Normal-pressure multichannel papermaking drying cylinder

A paper-making dryer, multi-channel technology, applied in papermaking, papermaking, textiles and papermaking, etc., can solve the problems of difficult processing and sealing, which cannot be applied, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

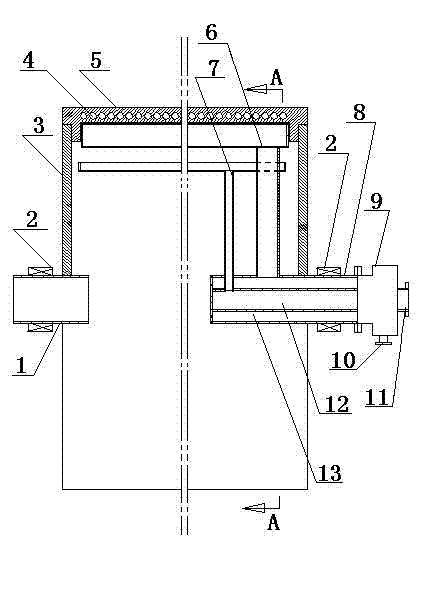

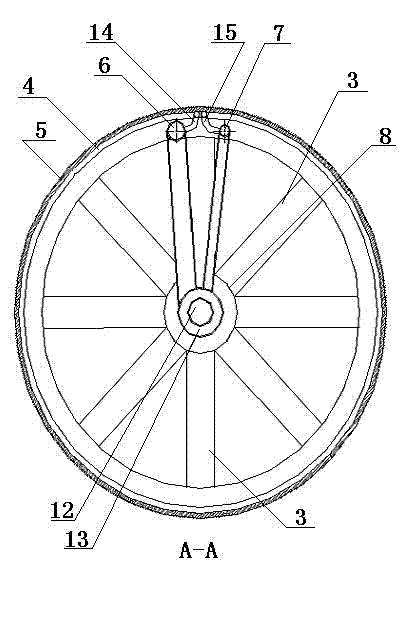

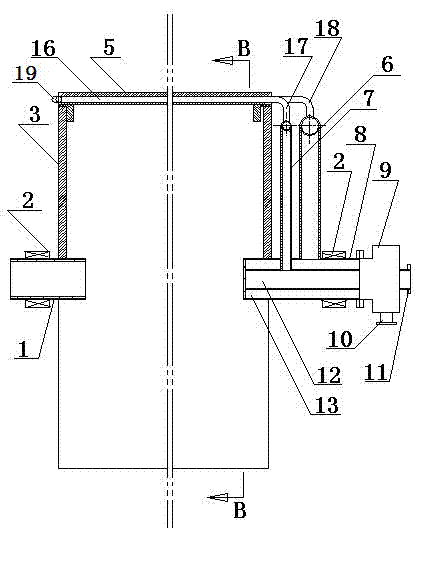

[0016] Below in conjunction with accompanying drawing, the present invention will be further described.

[0017] figure 1 As shown, it is a schematic cross-sectional structure diagram of the transverse annular cloth heat conduction channel of the present invention; figure 2 shown, is figure 1 The schematic diagram of the structure along the line A-A. combine two Figure 1 From the looks of it, the cylinder block includes a left shaft 1, a bearing 2, a spoke 3, a cylinder wall 5 and a right shaft 8. Wherein, the inner sides of both ends of the cylinder wall 5 are respectively fixedly connected with the two spokes 3, and the middles of the spokes 3 on both sides are respectively fixedly connected with the left shaft 1 and the right shaft 8, and the left shaft 1 and the right shaft 8 may be the same shaft; Bearings 2 are arranged on the outer sides of the shaft 1 and the right shaft 8 respectively. In the cylindrical cylinder wall 5, a number of horizontal heat conduction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com