Fuel synchronous superposition treatment device and method

A technology of superposition processing and fuel oil, which is applied in the direction of refining by particle radiation, refining by electricity/magnetism, dehydration by electricity/magnetism/demulsification, etc. problems, to achieve the effect of improving fluidity, enhancing stability, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

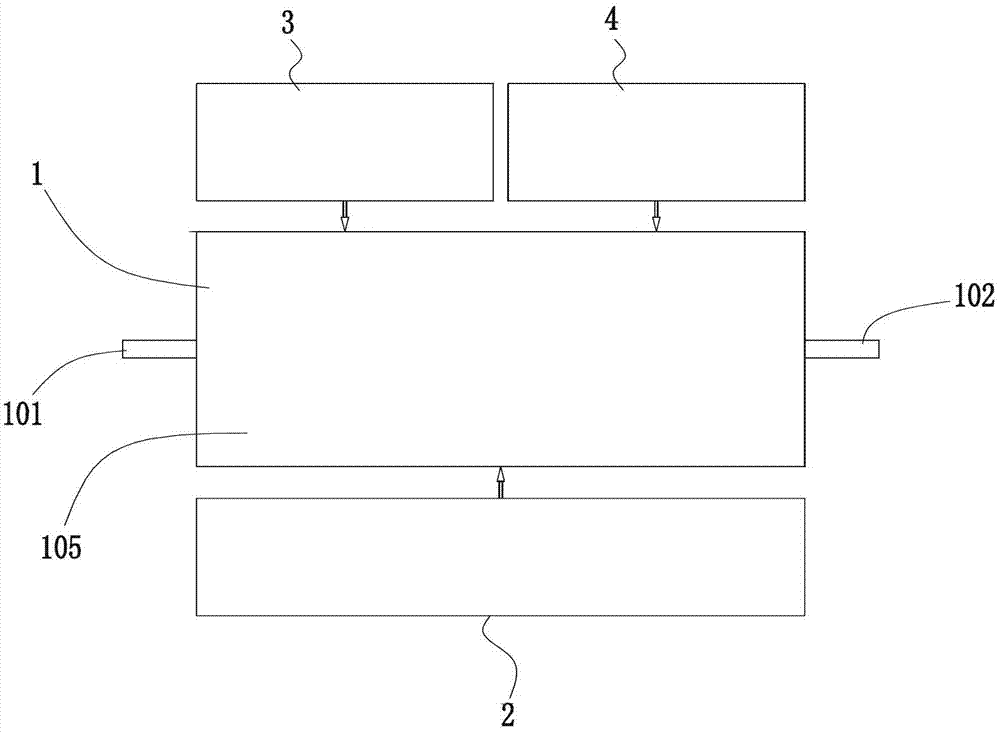

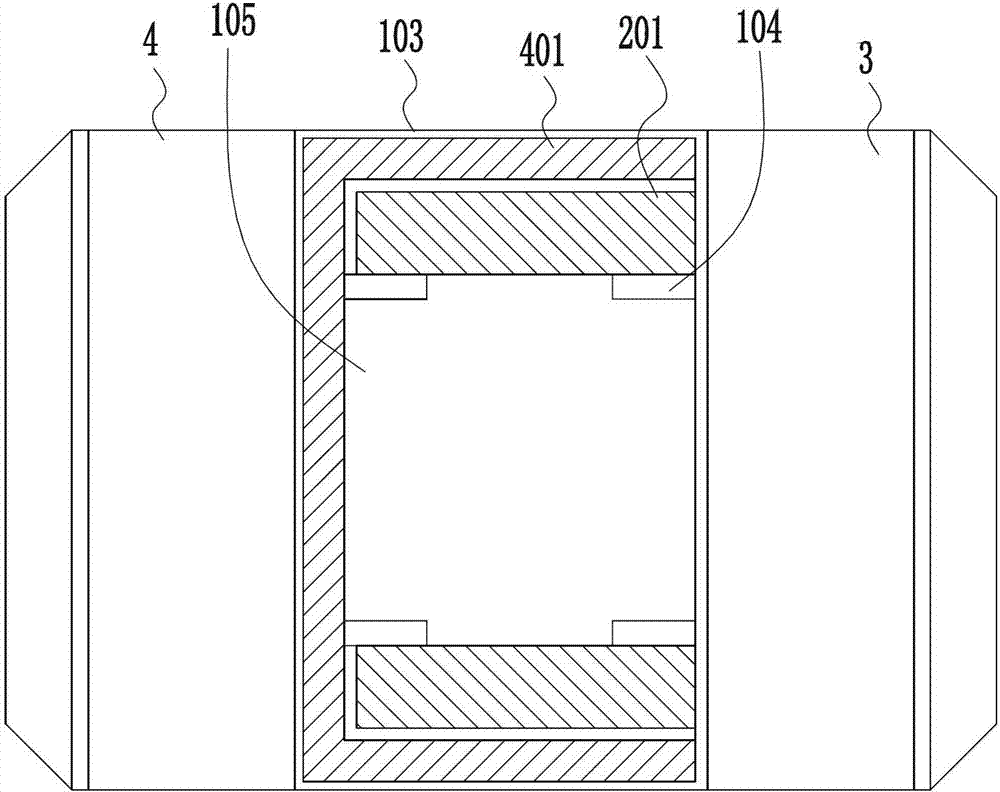

[0031] Preferred Embodiment 1: Embodiment 1 of the present invention provides a fuel oil synchronous superposition processing device, which includes an energy receiving chamber 1 , a magnetization energy device 2 , an ultrasonic energy device 3 and an electromagnetic wave energy device 4 . Both the ultrasonic energy device 3 and the electromagnetic wave energy device 4 are installed outside the energy receiving chamber 1 , and the magnetization energy device 2 is installed inside the energy receiving chamber 1 .

[0032] The energy receiving chamber 1 includes a rectangular frame body 103 and a cavity 105 formed in the frame body 103. The frame body 103 is provided with an oil passage inlet 101 and an oil passage outlet 102 communicating with the cavity 105. The oil passage The inlet 101 and the oil passage outlet 102 are respectively arranged on both sides of the frame body 103 ; the inside of the energy receiving chamber 1 is provided with a bracket 104 for fixing and install...

