Water soluble Pt(II) catalyst precursor free from chlorine and nitrate and synthetic method thereof

A technology of nitrate and precursor, applied in the field of precursor compounds, can solve the problem of low water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

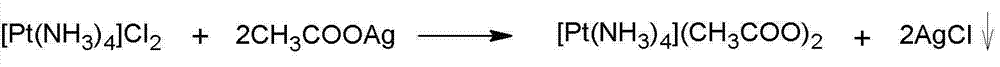

[0012] Embodiment 1, the synthesis of tetraammine platinum acetate (II)

[0013] Weigh 3.52 g (10 mmol) [Pt(NH 3 ) 4 ] Cl 2 ·H 2 Dissolve O in 50 mL of water, add 3.34 g (20 mmol) of silver acetate solid in batches under stirring, stir and react for 2 hours after the addition is complete, let stand, filter, wash the filter residue with 50 mL of water for 3 times, and combine the filtrate and washing liquid After concentrating to about 5 mL, add 50 mL of ethanol, stir for 15 minutes, let stand for 30 minutes, collect by filtration, and dry at 110°C for 2 hours to obtain 3.63 g of [Pt(NH 3 ) 4 ](CH 3 COO) 2 Product, yield 95.2%.

[0014] Structural characteristic parameters: Elemental analysis: measured values C 12.53%, H 4.81%, N 14.65%, Pt 51.02% are consistent with theoretical values C 12.60%, H 4.76%, N 14.69%, Pt 51.16%. IR (cm -1 , KBr) 3261, 3221 (s, ν(NH 3 )); 1696, 1652 (s, ν as (C=O)), 1405 (s, ν s (C=O)). 1 H NMR (D 2 O, ppm) 1.76 (s, 3H, CH 3 ...

Embodiment 2

[0015] Embodiment 2, the synthesis of tetraammine platinum acetate (II)

[0016] Take by weighing 333.8 grams of silver acetate, add 200 mL of water and stir it into a paste, then slowly add the paste to 352.0 grams of [Pt(NH 3 ) 4 ] Cl 2 ·H 2 Dissolve O in a solution of 3 L of water, stir for 3 hours, let stand, filter, wash the filter residue with 2 L of water for 3 times, combine the filtrate and washing liquid and concentrate to about 200 mL, add 2 L of ethanol, and stir for 30 minutes Let stand for 30 minutes, collect by filtration, and dry at 80° C. for 2 hours to obtain 385.0 grams of [Pt(NH 3 ) 4 ](CH 3 COO) 2 ·H 2 O product, yield 96.4%.

[0017] Structural characteristic parameters: Elemental analysis: measured values C 11.85%, H 5.03%, N 14.05%, Pt 48.82% are consistent with theoretical values C 12.03%, H 5.05%, N 14.03%, Pt 48.85%. IR (cm -1 , KBr) 3403 (s, ν(H 2 O)); 3261, 3221 (s, ν(NH 3 )); 1696, 1652 (s, ν as (C=O)), 1405 (s, ν s (C=O)). ...

Embodiment 3

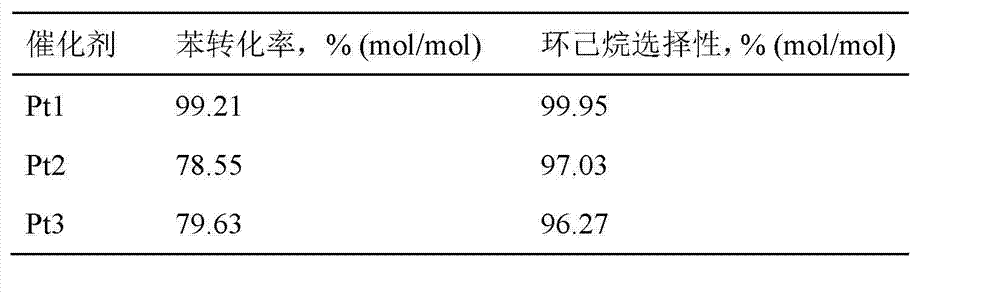

[0018] Example 3, Preparing Pt / Al with Tetraammine Platinum (II) Acetate as a Precursor 2 o 3 catalyst

[0019] Immerse the alumina carrier in 30 ml of 0.05 mol / L tetraammine platinum acetate solution, soak for 5 hours at room temperature, drain, dry at 120°C for 4 hours, and then bake at 500°C for 4 hours to obtain a content of 0.3 %Pt / Al 2 o 3 Catalyst Pt1 of the catalyst; chloroplatinic acid and platinum nitrate solutions were used as precursors to prepare Pt / Al with a content of 0.3% by the same method as above 2 o 3 Catalysts Pt2 and Pt3.

[0020] Taking the hydrogenation of benzene to cyclohexane as a reaction model to investigate their catalytic activity, the reaction conditions are: a mixture of hydrogen and benzene (2000: 1) was introduced at 170°C and 3 MPa. The reaction results of the above catalysts are shown in the following table:

[0021]

[0022] It can be seen from the above table that the performance of the catalyst for the hydrogenation of benzene t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com