A Predictive Control Method for Optimal Power of Doubly-fed Induction Power Generation System

A technology for optimizing power and predictive control, applied in wind power generation, electrical components, circuit devices, etc., to achieve the effect of improving operation control performance, strong robustness, and simple control structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings, and the purpose and effect of the present invention will be more obvious.

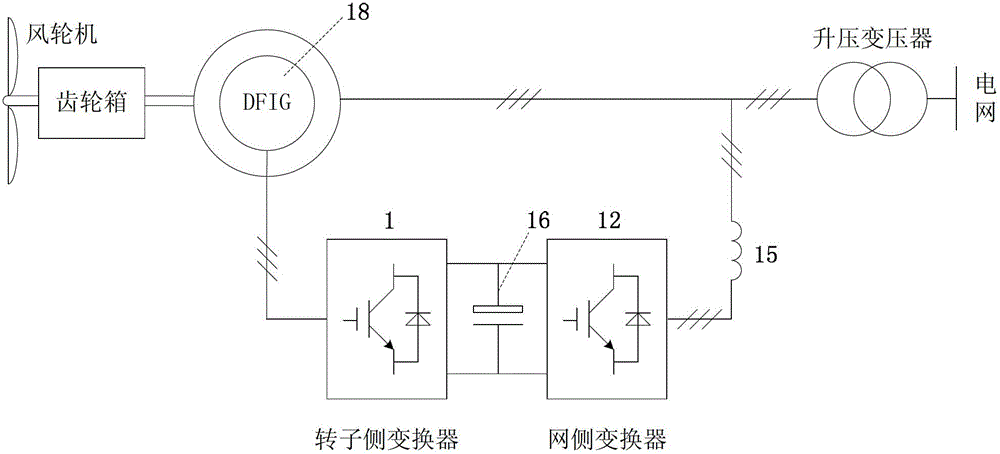

[0030] figure 1 It is a schematic diagram of a doubly-fed asynchronous wind turbine, including a wind turbine, a gearbox, a doubly-fed asynchronous wind generator DFIG18, a rotor-side converter RSC1, a grid-side converter GSC12, a filter inductor 15, a DC bus capacitor 16 and a step-up transformer .

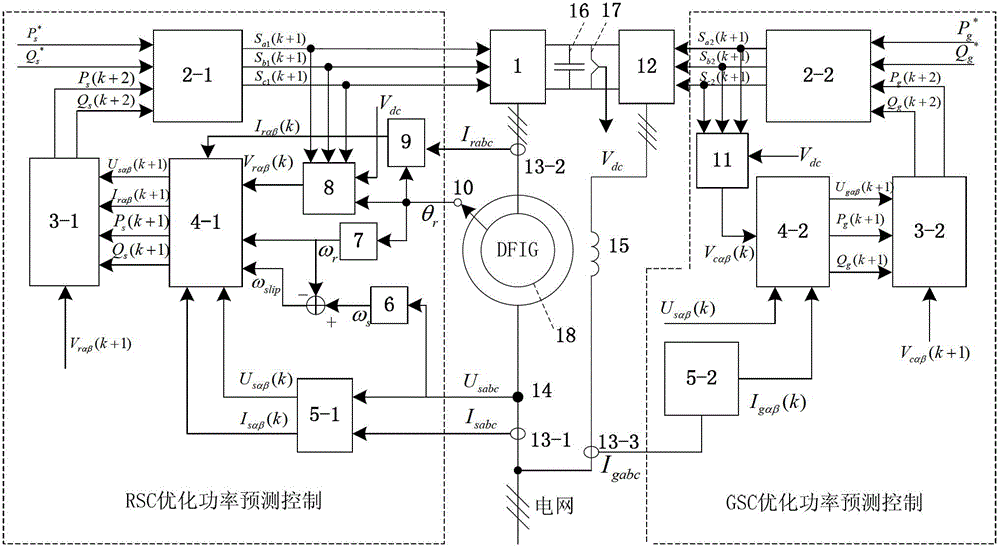

[0031] figure 2 It is a principle diagram of a coordinated optimization power prediction control method for a doubly-fed asynchronous wind power generation system proposed by the present invention. Taking a 2KW variable-speed constant-frequency DFIG as an example, the method for coordinated and optimized power predictive control of a doubly-fed asynchronous wind power generation system proposed by the present invention is adopted, wherein the optimized power predictive control of RSC1 is in the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com