Determination method of furfuryl alcohol content in no-bake furan resin for casting

A technology of furan resin and determination method, applied in the field of detection, to achieve the effects of shortening the test period, reducing risks and losses, and stabilizing the quality of the casting mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

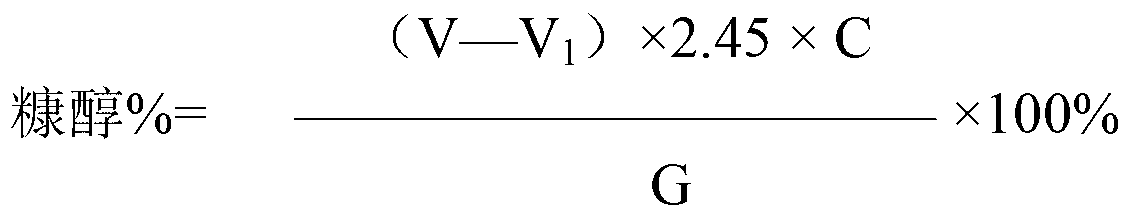

Method used

Image

Examples

Embodiment 1

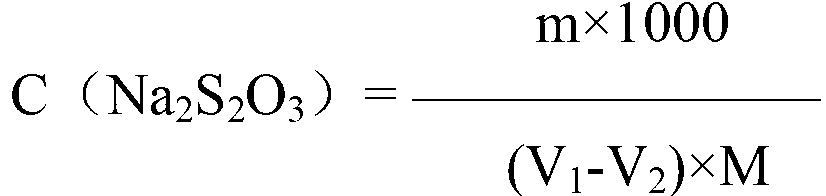

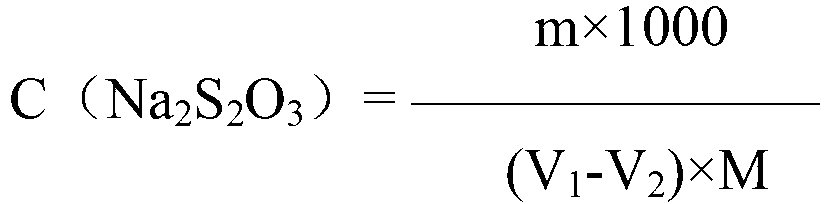

[0028] (1) For the calibration of 0.1mol / L sodium thiosulfate, record the calibration concentration as C:

[0029] Accurately weigh 26g sodium thiosulfate (Na 2 S 2 o 3 ·5H 2 O) (or 16g of anhydrous sodium thiosulfate), add 0.2g of anhydrous sodium carbonate, dissolve in 1000ml of water, boil slowly for 10 minutes, cool, and filter after two weeks in the dark.

[0030] Weigh 0.18g (accurate to 0.1000g) of benchmark potassium dichromate dried at 120°C±2°C to constant weight, put it in an iodine measuring bottle, dissolve it in 25ml of water, add 2g of potassium iodide and 20ml (20%) of sulfuric acid solution , shake well, and place in the dark for 10 minutes.

[0031] Add 150ml of water, titrate with the prepared sodium thiosulfate solution until the solution changes from blue to bright green, and conduct a blank test at the same time.

[0032] C ( Na 2 S 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com