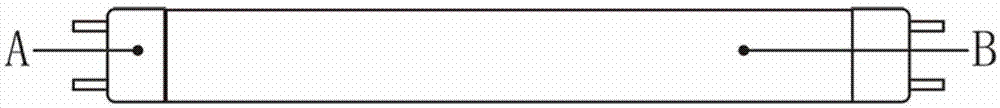

Double-layer tube efficient mercury-free energy-saving lamp

A double-layer tube, energy-saving lamp technology, which is applied to the parts and components of gas discharge lamps, can solve problems such as the service life of mercury pollution, and achieve the effects of prolonging the service life, reducing mercury pollution and improving light efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

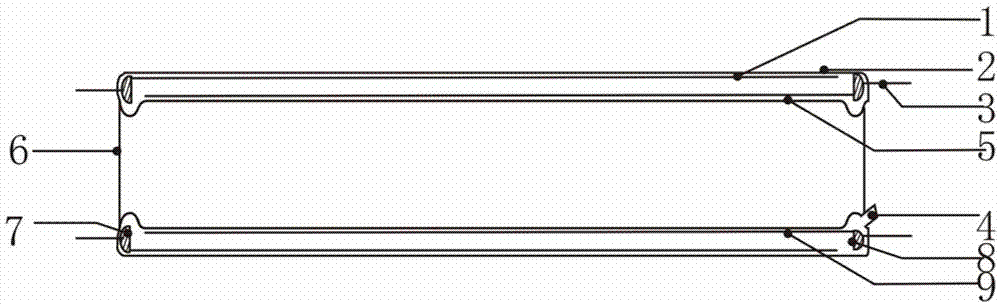

[0008] The inside of the outer layer tube 2 is coated with phosphor coating 1, and the conductive material 7 for connecting the conductive layer of the outer layer tube is placed in the groove of the inner layer tube 5 and bonded firmly, and the outer wall of the inner layer tube 5 Coat the phosphor layer 9 with a conductive layer, place the conductive material 8 connecting the conductive layer of the inner tube into the groove of the inner tube and bond it firmly, and sinter the inner tube 5 and the outer tube 2 together by machine , lead wire 3 on the sintering end 6 of the inner and outer tubes, and weld the exhaust pipe 4 on the sealing of the inner and outer tubes. The upper exhaust truck extracts the miscellaneous gas in the double-tube high-efficiency mercury-free energy-saving lamp, and injects neon and other inert gases. The double-tube high-efficiency mercury-free energy-saving lamp tube is completed. The electronic circuit can light the double-tube high-efficiency m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com