Bifocus laser processing system

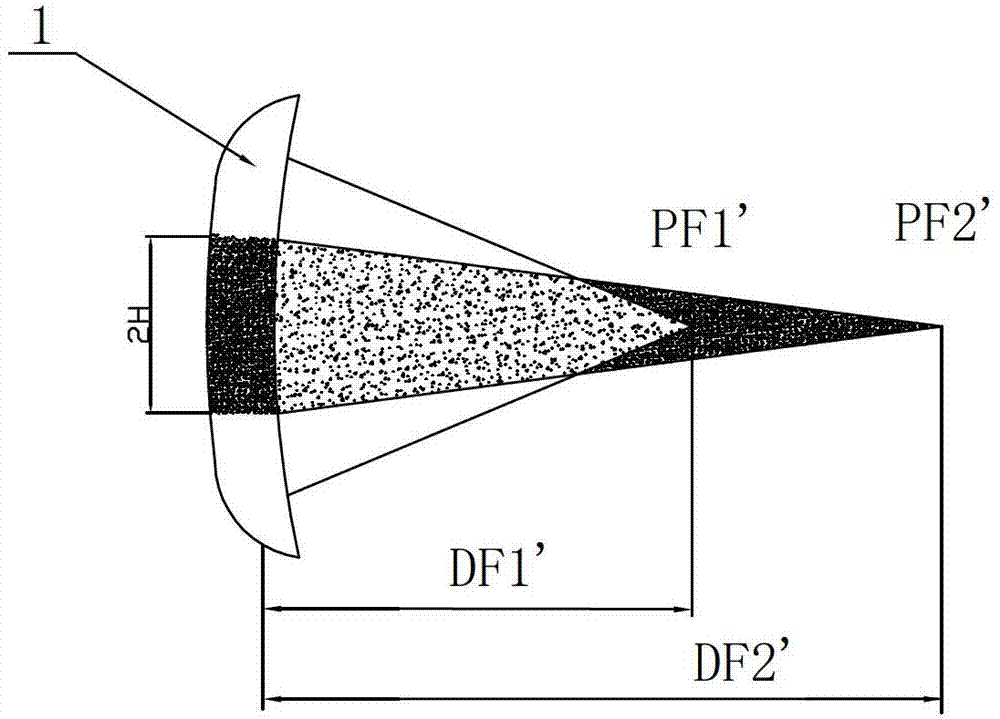

A laser processing and dual focus technology, applied in the laser field, can solve the problems of the laser power ratio being unchangeable and the inability to apply laser micromachining, etc., to achieve the effect of improving product quality, processing speed and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