Embodiment 2

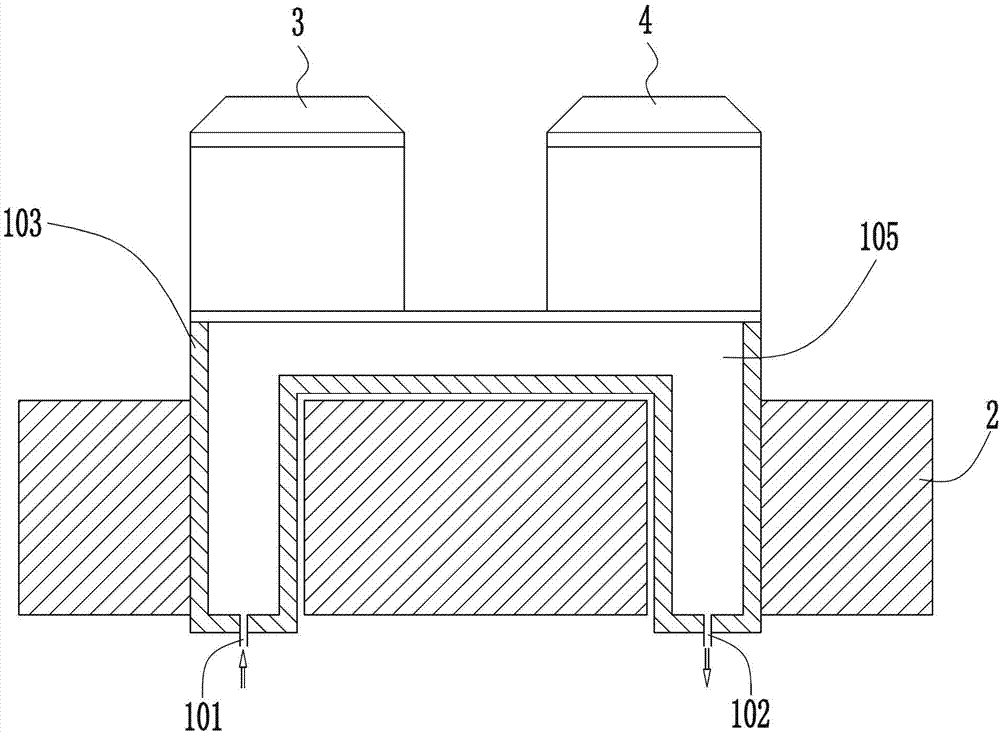

[0036] Preferred Embodiment 2: Embodiment 2 of the present invention provides a fuel oil synchronous superposition processing device, which includes an energy receiving chamber 1 , a magnetization energy device 2 , an ultrasonic energy device 3 and an electromagnetic wave energy device 4 . The magnetization energy device 2 , the ultrasonic energy device 3 and the electromagnetic wave energy device 4 are all installed outside the energy receiving chamber 1 .

[0037] The energy receiving chamber 1 includes a U-shaped frame body 103 and a cavity 105 formed in the frame body 103, the two ends of the U-shaped frame body 103 are respectively provided with an oil passage inlet 101 and an oil passage outlet communicated with the cavity 105 102.

[0038] The magnetization energy device 2 is installed outside the energy receiving chamber 1 and can generate a magnetic field strength of 0.1~10MT (in this embodiment, the magnetic field strength is preferably 0.4MT), which includes a perma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com