Micro-switch type automotive central door lock fastener and production process thereof

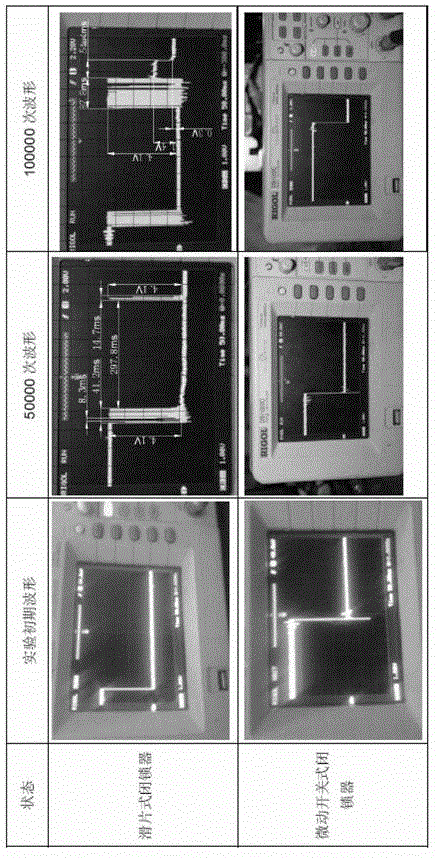

A technology of micro switches and lockers, which is applied in electric locks, vehicle locks, building locks, etc., can solve the problem of increased contact resistance of locker reeds and sliders, manufacturers cannot effectively control contact characteristics, and resistance value fluctuation time Over length and other issues, to achieve the effect of improved signal quality, simple structure, and reduced product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

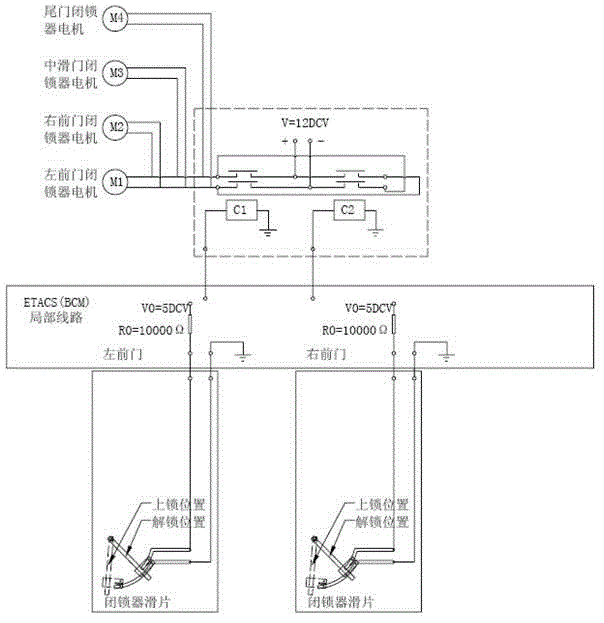

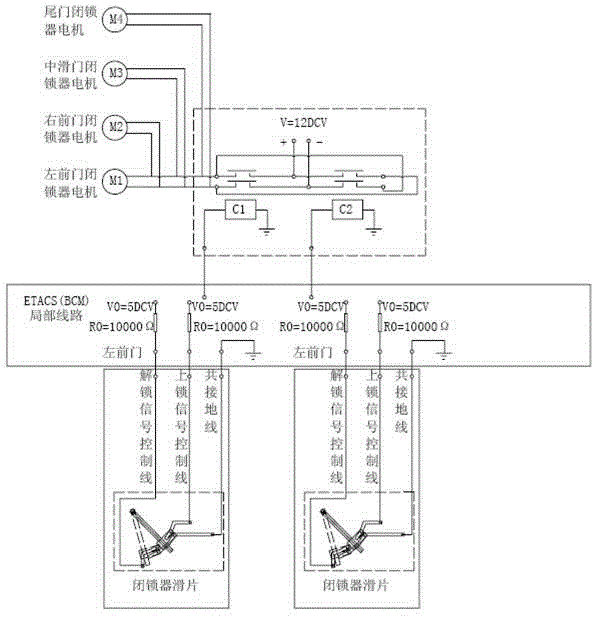

[0058] A micro-switch type automobile central control door lock locker, including a shaft clamp spring, a locker action output swing rod, a sealing ring, a reset torsion spring, a worm wheel, a locking buffer pad, a locker output shaft, a sector gear, an unlocking Buffer block, driving cam block, worm gear shaft, lower housing of the lock, motor electrodes, micro switch terminal, micro switch, motor, pinion, worm, upper housing of the lock;

[0059] The output shaft of the locker and the driving cam block are integrally injected to ensure dimensional stability, and the integral injection molded parts are put into the sector gear, the upper shell of the locker, the sealing ring, the action output swing rod of the locker, and then clamped by the shaft circlip on the locker The corresponding position of the shell is assembled with the reset torsion spring, worm gear, locking buffer pad, and unlocking buffer block. The worm gear is in a natural state, that is, the reset torsion spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com