Pulsed laser machining method and installation, particularly for welding, with variation of the power of each laser pulse

A laser processing method and laser pulse technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of complex and difficult welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Laser processing method of the present invention comprises the steps:

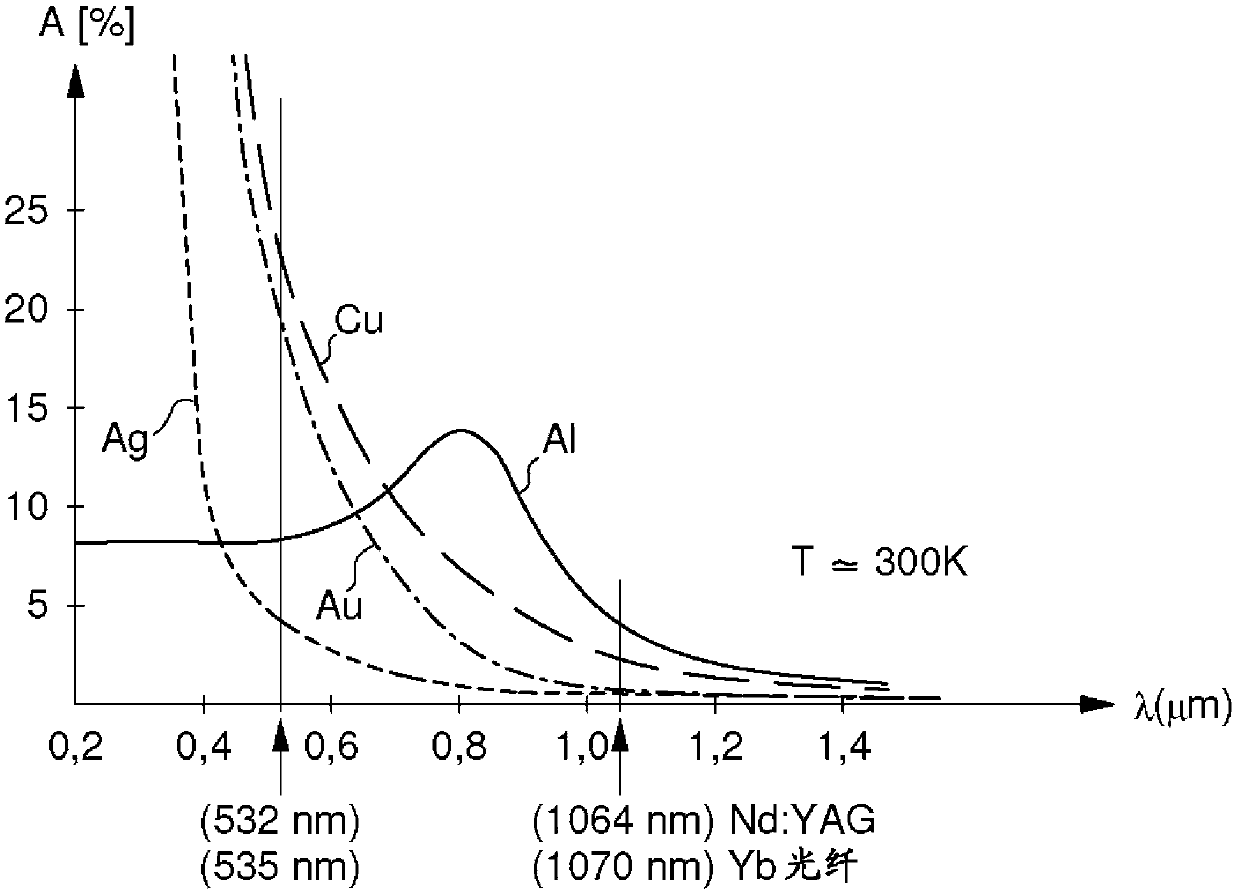

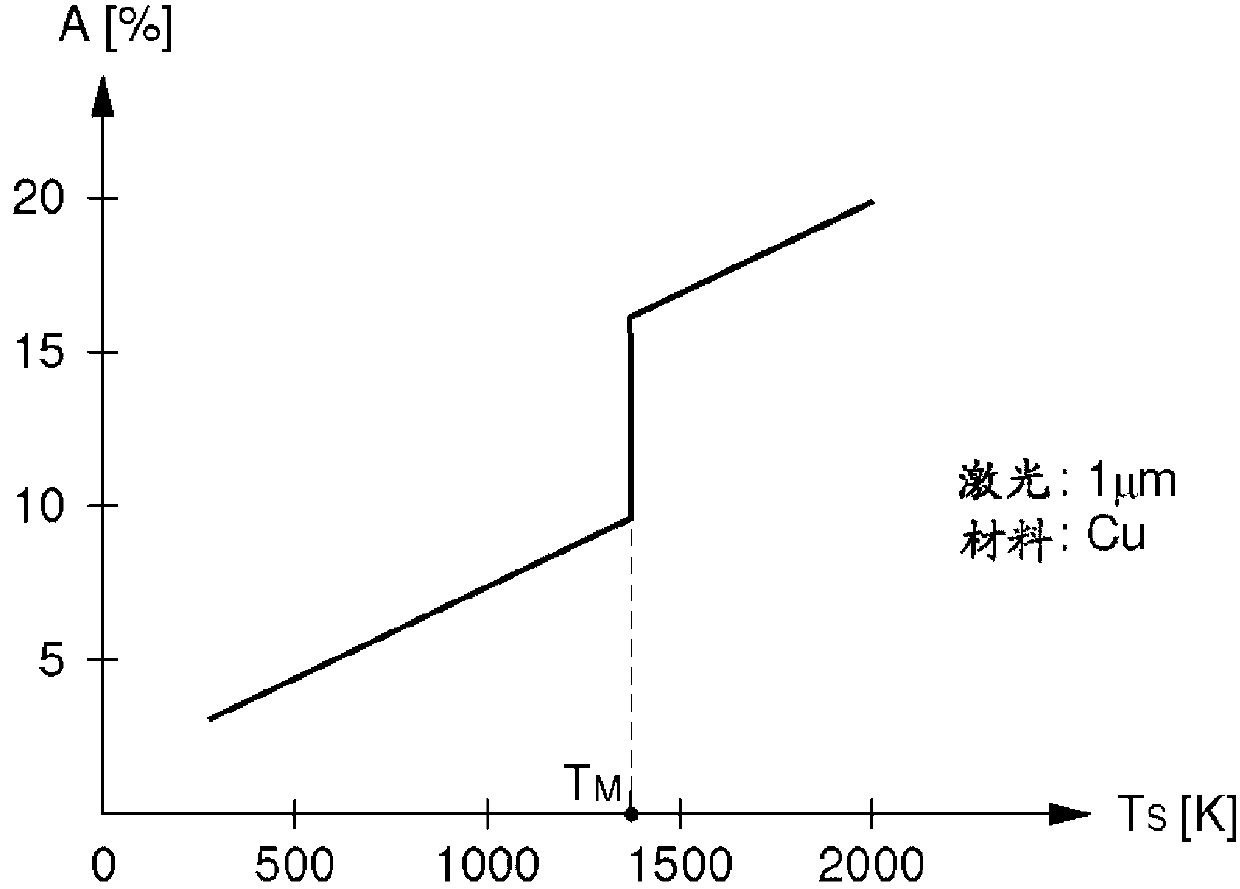

[0022] A) A laser source is used to generate a laser beam formed by a series of laser pulses with a wavelength of 700-1200 nm.

[0023] B) Using a nonlinear crystal to double the frequency of a portion of the laser beam.

