Method for directly synthesizing Pt-Co bimetallic nanoparticles utilizing water phase and application

A bimetallic nano, pt-co technology, applied in the field of catalysis, can solve problems such as hindering metal sites and losing catalytic performance, and achieve the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 15

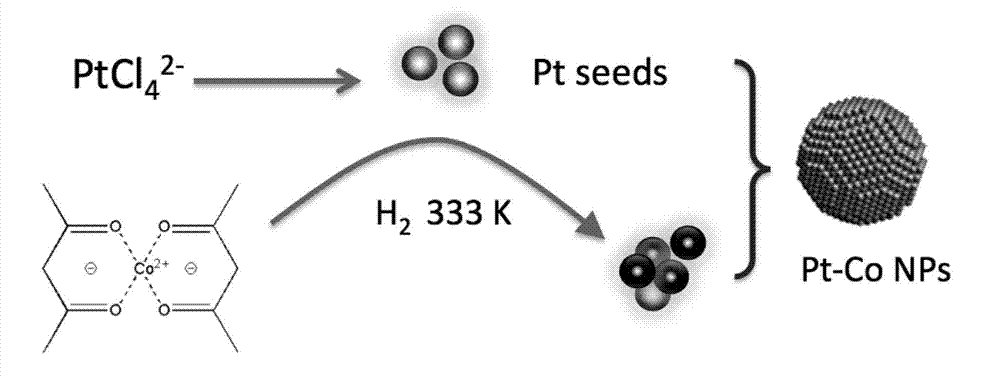

[0025] The synthesis of embodiment 15%Pt-Co nanoparticles

[0026] 0.042 g of platinum precursor salt potassium chloroplatinite and 0.586 g of cobalt precursor salt hydrated cobalt(II) acetylacetonate were dissolved in 40 mL of water, and 2.2 g of PVP was added at the same time. The mixture was transferred to a stainless steel reaction kettle and sealed well. Then fill the reaction kettle with 2MPa hydrogen, then stir rapidly and raise the temperature to 60°C, and reduce for 4 hours. Pt-Co bimetallic nanoparticles were obtained by magnetic separation.

Embodiment 210

[0027] The synthesis of embodiment 210%Pt-Co nanoparticles

[0028] 0.084 g of platinum precursor salt potassium chloroplatinite and 0.586 g of cobalt precursor salt hydrated cobalt(II) acetylacetonate were dissolved in 40 mL of water, and 2.2 g of PVP was added at the same time. The mixture was transferred to a stainless steel reaction kettle and sealed well. Then fill the reaction kettle with 2MPa hydrogen, then stir rapidly and raise the temperature to 60°C, and reduce for 4 hours. Pt-Co bimetallic nanoparticles were obtained by magnetic separation.

