Safe energy-saving dust-proof mosquito-proof glass jalousies and manufacture method thereof

A manufacturing method and shutter technology, which are applied in the direction of defense against harmful radiation, insect control, and theft prevention, to achieve the effects of delaying fading, increasing appearance aesthetics, and improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

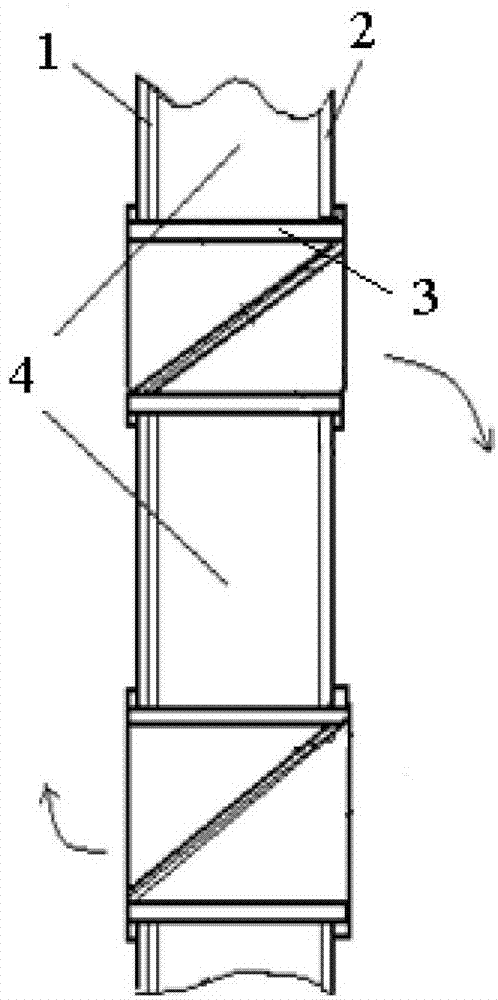

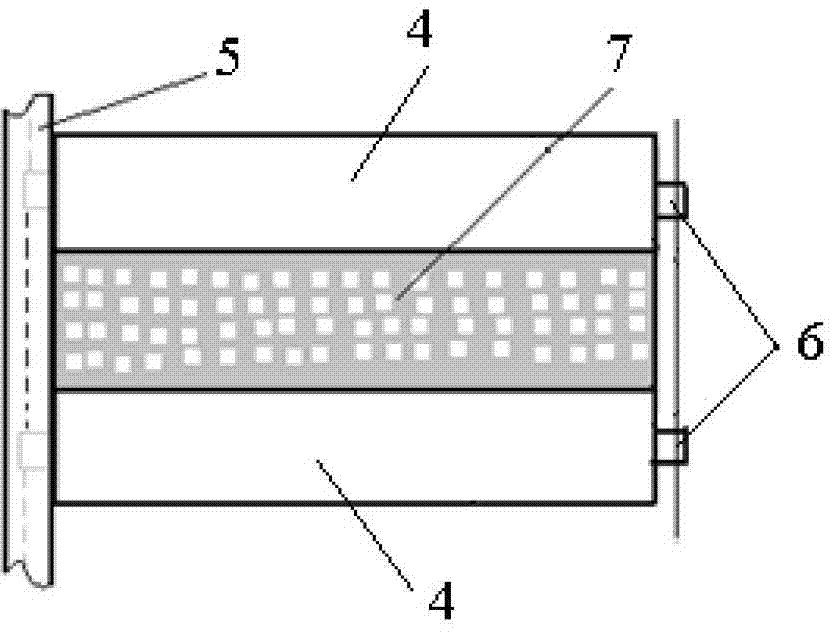

[0038] Example 1: Use a piece of ordinary flat glass of 800×160mm×3mm, another piece of heat-insulating glass or flat glass with the same area of 3mm, there is a heat-insulating film between the two pieces of glass, and a 0.55mm PVB film is used for the heat-insulating film to be inward. The safety enhanced glass process is prepared into a glass sandwich film; then it is made into a hollow glass strip with a piece of ordinary flat glass with the same area of 800×160mm×4mm; it is made of a rectangular alloy frame with a connecting structure at the top of the rod and a parallelogram in cross-sectional area. Hollow glass louvers; alloy window frame 800×1700mm, the net dimensions of the two mullions relative to each other are 90mm, 170mm, ..., 90mm, and the installation holes for fixing the hollow glass louvers are made on the vertical center line. The sheets are connected with a 5-mesh air filter to prepare a hollow glass louver mosquito-proof window.

Embodiment 2

[0039]Example 2: Use a piece of 1000×180×3mm ordinary flat glass and another piece of 3mm low-heat radiation flat glass with the same area. The beige PVB film is prepared into a glass sandwich film by the safety-enhanced glass process; then it is made into a hollow glass strip with a piece of ordinary flat glass with a screen printing pattern of 1000×170×4mm; a rectangle with a connecting structure at the top of the rod, and the cross-sectional area is parallel Quadrilateral, quadrilateral alloy frame with 45-degree sharp corners is made of hollow glass louver, alloy window frame 1000×1810mm, and the inner dimensions of the two vertical frames are 100mm, 190mm, ..., 100mm, fixed on the vertical center line Mounting holes for insulating glass louvers. The sheets are connected with a 15-mesh air filter to prepare a hollow glass louver mosquito-proof window.

Embodiment 3

[0040] Embodiment 3: the flat glass with low heat radiation 1200 × 200 × 3mm flat glass and the same area of 4mm inorganic material coating screen printing pattern, there is a film layer between the two flat glasses, and the film layer is used in phase The 0.75mm PVB film is made into a laminated glass plate by the safety enhanced glass process; it is made into a hollow glass strip with a 5mm flat glass of the same area; a rectangle with a connecting structure at the top of the rod, a parallelogram in cross-sectional area, and a quadrilateral sharp corner The hollow glass louver is made of a 45-degree alloy frame, the machine material coating screen printing pattern is facing outward, the alloy window frame is 1200×2100mm, and the net dimensions of the two mullions are 110mm, 210mm, ..., 110mm in the vertical center line, and punch the mounting holes for fixing the hollow glass louvers. The sheets are connected with a 30-mesh air filter to prepare a hollow glass louver anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com