High-precision cold headed wire product treatment process and equipment

A technology for processing technology and upsetting finished products, which is applied in the field of processing technology and equipment for cold heading finished wire, which can solve problems such as cracking and impact on the service life of molds, and achieve the effects of uniform temperature, high spheroidization rate and sufficient protective atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

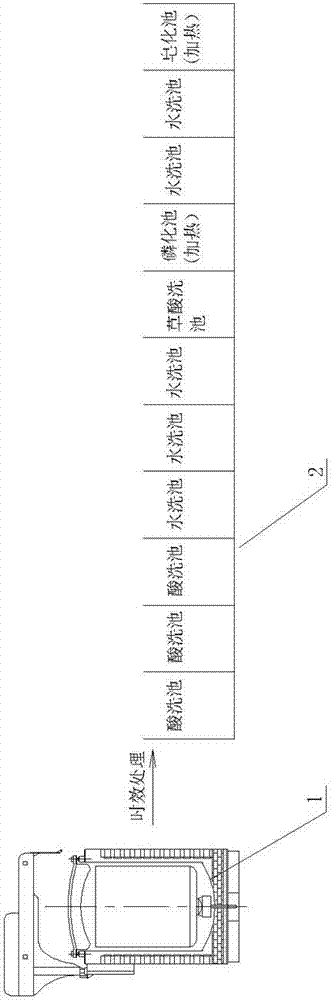

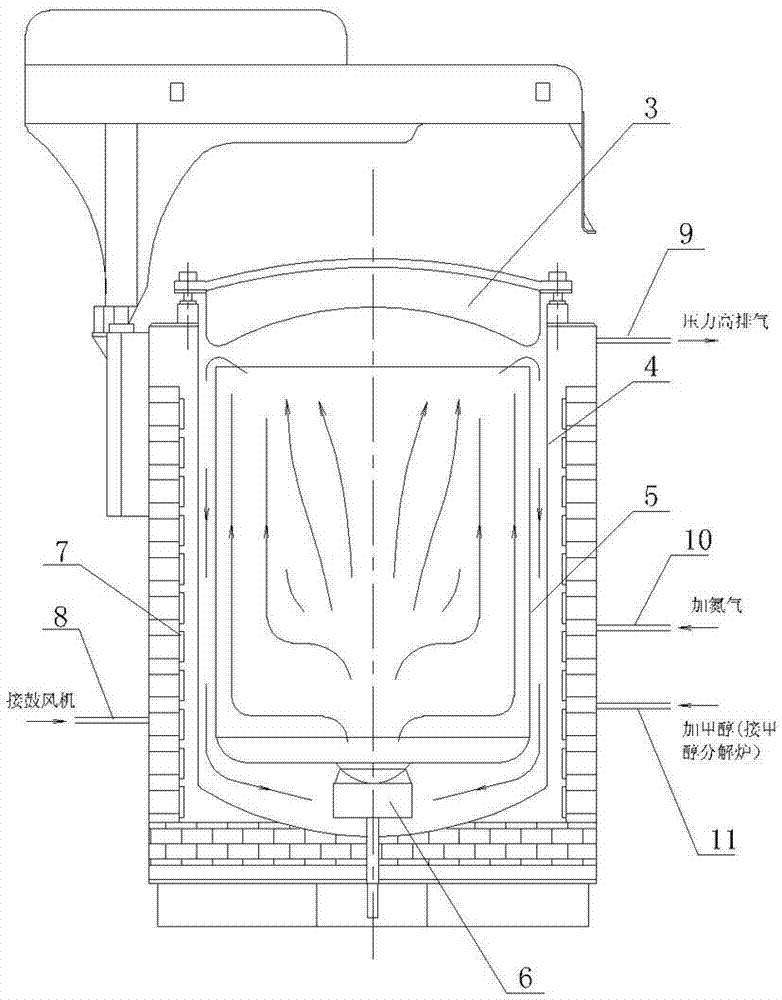

[0012] figure 1 , 2 As shown, the equipment for implementing high-precision cold heading finished wire processing technology includes a spheroidizing annealing furnace 1 and a treatment pool 2. The spheroidizing annealing furnace has an outer furnace 4, an inner furnace 5, a furnace cover 3 and a centrifugal fan 6, and the inner furnace 5 Located in the outer furnace 4, the bottom of the furnace cover 3 facing the top of the inner furnace 5 is a spherical arc, the outer furnace 4 is equipped with an electric heating device 7, and the centrifugal fan 6 is installed on the bottom of the inner furnace 5 Between the furnace and the bottom of the outer furnace, when the centrifugal fan is working, a forced convection circuit is formed between the inner furnace, the gap between the inner furnace roof and the furnace cover, the inner furnace and the outer furnace wall, and the inner furnace and the outer furnace bottom gap , the annealing furnace is provided with nitrogen inlet 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com