Spinning defective cloth detection camera and detection system thereof

A detection system and camera technology, applied in the direction of electrical testing/monitoring, etc., can solve the problems of long data transmission distance, easy to be interfered, complex installation, low detection accuracy of infrared scanning mode, etc., to facilitate wiring installation and later maintenance, and reduce system cost. cost, the effect of improving recognition accuracy and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

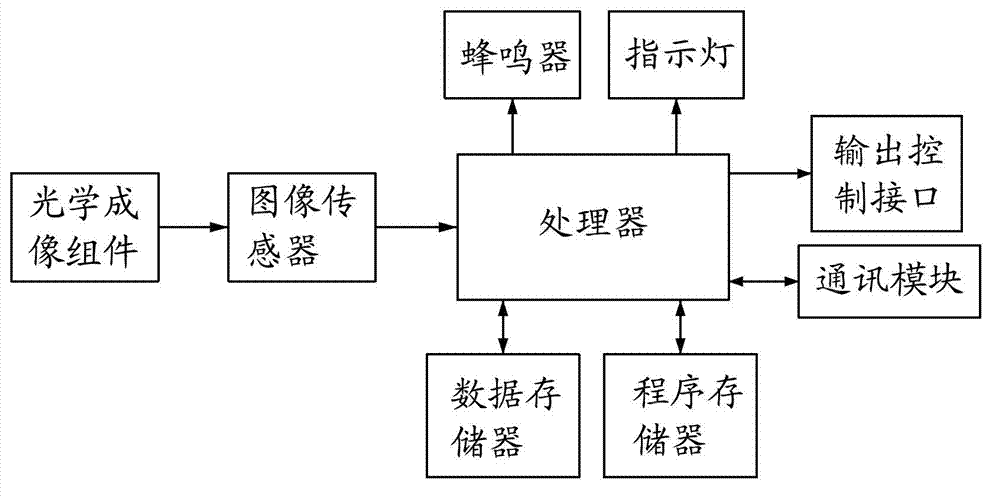

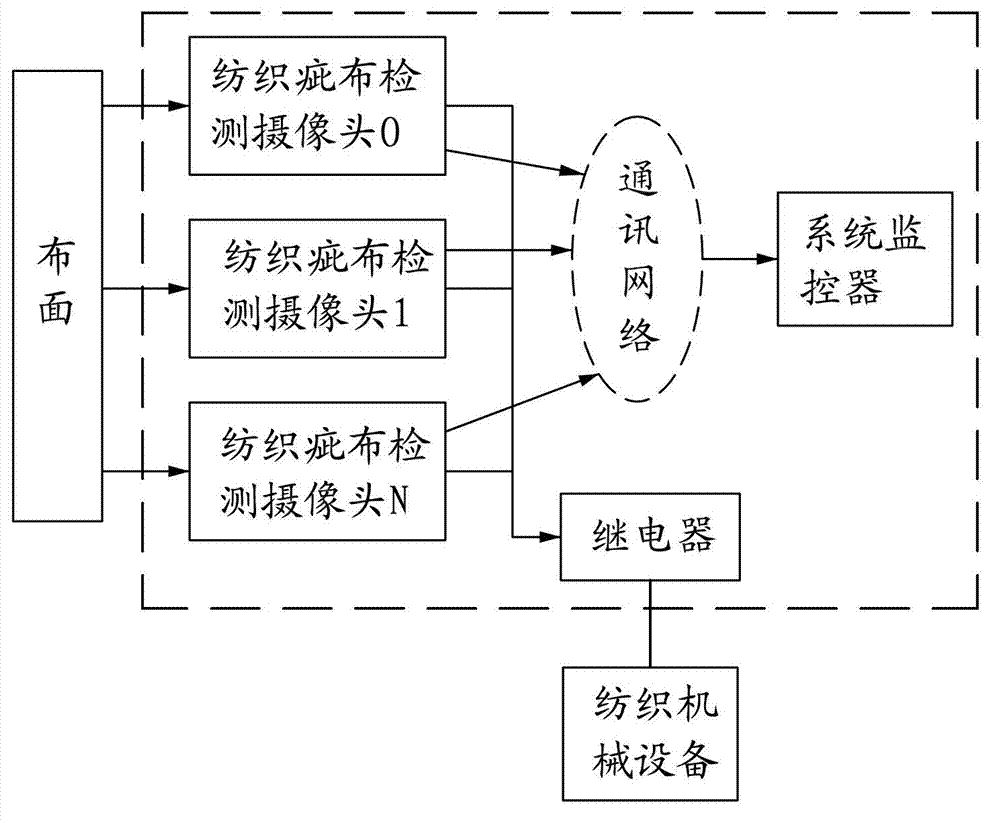

[0013] see figure 1 As shown, a textile defect detection camera of the present invention includes an optical imaging component, an image sensor, a processor, a data memory, a program memory, a communication module, a buzzer and an output control interface; the optical imaging component and the image sensor connection; the image sensor, data storage, program storage, communication module, buzzer, and output control interface are all connected to the processor; the optical imaging component images the textile cloth on the image sensor, and the image sensor converts the optical The image signal is converted into electrical information and communicated with the processor. The processor stores the electrical information in a data memory, and the program memory stores intelligent algorithms, including: wavelet filtering, neural network algorithms, and Canny (edge). detection) algorithm; the processor invokes an intelligent algorithm to analyze the electrical information in the data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com