Method for preparing aluminum matrix composite through high pressure solidification after semi-solid mechanical stirring

An aluminum-based composite material and mechanical stirring technology, which is applied in the field of preparing aluminum-based composite materials, can solve the problems of harmful reinforcement and metal, and achieve the effects of uniform distribution and high nucleation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

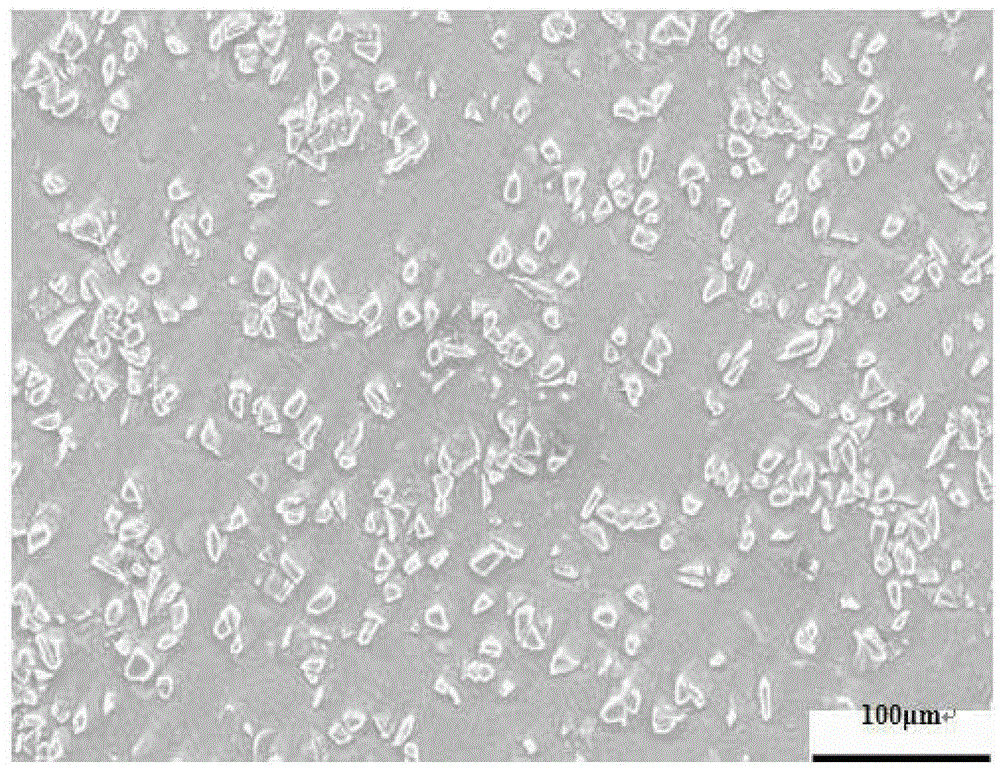

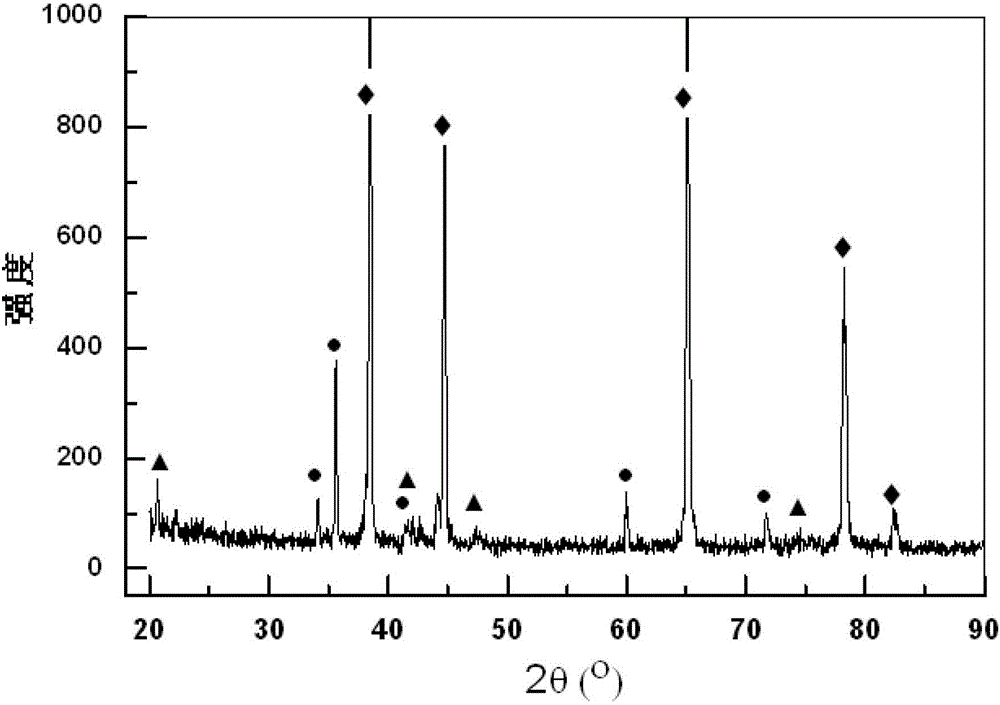

[0026] Specific Embodiment 1: In this embodiment, the method for preparing aluminum-based composite materials by high-pressure solidification after semi-solid mechanical stirring is specifically prepared according to the following steps:

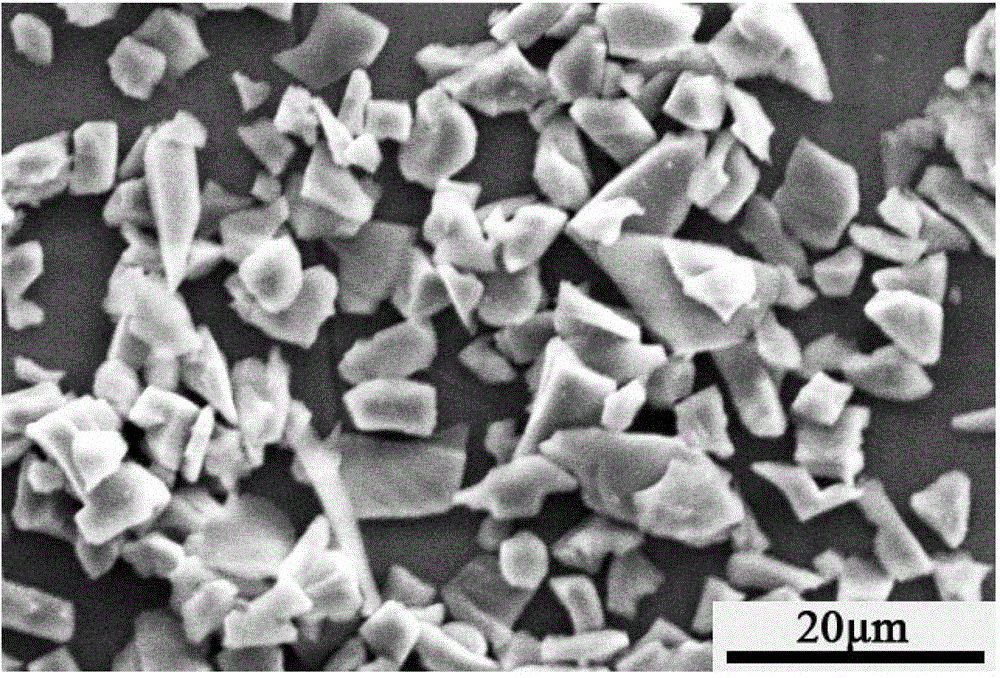

[0027] 1. Soak SiC particles in HF solution with a mass concentration of 4%~10%. The soaking time is 24h~72h. During this period, mechanically stir for 20min~40min every 5h~6h. When the pH reaches 6.8~7.2, SiC slurry is obtained, wherein the volume ratio of the mass of SiC particles to the HF solution is 9g~11g:45mL;

[0028] 2. Keep the SiC slurry obtained in step 1 at a temperature of 92°C~98°C for 8h~9h, and then at a temperature of 240°C~260°C for 8h~9h, and then use a 500-mesh sieve for sieving. Then keep warm at 600℃~700℃ for 1h~2h to obtain reinforcement particles;

[0029] 3. Put the clean aluminum alloy into the crucible, and pass through the argon gas with a flow rate of 100mL / min~200mL / min, raise the temperature to 700℃~750℃ to o...

specific Embodiment approach 2

[0034] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the particle size of the SiC particles is 5 μm˜50 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is: soak in step 1 for 30h~70h. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com