Laser reflective coaxial measuring instrument

A technology of laser reflection and measuring instrument, which is applied in the direction of measuring devices, instruments, and optical devices, etc. It can solve the problems of delay in measurement results, reduce the efficiency of measurement, reduce the accuracy of coaxiality measurement, etc., achieve length reduction and improve measurement The effect of precision and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the drawings and embodiments.

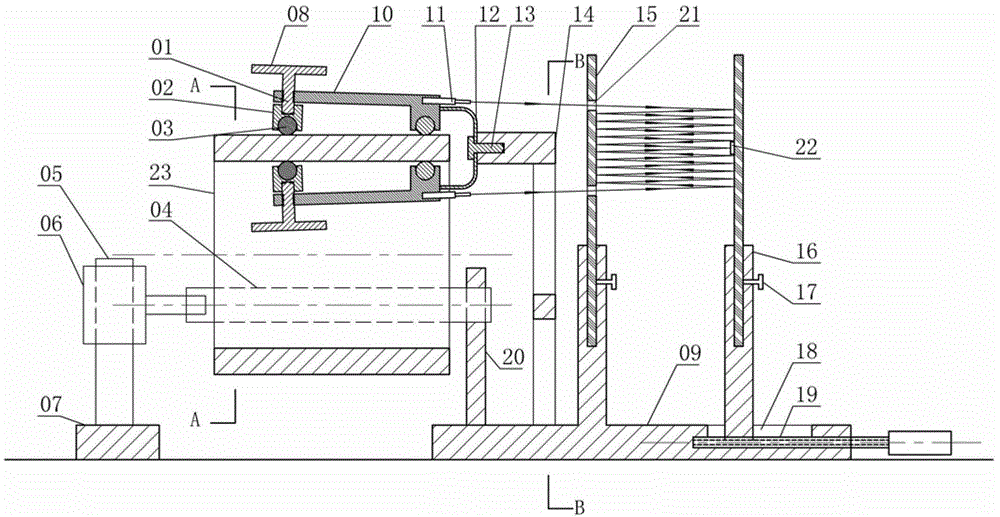

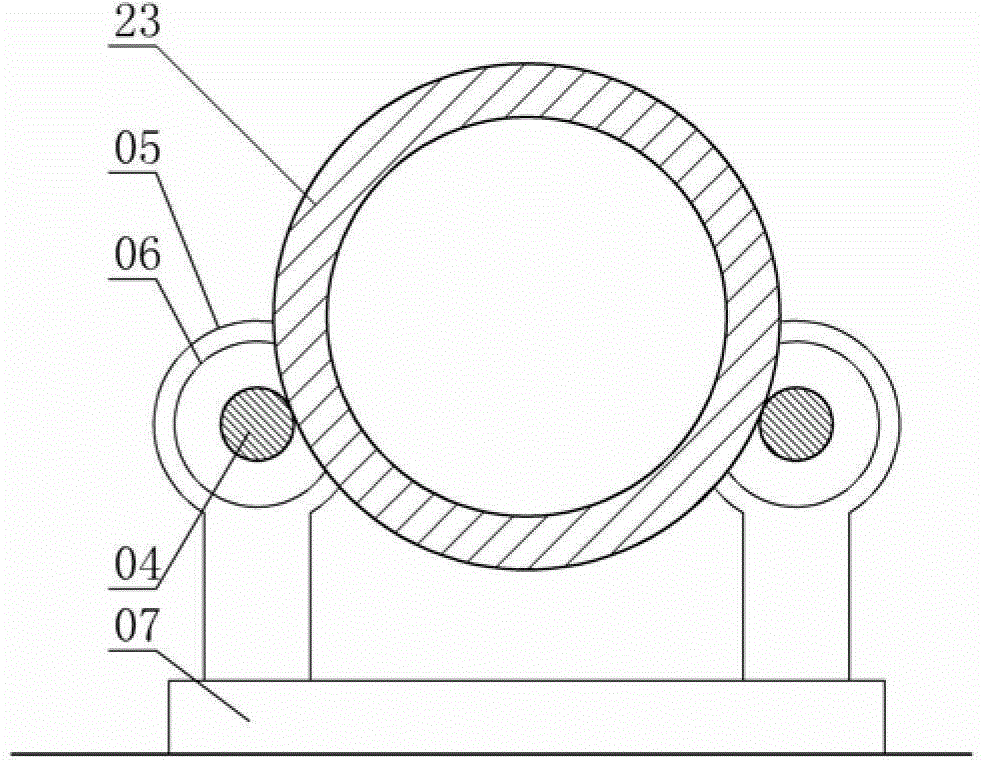

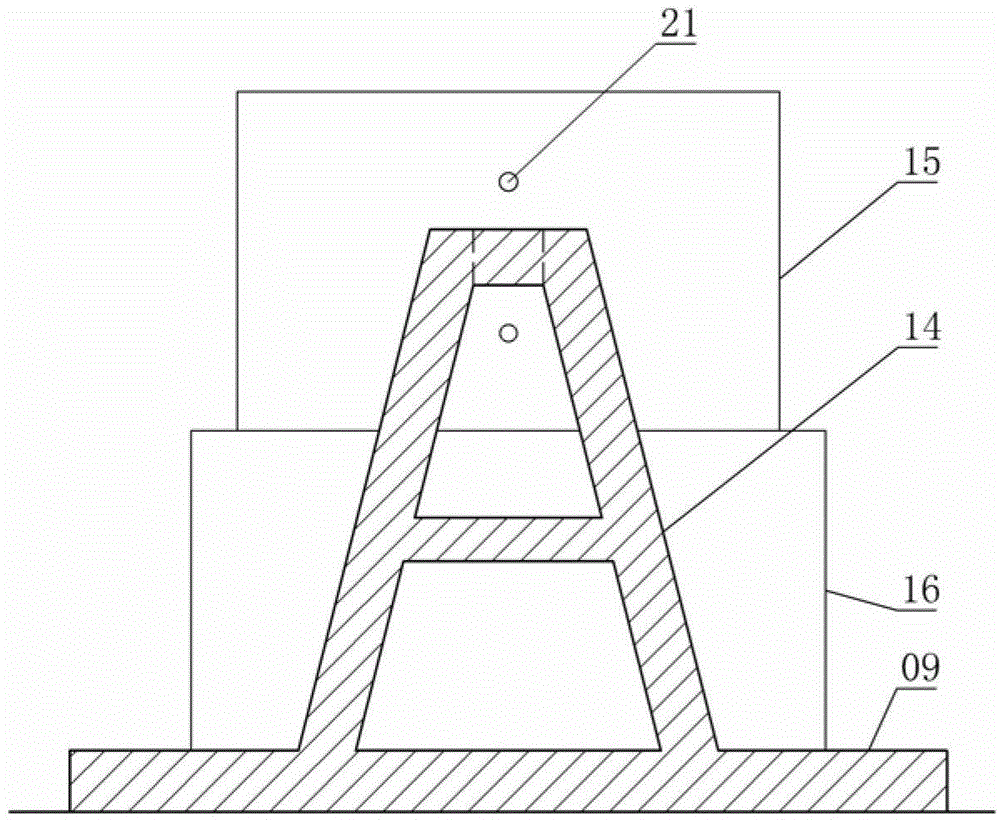

[0026] Laser reflection type coaxial measuring instrument, composed of adjusting rod 01, steel ball seat 02, steel ball 03, roller 04, motor frame 05, motor 06, motor seat 07, adjusting plate 08, mirror frame seat 09, clamp arm 10, The laser pointer 11, the spring sheet 12, the screw 13, the fixing frame 14, the flat mirror 15, the mirror frame 16, the fastening screw 17, the sliding groove 18, the adjusting handle 19, the shaft bracket 20, the entrance hole 21 and the projection target 22 are constituted.

[0027] Among them, the motor seat 07 and the mirror frame seat 09 are both metal cubes placed on a horizontal ground. The motor seat 07 is located on the left side of the mirror frame seat 09. The upper surface of the motor seat 07 has a pair of motors integral with the motor seat 07. The upper end of each motor frame 05 is fixed with a motor 06, and the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com