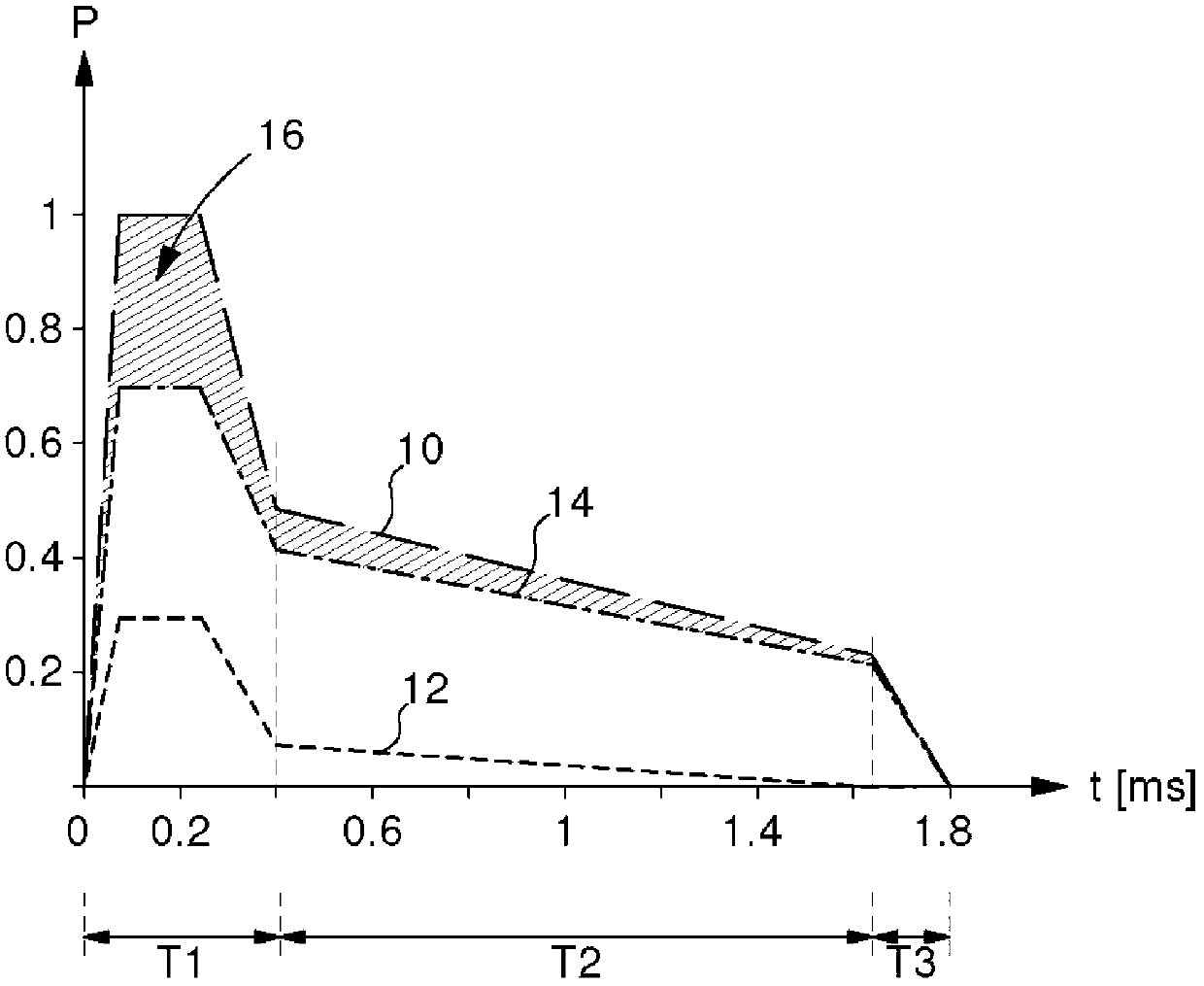

[0024] C) Vary the power during each emitted laser pulse such that, over the entire period of this laser pulse, the power profile has maximum peak power in the initial sub-period T1 or a portion of the pulse has maximum power for a duration longer than the initial sub-period T1 The period is longer and occurs in a subsequent second intermediate sub-period T2, with a power lower than said maximum power throughout the entire intermediate sub-period.

[0025] The variation in maximum power is at least twice the average power over the entire period of the laser pulse, increasing to said maximum power in less than 3 / 10 millisecond (0.3 ms) from the start of each laser pulse.

[0026]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com