Flexible flame-retardant rubber curtain with high strength, long service life and good visual effect and preparation method thereof

A flame-retardant rubber and visual effect technology, which is applied in the field of flexible flame-retardant rubber curtains and its preparation, can solve the problems that the curtain is not fire-resistant, the glass beads are not resistant to abrasion, and it is not convenient for storage, transportation and processing, so as to improve the durability Thermal aging resistance and flattening performance, satisfying the concept of safe use, and the effect of good polarized light reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

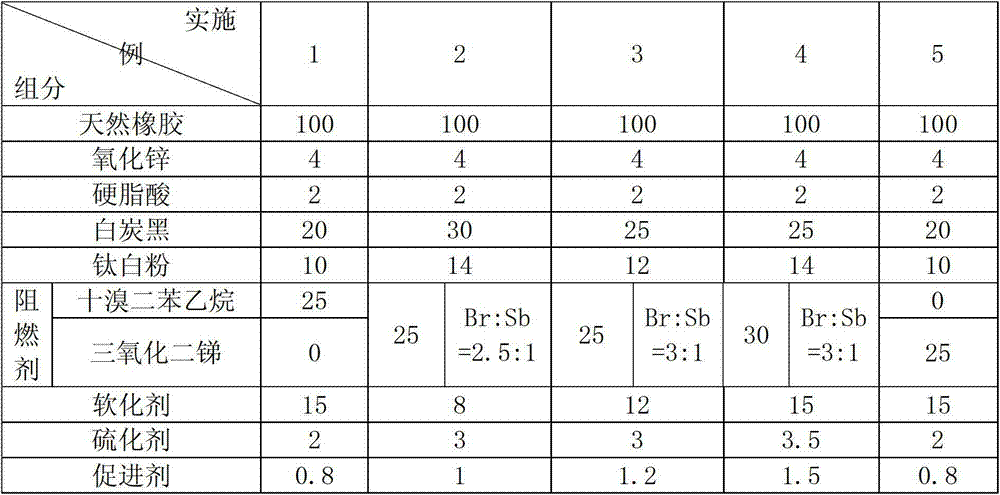

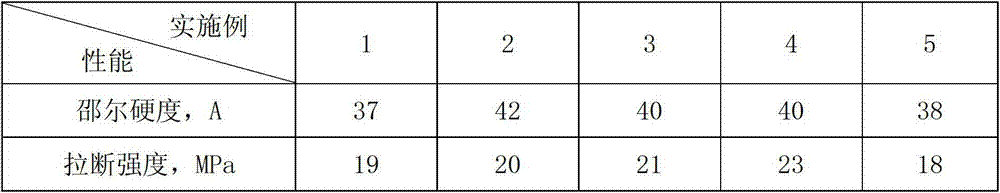

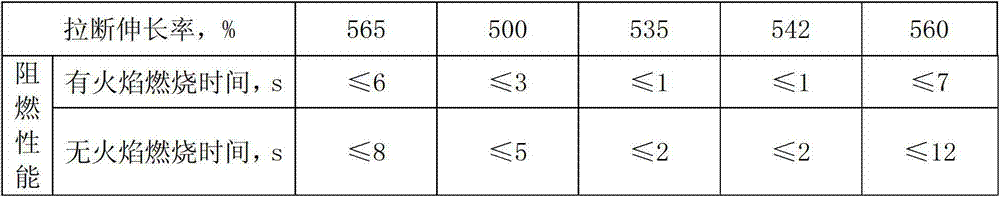

[0024] Example 1-10: Preparation of a flexible flame-retardant rubber curtain with high strength, long life and good visual effect.

[0025] The first step: see Table 1, 3, according to each embodiment, natural rubber of different weights, zinc oxide, stearic acid, white carbon black, titanium dioxide, flame retardant, softener are placed in a closed rubber mixer , Mixed rubber for 15 minutes at 100°C to prepare mixed rubber.

[0026] For example, for Example 1, the parts by weight of the following components are: natural rubber 100phr, zinc oxide 4phr, stearic acid 2phr, white carbon black 20phr, titanium dioxide 10phr, flame retardant (being decabromodiphenylethylene Alkane) 25phr, softener 15phr.

[0027] Second step: in the mixed rubber prepared in the first step, add vulcanizing agent and accelerator in different parts by weight in Table 1 and 3 respectively, and place it in an open rubber mixer for re-milling, and re-milling for 5 After the first pass, the film will be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com