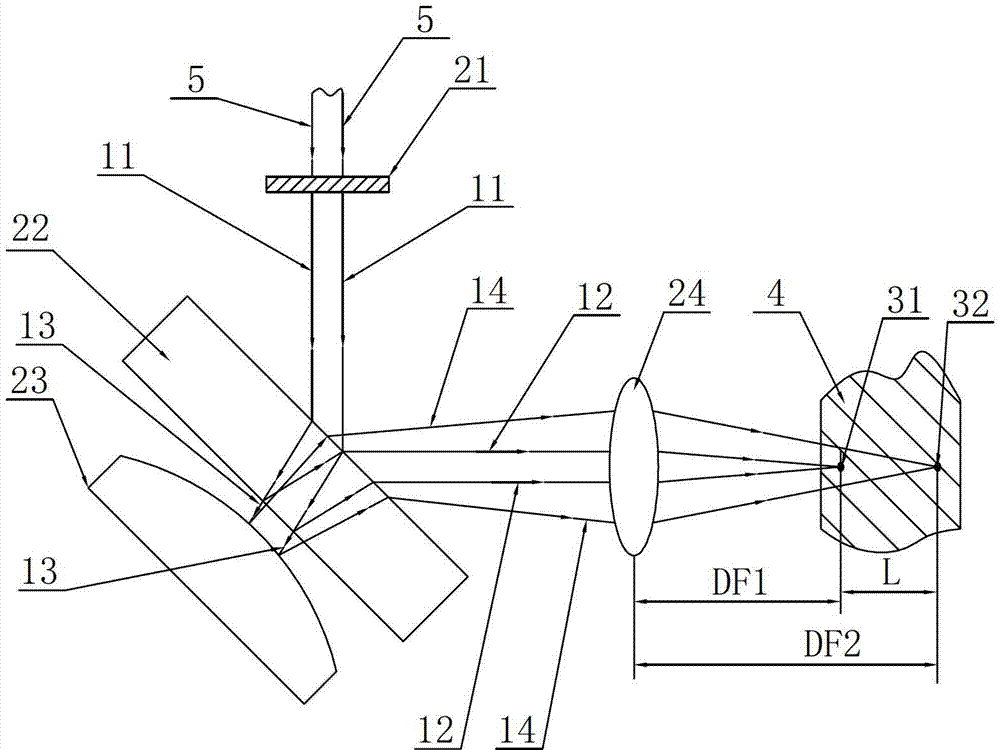

[0021] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The schematic embodiments and descriptions of the present invention are used to explain the technical solutions of the present invention, but are not intended to limit the present invention.

[0022] The dual-focus laser processing system of the present invention includes a wave plate 21, a beam splitter 22, a convex mirror 23 and a focusing mirror 24, such as figure 2 shown.

[0023] The laser beam 5 passes through the wave plate 21 to obtain the first beam 11 .

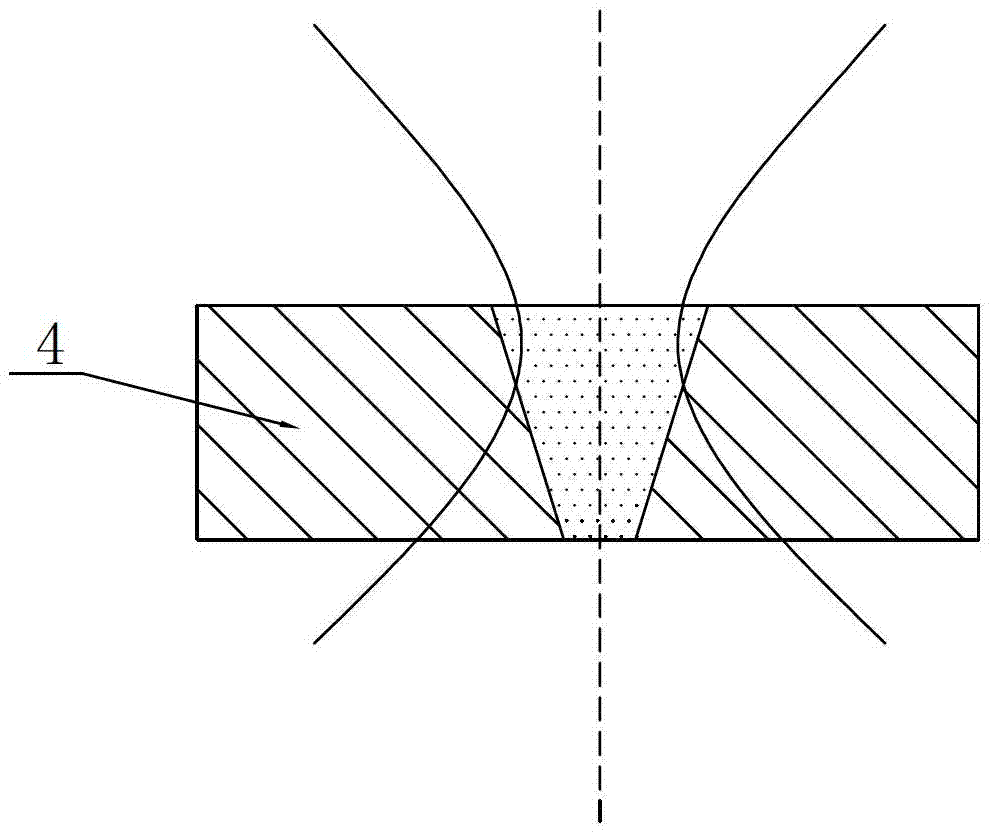

[0024] The first light beam 11 is reflected by the beam splitter 22 to obtain the second light beam 12, and the second light beam 12 is focused by the focusing mirror 24 into the first beam on the optical axis of the laser beam acting on the workpiece 4 to be processed. The focal point 31, the distance between the first focal point 31 and the center of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Focal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com