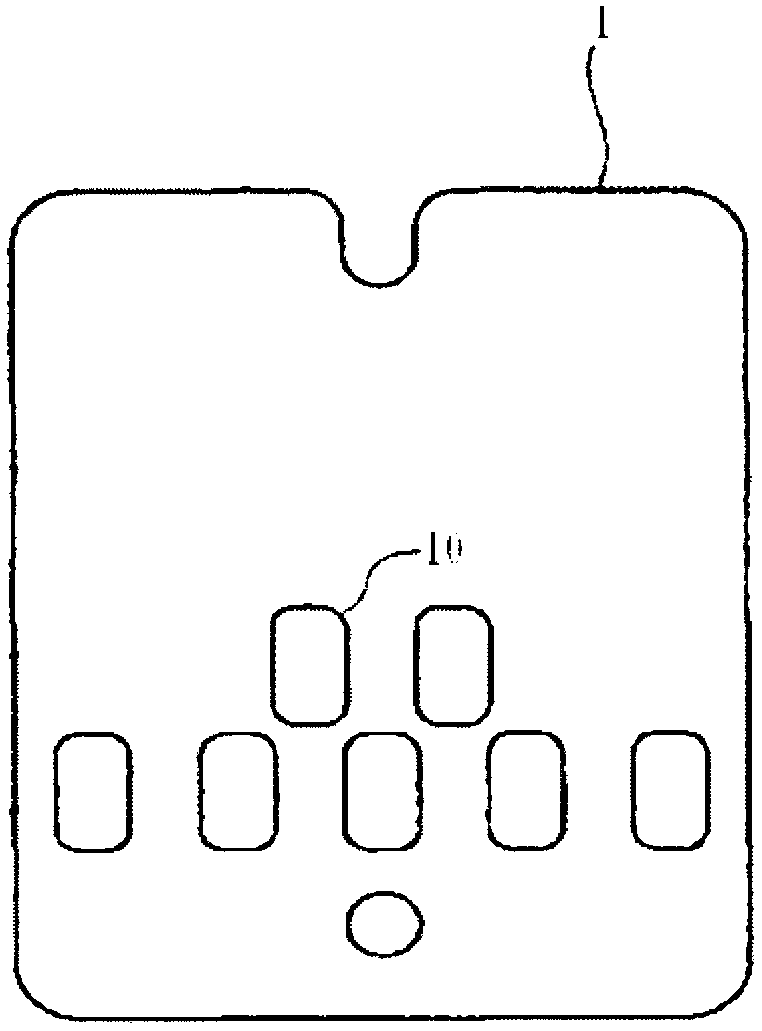

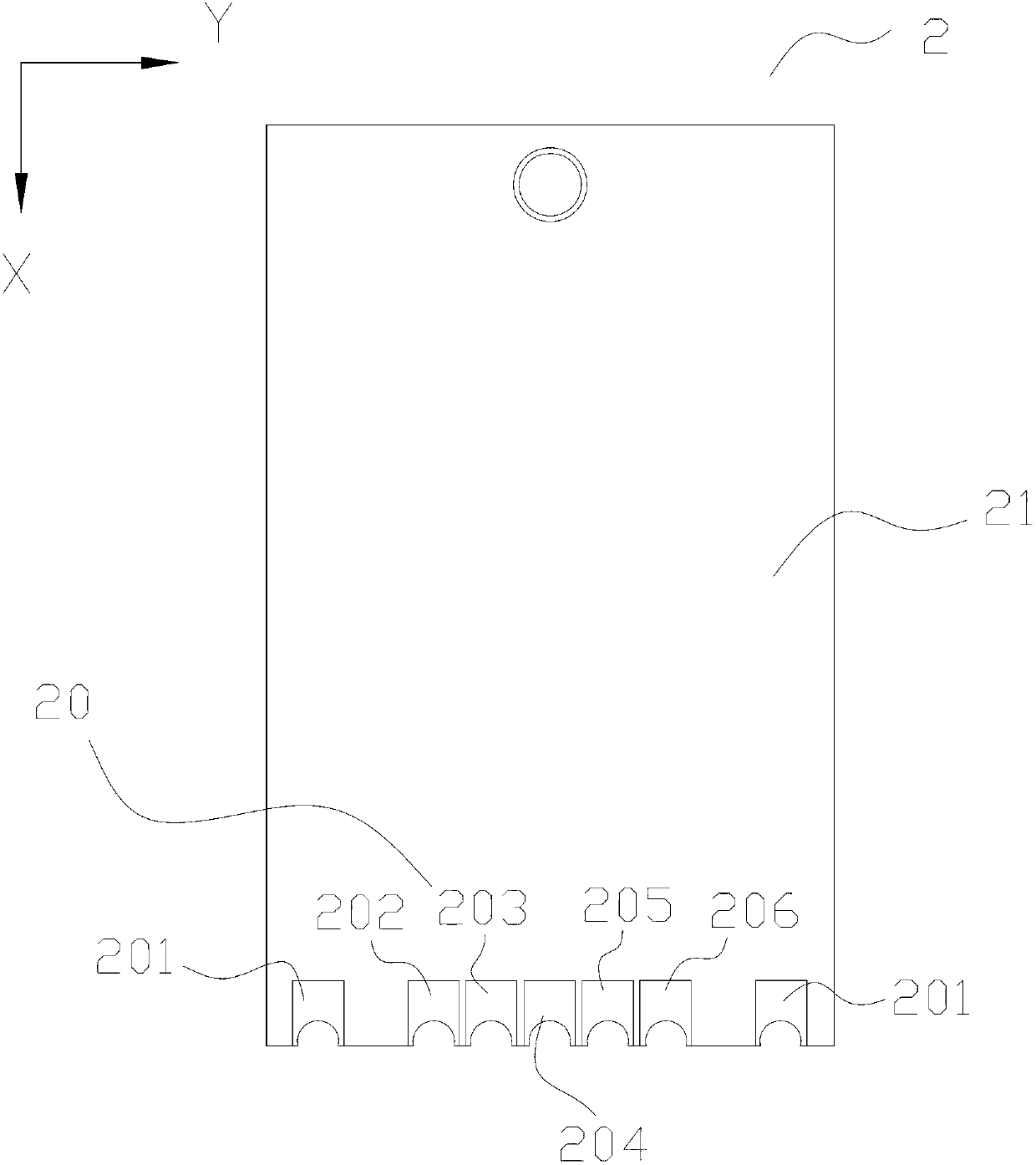

[0030] A chip used in ink cartridges used in printers, such as image 3 As shown, the chip 2 includes a substrate 21, a device circuit (not shown in the figure) and a plurality of contact terminals 20, and the plurality of contact terminals 20 include two high-voltage terminals 201, a power supply terminal 202, a clock terminal 203, and a ground terminal 204 , reset terminal 205 and data terminal 206; the high-voltage terminal 201 is arranged at both ends of the entire row of contacts, and the distance between the high-voltage terminal and other terminals is greater than the distance between other terminals; the ground terminal 204 is arranged at the two ends of the entire row of contacts In the middle, the ground terminal is farther from the high voltage terminal than any of the other contact terminals.

[0031] At least a part of each contact terminal in the plurality of contact terminals 20 is arranged on a straight line, at least one contact terminal in the plurality of co...

Embodiment 2

[0037] Figure 5 It is a schematic diagram of the chip structure of the second embodiment of the present invention, as shown in the figure, on the basis of the first embodiment, this embodiment makes the following improvements: the chip 2 includes a substrate 21, a device circuit (not shown in the figure) and a plurality of contacts Terminal 20, among the plurality of contact terminals 20, there are contact terminals 22 that only include the first contact surface, and contact terminals that include both the first contact surface and the second contact surface. Specifically, the chip in this implementation The clock terminal 220 and reset terminal 221 are contact terminals that only include the first contact surface (hereinafter referred to as the first group of contact terminals), and the rest are contact terminals that include both the first contact surface and the second contact surface ( Hereinafter referred to as the second group of contact terminals), the first group of c...

Embodiment 3

[0041] This embodiment is a modified example of Embodiment 1, such as Figure 7 As shown, the difference from Embodiment 1 is that the chip contact provided by this embodiment includes three contact surfaces, namely the first contact surface 23b located on the substrate layout surface and the third contact surface 23c perpendicular to the substrate layout surface, and the Between the first contact surface 23b and the third contact surface 23c, there is a second contact surface 23a with rounded or chamfered corners. The second contact surface 23a is a groove with an arc or slope. When the ink cartridge is installed in the printer, the elastic contacts of the printer are preferentially in contact with the second surface contact 23a. When the ink cartridge where the chip is located is caused by process errors and other problems, the depth of the chip installation is different, such as when the chip installation position is lower or higher. After the chip is loaded into the inkjet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com