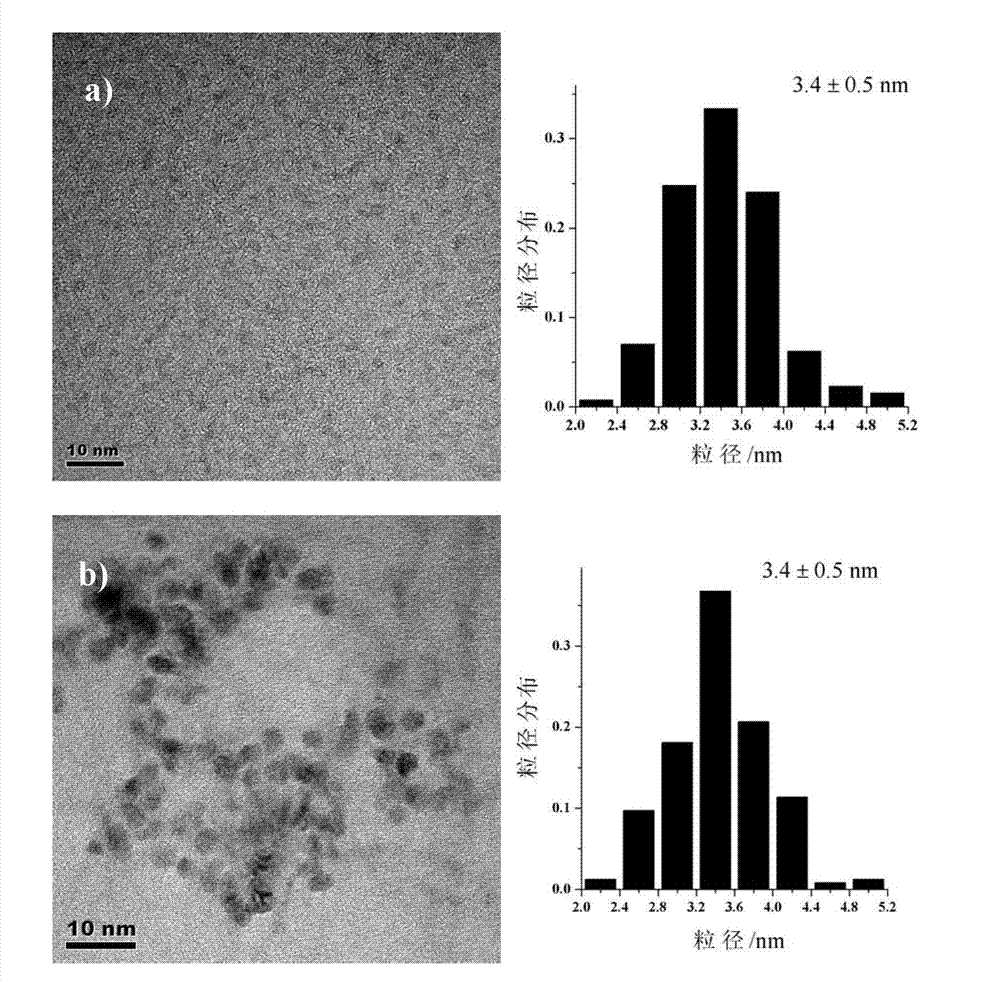

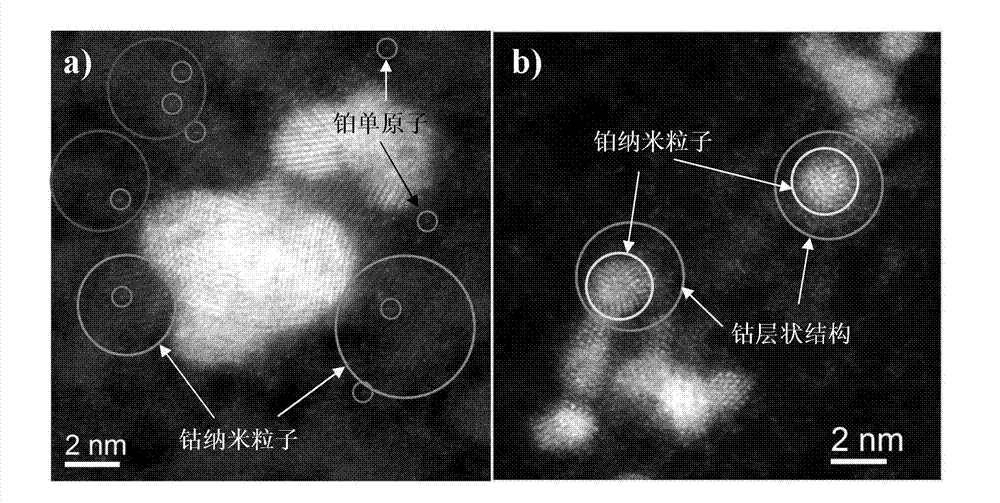

[0029] The particle size distribution of the synthesized 10% Pt-Co nanoparticles is as follows figure 2 As shown, the average particle size is 3.4±0.5nm. The specific structure of the 10% Pt-Co nanoparticles is as image 3 As shown, there are "cobalt monolayers grown on platinum particles" and "single-atom Pt-embedded Co nanoparticles" structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com